Production and separation method for flexible substrate

A technology of flexible substrates and separation methods, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problems of unsatisfactory yield and quality of flexible substrates, high cost of flexible OLED preparation, and achieve supporting facilities Improvement, wide application range, and the effect of reducing equipment procurement costs and process costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

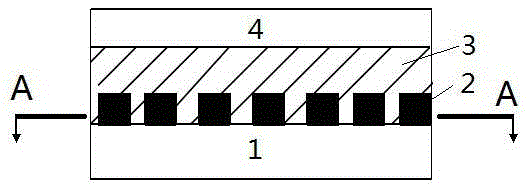

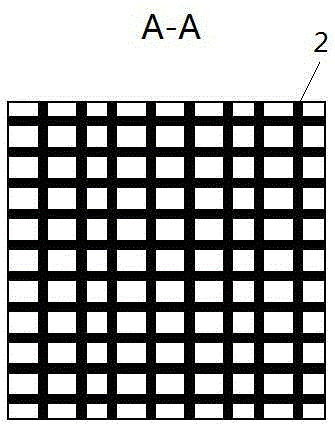

[0025] In this example, see Figure 1~3 , a preparation and separation method of a flexible substrate, using a rigid material substrate 1, the rigid material substrate 1 adopts a glass substrate, and sequentially prepare a grid-shaped continuous frame layer 2, a connecting layer 3 and a flexible substrate on the rigid material substrate 1 4. Form a grid-like layout, between the rigid material substrate 1 and the flexible substrate 4, combine the connecting layer 3 and the continuous frame layer 2 to form a combined layer, and fill the material for preparing the connecting layer 3 into the continuous frame layer 2, the upper surface of the combination layer is used as the surface of the carrier substrate for preparing the flexible substrate 4, and then the flexible substrate 4 is prepared on the upper surface of the combination layer, and then the subsequent film layer is prepared on the flexible substrate 4, wherein the continuous The frame layer 2 remains stable during the pr...

Embodiment 2

[0034] This embodiment is basically the same as Embodiment 1, especially in that:

[0035]In this embodiment, when the flexible substrate 4 is separated, the material of the continuous frame layer 2 is decomposed by using UV irradiation method, so that a grid-like continuous channel 5 is formed in the combined layer, so as to facilitate the subsequent implementation of the connecting layer 3. etch removal process. The method of this embodiment adopts the method of preparing a combined layer composed of a connecting layer 3 and a grid-shaped continuous frame layer 2 between a glass substrate and a flexible substrate 4, wherein the continuous frame layer 2 is stable under the conditions of the subsequent film layer preparation, and is stable in a specific treatment. Under the decomposition, the continuous frame layer 2 is decomposed and morphologically changed by changing the reaction conditions of UV irradiation, and a grid-like continuous channel 5 is formed in the connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com