Three-metal reforming catalyst, preparation method and application

A technology for reforming catalysts and catalysts, applied in chemical instruments and methods, physical/chemical process catalysts, naphtha catalytic reforming, etc. Poor problems, achieve good industrial application prospects, reduce production costs, and good catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0052] Preparation example 1 of this carrier is to use HP dry rubber powder as raw material to prepare strip-shaped γ-Al 2 o 3 carrier

[0053] Get 500 grams of HP dry rubber powder (produced by Nanjing Catalyst Factory) and dry mix evenly with 14 grams of Tianqing powder, use 360 milliliters of deionized water, 12 milliliters of concentrations are 68 weight percent nitric acid (AR grade), 14 milliliters of concentrations are 32 weight percent % of acetic acid (AR grade), 15 grams of citric acid (AR grade) mixed solution, added to the HP dry rubber powder mixed with Tianqing powder, wet mixed, rolled, and then extruded with a cylindrical orifice plate with a diameter of Φ1.6mm Molding, curing at 30-60°C for 16 hours, drying at 120°C for 8 hours, cutting to a length of 3-8mm, and roasting at 630°C for 6 hours to obtain strip-shaped γ-Al 2 o 3 Carrier (referred to as HP-γ-Al 2 o 3 ).

preparation example 2

[0055] Prepare the carrier according to the method of carrier preparation example 1, the difference is that the raw material used is SB dry rubber powder (produced by German Condea company), and the strip-shaped γ-Al 2 o 3 Carrier (referred to as SB-γ-Al 2 o 3 ).

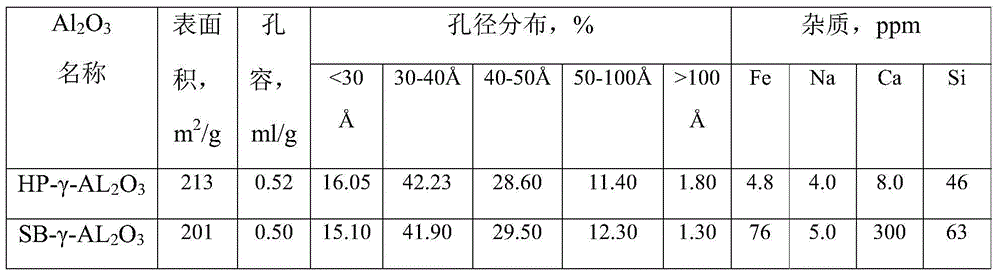

[0056] Wherein, the analytical data of the alumina carriers of carrier preparation example 1 and carrier preparation example 2 are shown in Table 1.

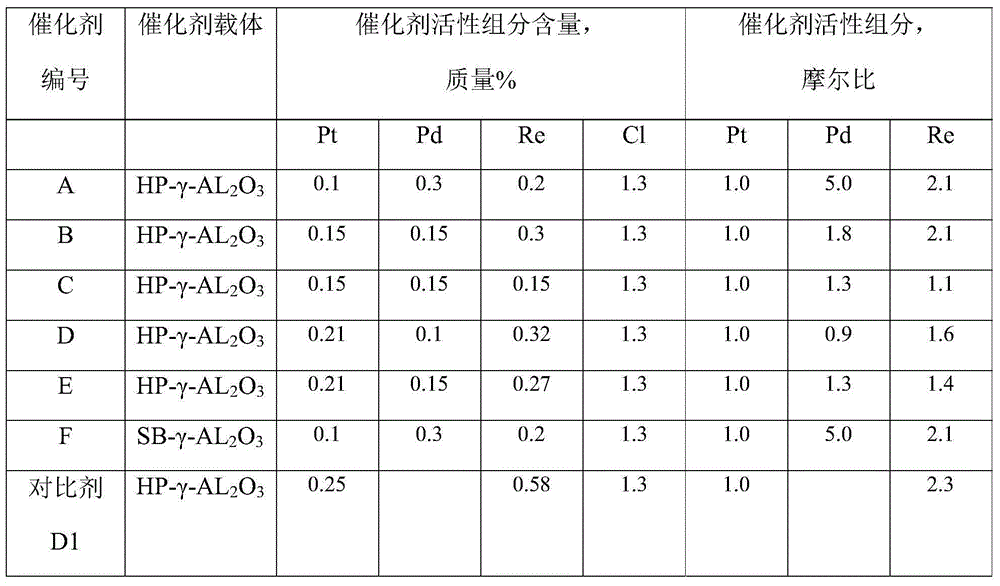

[0057] Catalyst preparation example 1

[0058] Be that 0.0075 gram Pt / ml chloroplatinic acid solution 13.4 milliliters, solid palladium chloride 0.504 gram, concentration be 0.0165 gram Re / milliliter perrhenic acid solution 12.2 milliliters, 1:1 (HCl:H at concentration 2 (volume ratio of O) concentration of dilute hydrochloric acid 8.5 milliliters, 140 milliliters of deionized water preparations in the solution to be impregnated, drop into the gamma-Al that 100 gram embodiment 1 prepares 2 o 3 The carrier (volume ratio of liquid to solid is 1.2:1), after impreg...

preparation example 2-5

[0060] Catalysts are prepared according to the method of catalyst preparation example 1, the difference is that different predetermined amounts of chloroplatinic acid, palladium chloride, perrhenic acid and the same amount of hydrochloric acid, deionized water are used to prepare impregnation solutions to prepare different Pt, Pd, Re Catalyst B, C, D, E of the molar ratio of content, composition sees Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com