Method of utilizing summer and spring fresh tea leaves to produce low-caffeine pineapple-flavor green tea

A technology of low caffeine and fresh tea leaves, which is applied in the direction of reducing the alkali content of tea and tea treatment before extraction, etc. It can solve the problems of low caffeine content, achieve low processing cost, convenient operation, and solve the effect of market obstruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

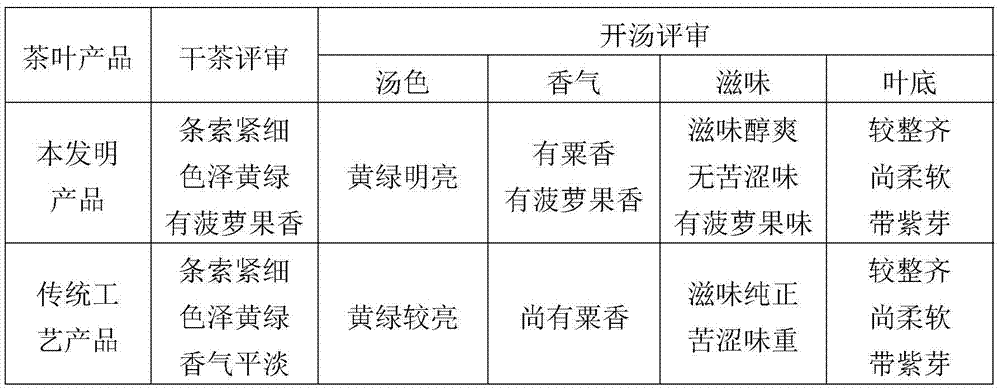

Image

Examples

Embodiment 1

[0039] The fresh leaves of the tea tree variety Bixiangzao in summer with one bud and two leaves are selected as raw materials.

[0040] Preparation of pineapple juice concentrate: Peel fresh pineapple, mash it with a tissue masher, then add pure water to the mashed pineapple according to the ratio of 1g pineapple to 2g purified water, mix well, and centrifuge at a speed of 16500 Centrifuge in a high-speed centrifuge at rpm, take the clear liquid, and concentrate it under reduced pressure at -0.07Mpa and 60°C until the concentration of solids in the concentrated liquid is 35%.

[0041] Spread the summer fresh leaves of the tea tree variety Bixiangzao with one bud and two leaves in an environment with a relative humidity of 80% and an ambient temperature of 25°C, with a thickness of 2-3cm. During this period, turn it twice until the tender stems are broken and the leaves are broken. The water content is 66%; the fresh tea leaves after being spread out are killed by a tea roller...

Embodiment 2

[0045] The autumn one-bud three-leaf tea fresh leaves of the tea tree variety Xiangfeicui are selected as raw materials.

[0046] Preparation of pineapple juice concentrate: Peel fresh pineapple, mash it with a tissue masher, then add pure water to the mashed pineapple according to the ratio of 1g pineapple to 1g purified water, mix well, and centrifuge at a speed of 16000 Centrifuge in a high-speed centrifuge at rpm, take the clarified liquid, and concentrate under reduced pressure at -0.05Mpa and 55°C until the concentration of solids in the concentrated liquid is 40%.

[0047] Spread the fresh leaves of the autumn one-bud three-leaf tea of the tea tree variety Xiangfeicui in an environment with a relative humidity of 75% and an ambient temperature of 20°C, with a thickness of 2-3cm. The water content is 68%; the fresh tea leaves after being spread out are killed by a tea roller fixing machine at an inlet temperature of 130°C and an outlet temperature of 90°C for 1min, and...

Embodiment 3

[0052] The autumn one-bud and two-leaf fresh leaves of the tea tree variety Fuding Dabai are selected as raw materials.

[0053] Preparation of pineapple juice concentrate: Peel fresh pineapple, mash it with a tissue masher, then add pure water to the mashed pineapple according to the ratio of 1g pineapple to 3g purified water, mix well, and centrifuge at a speed of 17000 Centrifuge in a high-speed centrifuge at rpm, take the clear liquid, and concentrate it under reduced pressure at -0.09Mpa and 65°C until the concentration of solids in the concentrated liquid is 30%.

[0054] Put the autumn one-bud and two-leaf fresh leaves of the tea tree variety Fuding Dabai tea in an environment with a relative humidity of 85% and an ambient temperature of 30°C, with a thickness of 2-3cm. Turn it over once during the period, until the tender stems are broken and continuously, The water content of the leaves is 64%; the fresh tea leaves after being spread out are killed by a tea roller fix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com