Novel gel thin-film capacitive sensor for measuring occlusal force of single pair of teeth and method

A technology of thin film capacitance and bite force, which is applied in the directions of sensors, muscle strength testing, diagnostic recording/measurement, etc., can solve problems such as difficult to ensure thorough disinfection, opacity, low bite force value, etc., and achieve good repeatable measurement accuracy, good biological Compatibility, easy processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

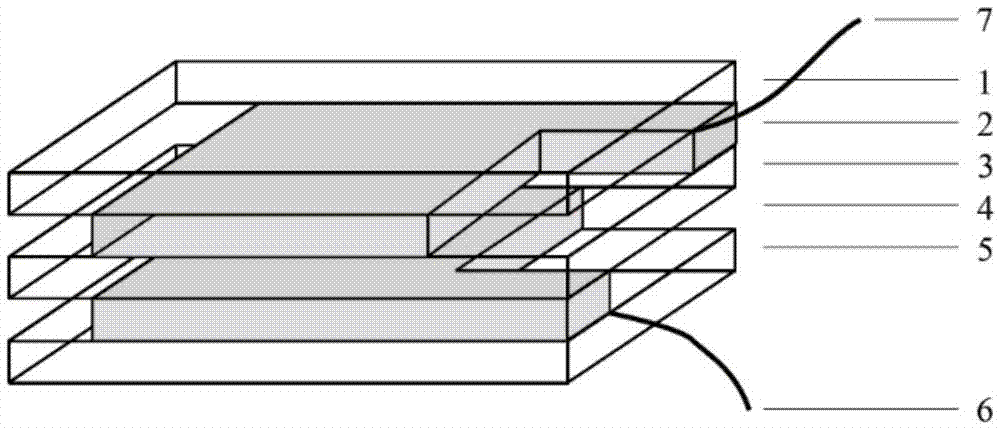

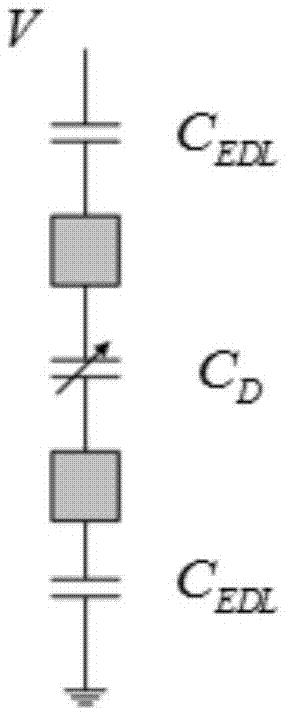

[0018] Such as figure 1 Shown, a kind of novel gel thin film capacitive sensor of the present invention measures the bite force of a single pair of teeth, is a kind of new soft, thin and transparent gel made real-time measurement thin film capacitive sensor of the bite force of a single pair of teeth, comprising The insulating medium 3, the upper layer of the insulating medium 3 is evenly bonded with the upper ion gel 2, the lower layer of the insulating medium 3 is uniformly bonded with the lower ion gel 4, and the upper ion gel 2, the insulating medium 3 and the lower ion gel 4 are formed For capacitors, in order to avoid the influence of external parasitic capacitance, a layer of upper insulating medium 1 is evenly pasted on the upper surface of the upper ion gel 2, and a layer of lower insulating medium 5 is evenly pasted on the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com