Machine vision based light-emitting panel detection method

A light-emitting panel and machine vision technology, applied in the field of detection, can solve the problems of "fitting, poor model adaptability, poor robustness, etc., and achieve the effect of smooth and convenient processing flow, wide range of implementation, and low implementation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

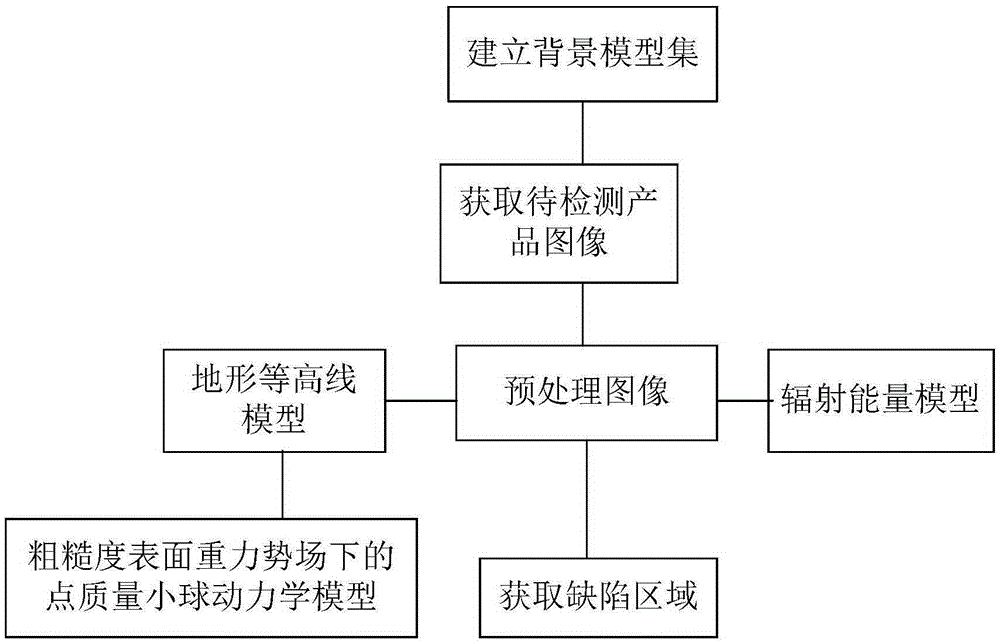

[0035] Such as figure 1 The light-emitting panel detection method based on machine vision is characterized in that it includes the following steps: first, a background model set is established. After that, the image of the product to be inspected is obtained, and the preprocessed image is obtained. Then, the preprocessed image is independently processed through the terrain contour model and radiation energy model. Finally, the previously processed data are synchronously summarized to obtain defect areas.

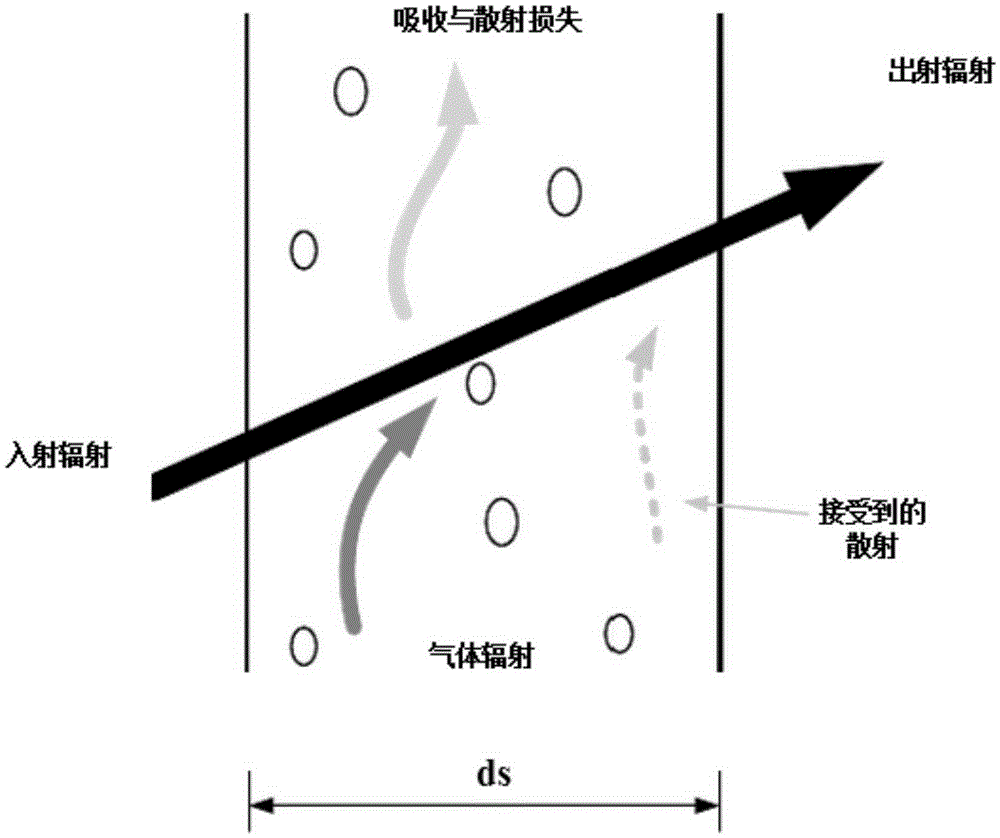

[0036] Such as figure 2 As shown, the radiant energy models involved in the present invention can be viewed from the common FLUENT software, and there are mainly fiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com