Control method for coal impact disasters in coal mining

A technology for coal mass and disasters, which is applied in mining equipment, mining equipment, earth-moving drilling, etc., can solve the problems of insufficient prevention and control methods, single pressure relief measures, and insufficient effect, so as to eliminate coal mass slippage, instability or other problems. The effect of crushing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below.

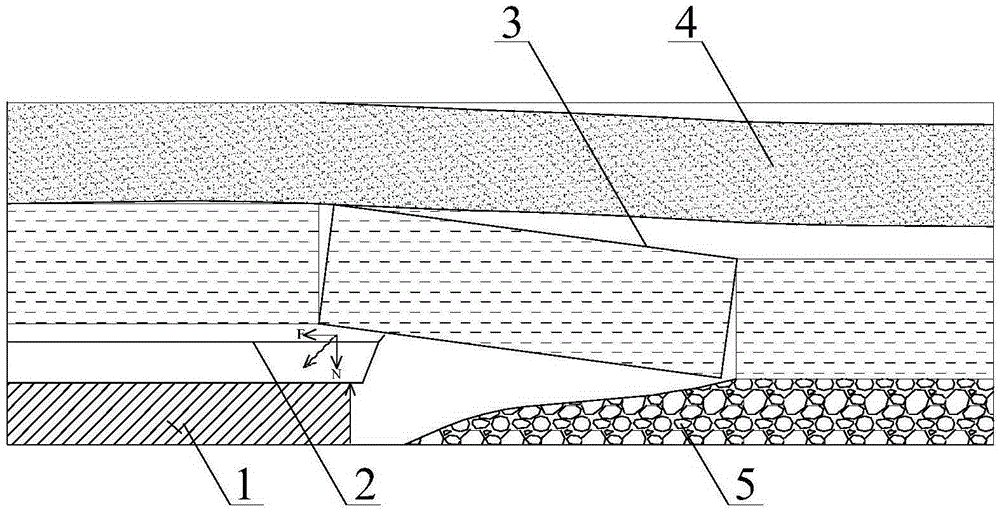

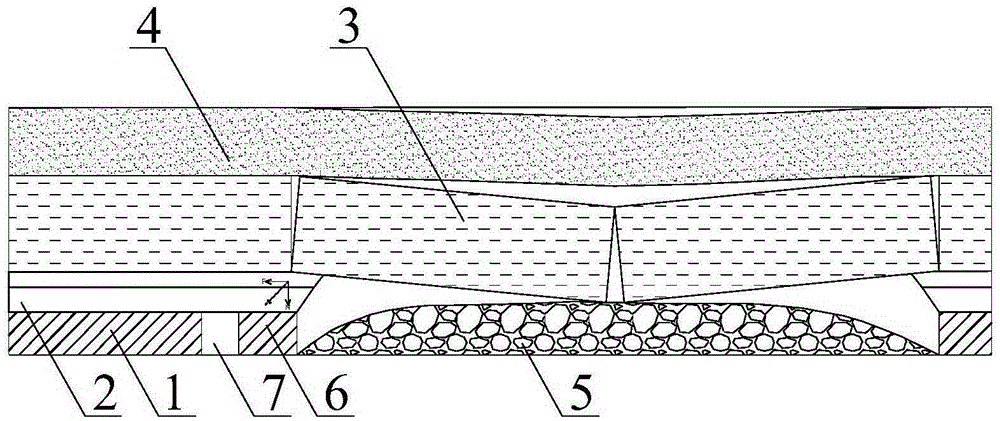

[0021] Such as Figure 1 to Figure 4 Shown, concrete steps of the present invention are:

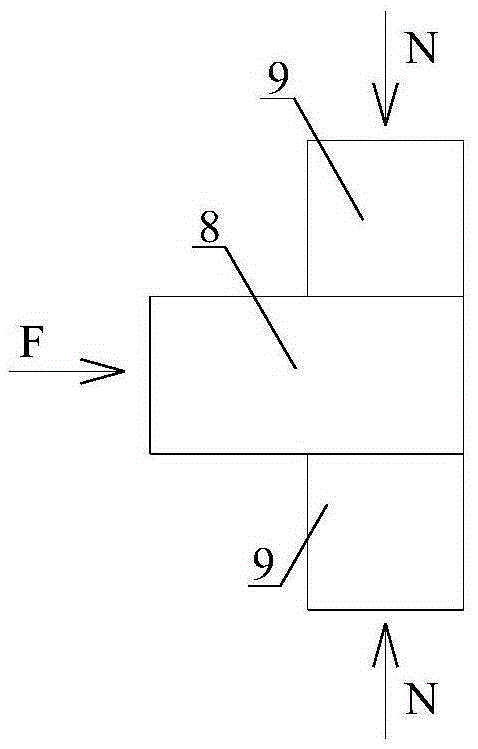

[0022] A. Determining the coefficient of frictional resistance: collect the coal body sample 8 and the top and bottom slate sample 9 from the mining site of the mine, and determine the friction coefficient of the coal body sample 8 and the top and bottom slate sample 9 through laboratory stick-slip experiments and proportional calculations; specifically The coal rock sample is combined with the roof-bottom-coal seam to carry out the shear slip experiment in the laboratory. An axial force N is set, and a horizontal force F is applied to the coal sample 8 until the coal sample 8 slips. According to Shear stress and vertical stress calculate frictional resistance coefficient:

[0023] μ=F / N

[0024] B. Determine the relevant parameters for on-site implementation: before the underground mining of the coal mine, drill holes 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com