Medium-pressure and high-pressure air compressor set

A technology of high-pressure air and compressor units, which is applied in the direction of mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of low compressed air pressure, small displacement, and low efficiency, and achieve high exhaust pressure and large displacement , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

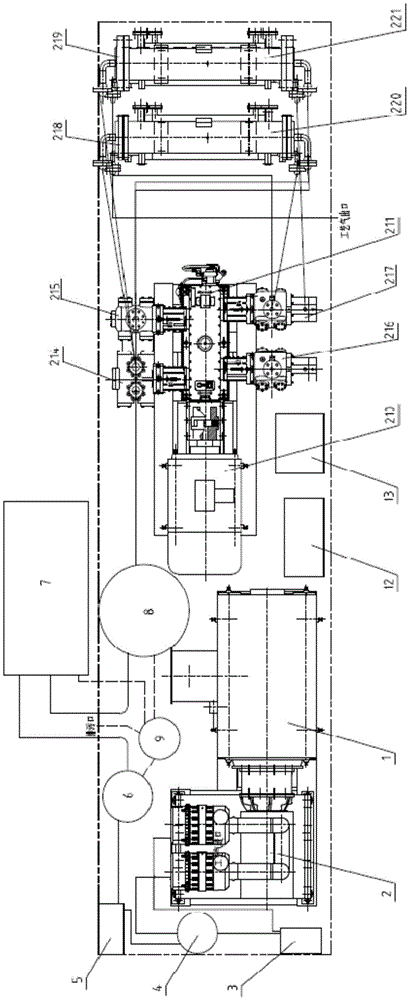

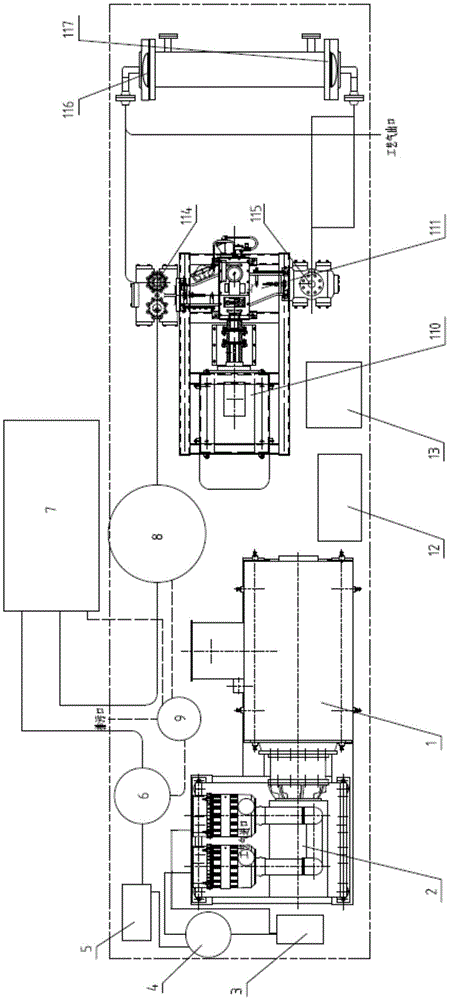

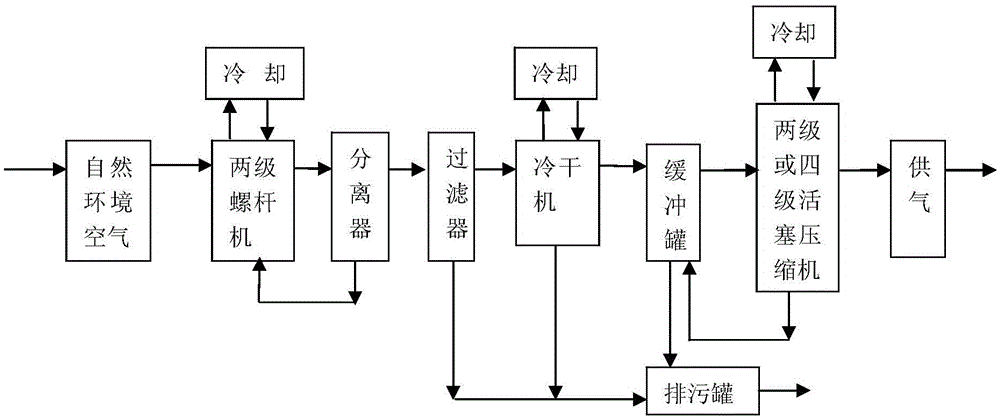

[0025] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0026] The medium-pressure or high-pressure air compressor unit of the present invention is a supercharging device that compresses natural ambient air through a screw compression system and a piston compression system, and the discharge pressure is above 6.3Mpa or above 32Mpa. The working medium is natural ambient air at 1 atmospheric pressure. The screw compression system pressurizes the natural ambient air to 1.5-2.5Mpa through two-stage compression. The ambient air is pressurized to above 6.3Mpa or above 32Mpa, and the system is cooled by water.

[0027] A medium-pressure or air compressor unit, including a screw compression system, a piston compression system, a filter, a cold dryer, a buffer tank, and a sewage tank; the screw compression system includes a two-stage screw compressor, which pressurizes the natural ambient air to 1.5~ 2.5Mpa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com