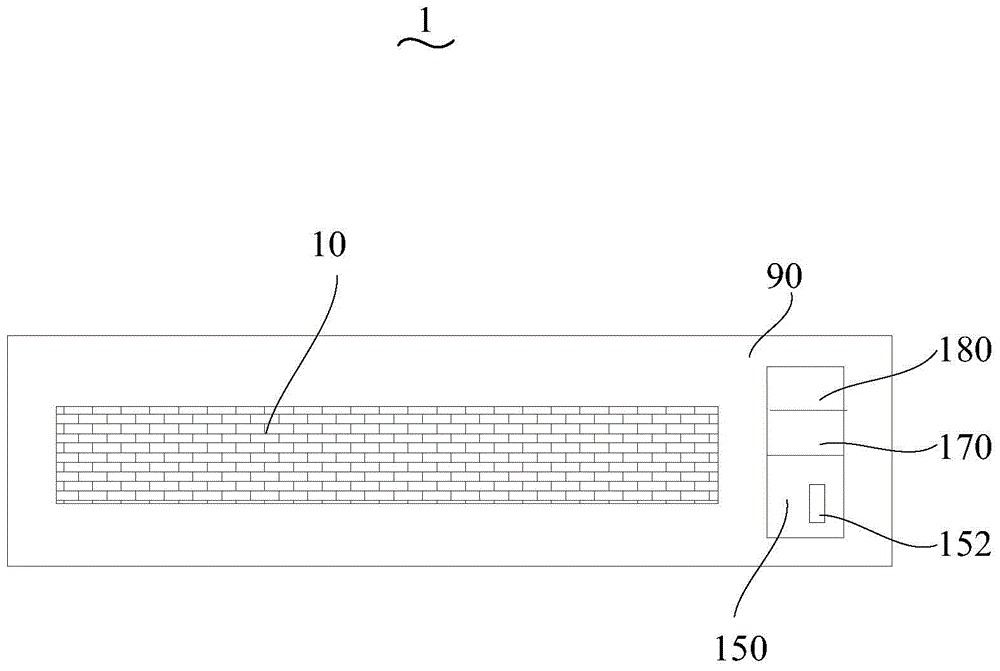

waist support

A technology of waist protection and bus bar is applied to waist protection. It can solve the problems of life-threatening, high power supply voltage and high risk of metal heating wire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

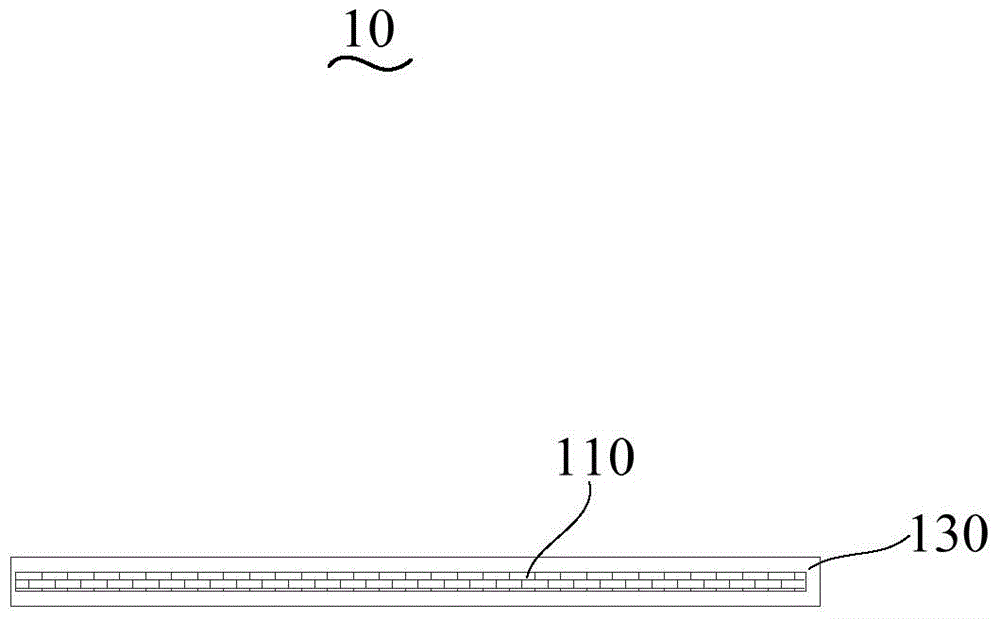

[0109] The preparation method of the above-mentioned heating film 210 is relatively simple, saving time and material cost. At the same time, the electrode layer is prepared by using metal foil, which has good conductivity and is beneficial to control the uniformity of the temperature of the heating film.

