Cold rolling roller with high-roughness surface and manufacturing method of cold rolling roller

A manufacturing method and technology for cold rolling rolls, applied in the field of roll manufacturing, can solve problems such as low roughness, achieve the effects of fine and uniform grains, reduced grinding consumption, and uniform roll body structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The manufacturing method of the cold rolling roll with high-roughness surface of the present embodiment comprises the following process steps:

[0046] 1) Prepare steel raw materials according to the chemical composition and weight percentage in the material of the cold roll, and prepare the roll blank according to a certain production process.

[0047] Specifically, the steel raw materials are smelted in an electric arc furnace and a refining furnace, and molded into electrode ingots. The chemical composition and weight percentage are tested. After passing the test, it is forged into a forging billet. The forging billet is subjected to post-forging heat treatment, and finally turned to obtain a roll billet.

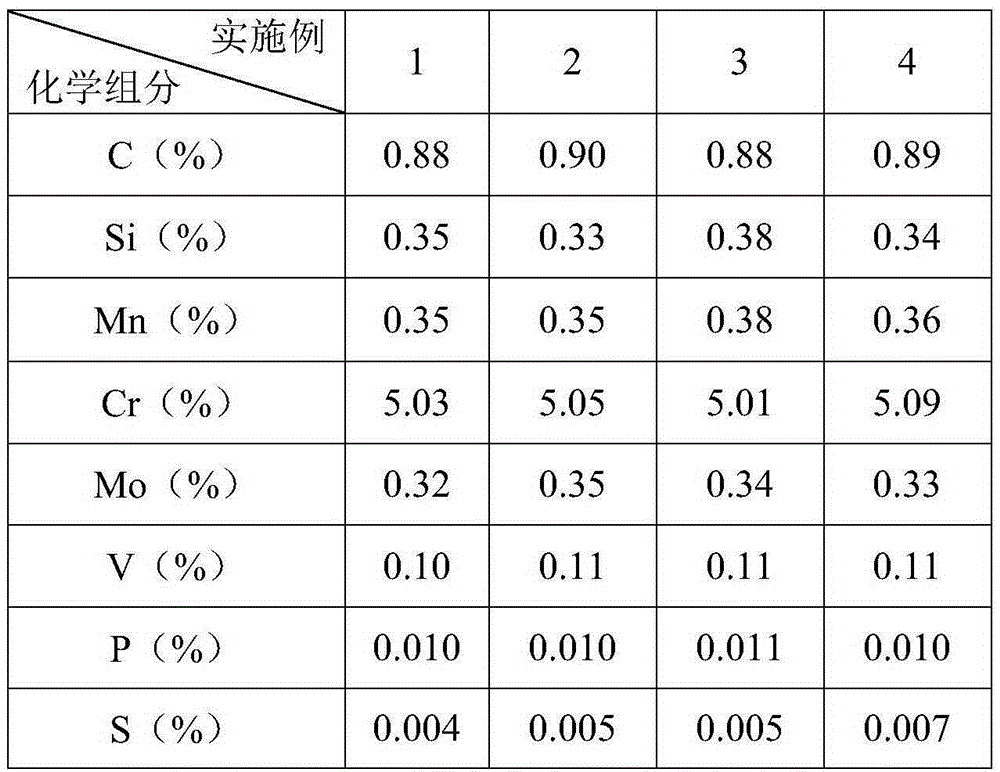

[0048] The test results of the weight percentage of the main chemical components in the material of the cold roll of this embodiment are shown in the column of Example 1 in Table 1, and the rest are Fe and unavoidable impurities.

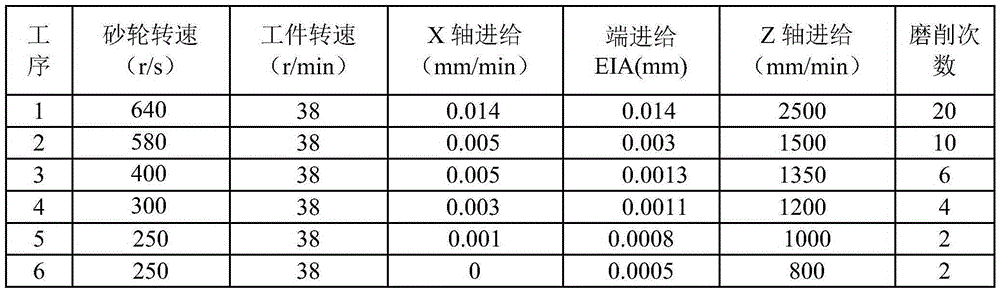

[0049] 2) Carry out rough turni...

Embodiment 2

[0059] The cold rolling roll with high roughness surface of the present embodiment, the weight percentage of various chemical components in its material is tested, and the content of main components is shown in column 2 of embodiment in table 1, and the rest is Fe and cannot Avoid impurities.

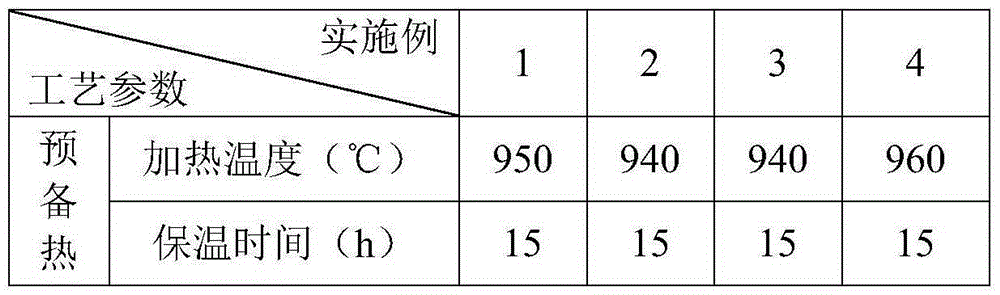

[0060] The manufacturing method of the cold rolling roll with the high-roughness surface of the present embodiment, its processing step is similar to embodiment 1, and the concrete heat treatment parameter that differs from embodiment 1 is shown in column 2 of embodiment 2 in table 2, and specific grinding treatment Parameters are the same as in Example 1.

[0061] The roll surface hardness of the cold roll produced in this example is 94-96 HSD, and the roll surface roughness obtained after grinding the cold roll is Ra0.435-0.467 μm.

Embodiment 3

[0063] The cold rolling roll with high roughness surface of the present embodiment, the weight percentage of various chemical components in its material is tested, and the content of main component is shown in column 3 of embodiment in table 1, and the rest is Fe and can not Avoid impurities.

[0064] The manufacturing method of the cold rolling roll with the high-roughness surface of the present embodiment, its processing step is similar to embodiment 1, and the specific heat treatment parameter that differs from embodiment 1 is shown in column 3 of embodiment 3 in table 2, and specific grinding treatment Parameters are the same as in Example 1.

[0065] The roll surface hardness of the cold roll produced in this example is 95-96 HSD, and the roll surface roughness obtained after grinding the cold roll is Ra0.441-0.482 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com