High anti-seismic self-adjusting elastic threaded connector, processing method and application method

A technology for threaded connectors and processing methods, which is applied in the direction of connecting components, threaded fasteners, screws, etc., to achieve the effects of fast and simple production, excellent seismic properties, and excellent toughness and elastic properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further understand the content of the invention, characteristics and effects of the present invention, the following examples are described in detail as follows:

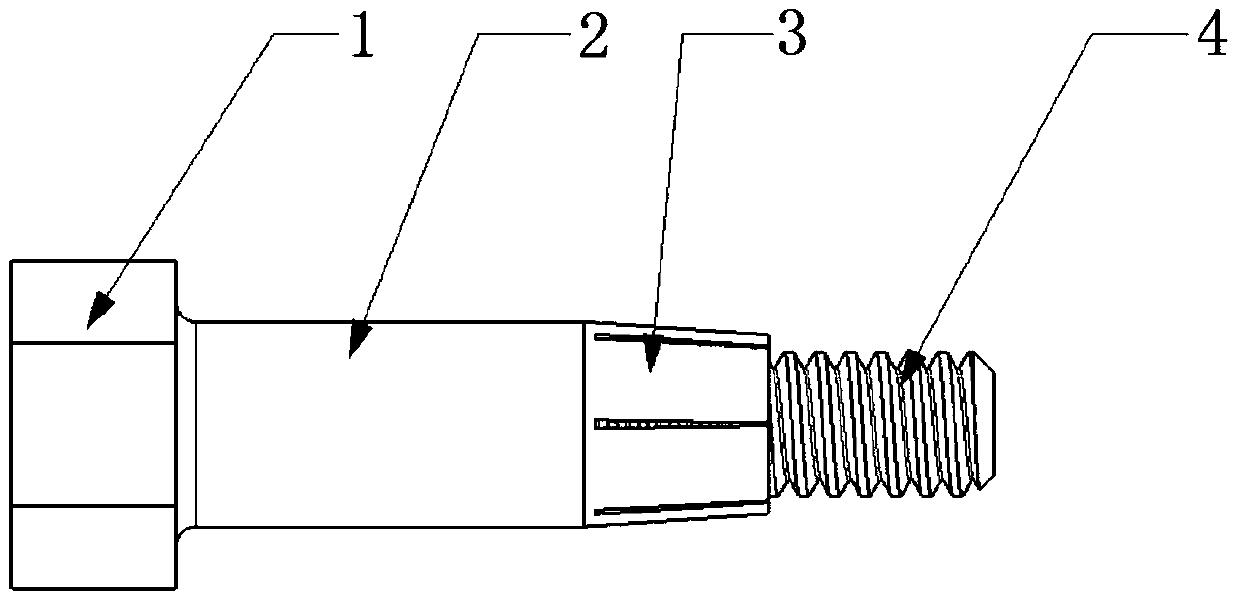

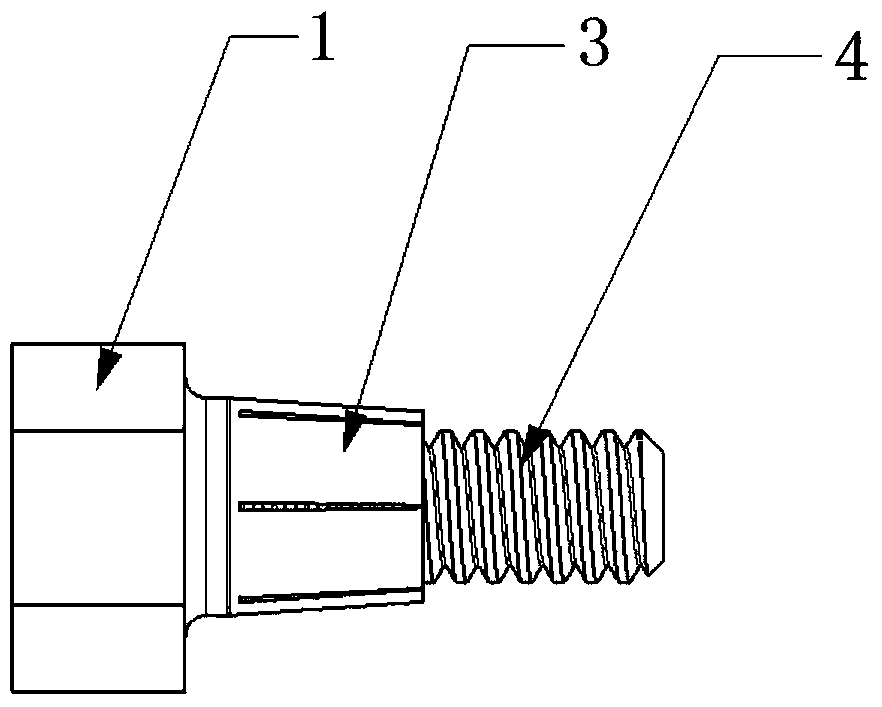