[0110] Preferably, the thickness of the first adhesive layer 213 and the second adhesive layer 217 is 25-75 μm.

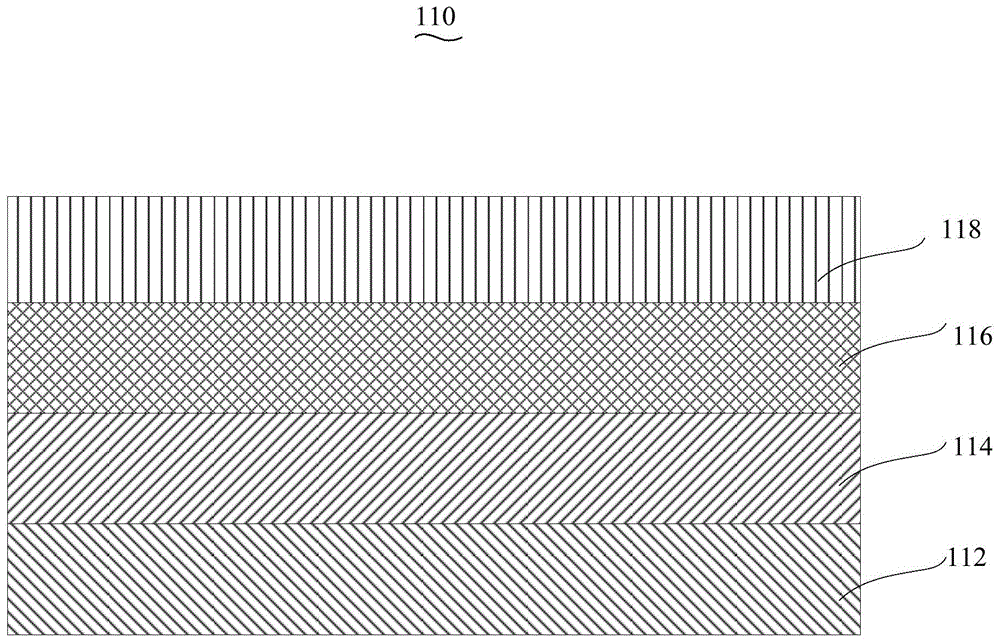

[0111] see Figure 6 , the structure of the waist support in another embodiment is substantially the same as that of the waist support 1, the difference is that in the illustrated embodiment, the heating film 410 of the waist support includes a first insulating layer 412, a conductive layer 414, and an electrode stacked in sequence. layer 416 , a second adhesive layer 417 and a second insulating layer 418 . The second insulating layer 418 is bonded to the electrode layer 416 through the second insulating layer 418 . Preferably, the material of the second adhesi...

Embodiment 1

[0128] Please also see Figure 4 and Figure 5 , single-layer graphene is used as the conductive layer of the heating film, and the electrode layer is printed with silver paste.

[0129] 1. Transfer a layer of graphene on the PET (first insulating layer) with an area of 150mm×150mm and a thickness of 125μm. The graphene has been doped and the square resistance is 250Ω / □;

[0130] 2. Use screen printing equipment to print the silver paste electrode pattern on the transferred graphene, the shape of the pattern is as follows: Figure 4 As shown, the distance between the positive inner electrode and the negative inner electrode is 6mm, the length of the positive inner electrode and the negative inner electrode is 108mm, and the width is 1mm, a total of 15, the width of the positive bus bar and the negative bus bar is 8mm, and the thickness of the silver paste is 25μm;

[0131] 3. Bake the printed electrode layer in an oven to solidify the silver paste. The baking temperature i...

Embodiment 2

[0142] In this embodiment, two layers of graphene are used as the conductive layer of the heating film, and the electrode layer is printed with silver paste.

[0143] 1. Transfer two layers of graphene as the conductive layer on the PET (first insulating layer) with an area of 120mm×120mm and a thickness of 125μm. The graphene has been doped and the square resistance is 120Ω / □;

[0144] 2. Use screen printing equipment to print the silver paste electrode layer on the transferred conductive layer, and the pattern shape is as follows: Figure 10 As shown, the outer diameter of the bus bar is 96mm, the inner electrode spacing is 6mm, the width is 1mm, the width of the bus bar is 8mm, and the thickness of the silver paste is 25μm;

[0145] 3. Bake the printed electrode pattern in an oven to solidify the silver paste. The baking temperature is 130°C for 40 minutes.

[0146] In this case, connect the lead wires to the positive and negative poles of the 5V power supply respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com