Construction method for light steel skeleton special-shaped model suspended ceiling

A construction method, the technology of light steel keel, applied in the direction of ceiling, building structure, building components, etc., can solve the problems of easy cracking, deformation, high-intensity labor, repeated work surface, etc., to achieve small deformation and reduce manpower low investment and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

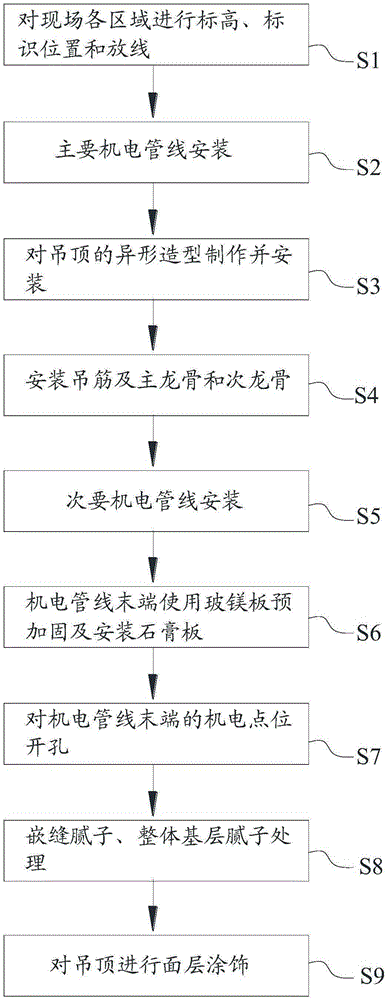

[0029] like figure 1 The construction method of the light-steel framework special-shaped shaped ceiling includes the following steps:

[0030] S1. Elevation, marking position and setting out of each area on the site;

[0031] S2. Installation of main mechanical and electrical pipelines;

[0032] S3. Make and install the special-shaped shape of the suspended ceiling;

[0033] S4. Install hanging ribs, main keel and secondary keel;

[0034] S5. Secondary mechanical and electrical pipeline installation;

[0035] S6. The end of the electromechanical pipeline is pre-reinforced with glass magnesium board and installed with gypsum board;

[0036] S7, opening holes at the electromechanical points at the end of the electromechanical pipeline;

[0037] S8, caulking putty, overall grass-roots putty treatment;

[0038] S9. Carry out surface coating to the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com