[0028] See Figure 1 to Figure 3 , One end of the threaded connector of the present invention is a supporting portion, and the other end is a connecting portion. The connection part includes a self-adjusting elastic ring 3 located on the outside, which bulges outward under the action of an axially compressed external force to form an elastic ring 9 of the outer drum, and a threaded rod 4 located on the inside.

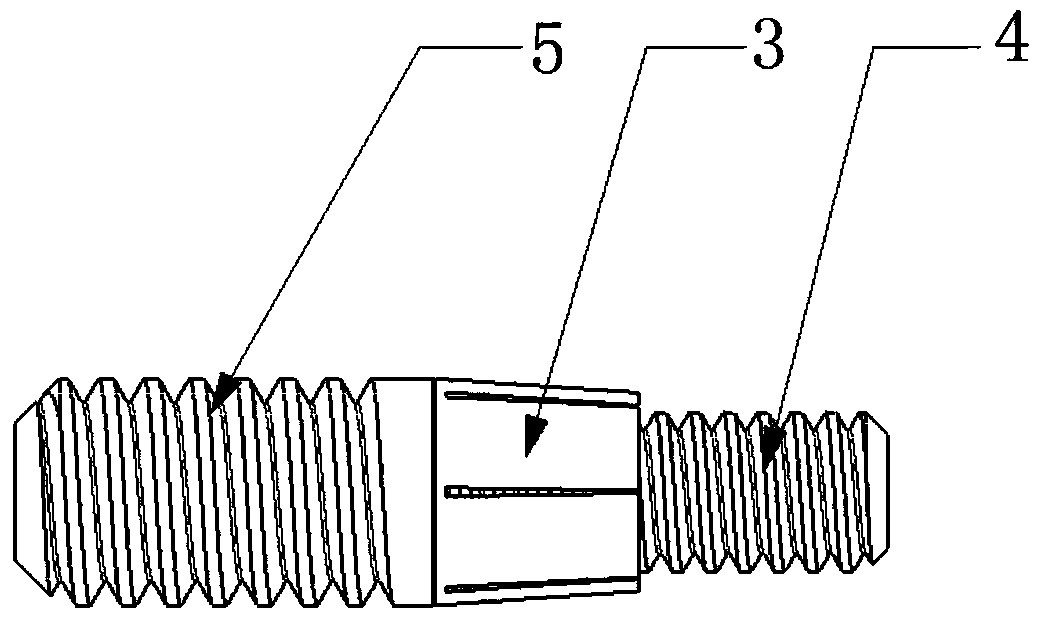

[0029] like Figure 7 and Figure 8 As shown in , the self-adjusting elastic ring 3 includes a plurality of elastic pieces 7 distributed along the circumferential direction, a wedge-shaped relief groove 8 is formed between two adjacent elastic pieces 7, and there is a gap between each elastic piece 7 and the threaded rod 4 and Each elastic sheet 7 is bent toward the threaded rod 4 . Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com