Whole-process control system for boiler water level

A technology of drum water level and control system, which is used in the control of water supply, steam generation, preheating, etc., can solve the problems of high operating pressure, waste of manpower and time, and reduce the automation level and efficiency of the unit, so as to avoid misoperation. Risk, reduce labor intensity, save absolute time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings. Here, the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

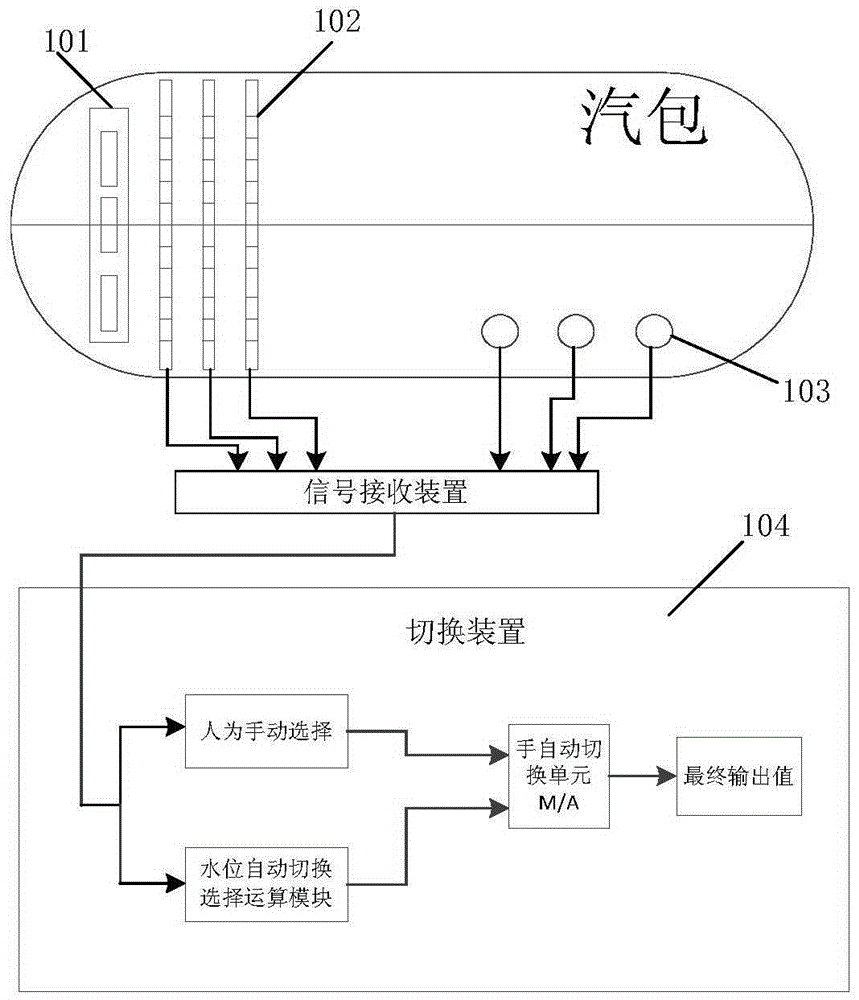

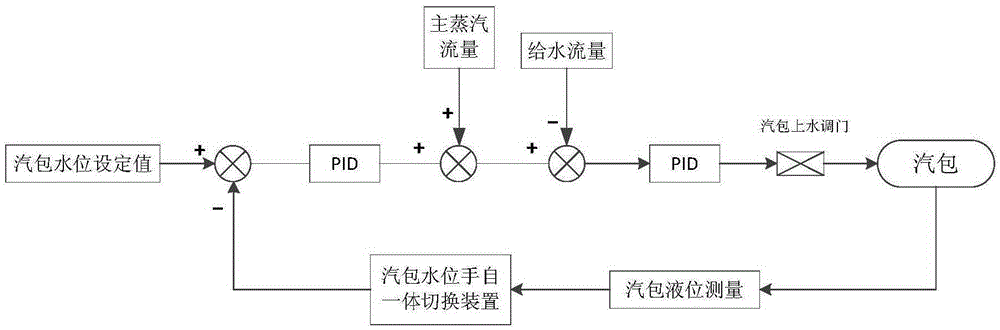

[0023] Please refer to figure 2 As shown, the present invention specifically provides a full-range control system for the steam drum water level, the system includes: a magnetic levitation water level device 102, a differential pressure water level device 103 and a switching device 104; the magnetic levitation water level device 102 is used to measure the steam drum water level in the boiler value, and output the steam drum water level value to the remote end; the differential pressure water level device 103 is used to obtain the steam drum water level value in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com