Method for inversion from electrical property of vertical interconnection structure to process parameter thereof

A technology of vertical interconnection and processing technology, which is applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., and can solve problems such as misalignment, interlayer misalignment, and uneven force on the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

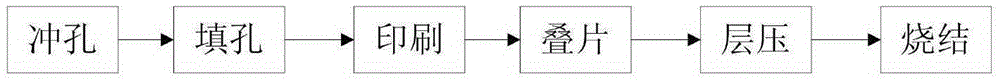

[0074] Such as Figure 5 As shown, the present invention provides a method of inversion from the electrical properties of the vertical interconnect structure to its processing parameters, comprising the following steps:

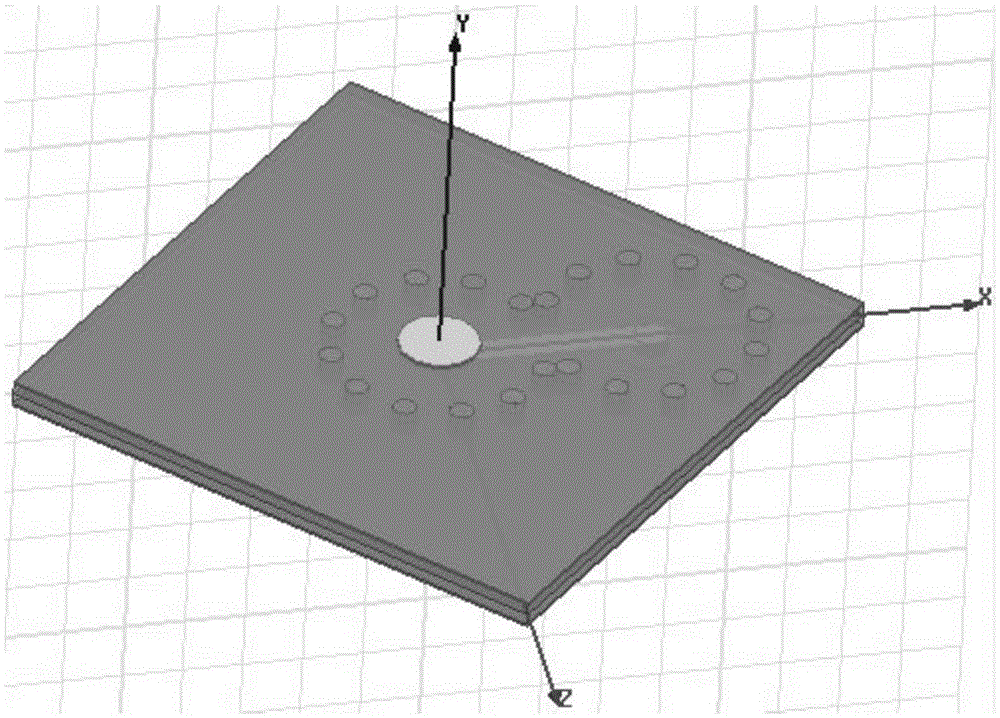

[0075] Step 1, using numerical simulation software to establish an electromagnetic simulation model of the undisplaced vertical interconnection structure, analyze and obtain the transmission resonant frequency and the value of S11 at the resonance of the undisplaced vertical interconnection structure, where S11 is the input reflection coefficient;

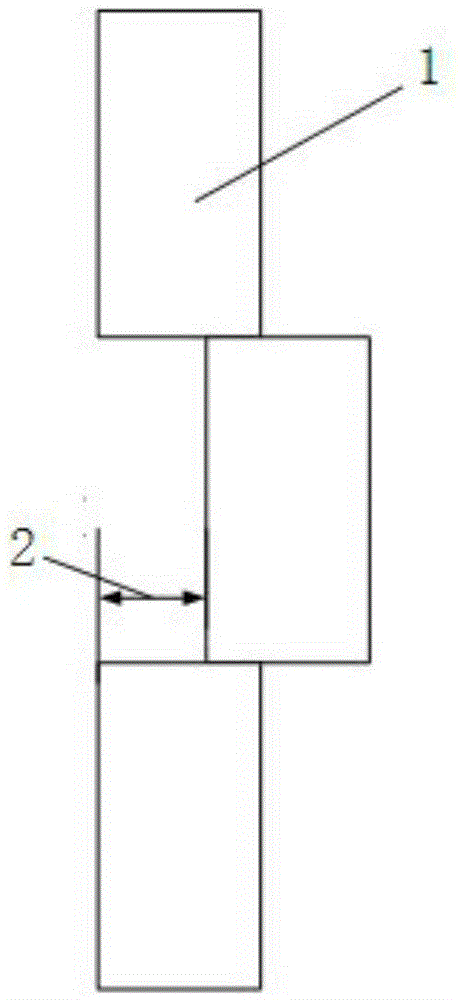

[0076] Step 2, according to the actual value of the processing parameters of the vertical interconnect structure, that is, the first temperature rise rate and the second temperature rise rate of the sintering curve actually used in the processing process, to determine the amount of misalignment between the layers of the vertical interconnect structure actual value;

[0077] The specific implementation process of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com