The preparation method of orr catalyst

A catalyst and metal-organic framework technology, applied in the field of ORR catalyst preparation, can solve problems such as unsatisfactory results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The technical scheme of the preparation method of the ORR catalyst of the present invention is as follows, comprising the following steps:

[0036] 1) Dissolve the cobalt salt and 2-(p-N-imidazolyl)phenyl-1H-4,5-imidazoledicarboxylic acid ligand in water and acetonitrile solvent, and add acid to adjust the pH value of the solution after ultrasonic and stirring 2 to 4, and then hydrothermal reaction occurs at a constant temperature of 140 to 155°C for 48 to 96 hours; after cooling to room temperature, the obtained product is washed in turn and dried naturally to form a black-green transparent cobalt-containing multi-nitrogen metal organic compound. Framework material precursor (chemical formula: [Co(p-IPhHIDC)]n);

[0037] 2) The precursor material [Co(p-IPhHIDC)] prepared in step 1) n , after being thoroughly ground, ultrasonically dispersed in chloroplatinic acid (H 2 PtCl 6 ·6H 2 O) in the ethylene glycol solution, this mixed solution is placed in the microwave sy...

Embodiment 1

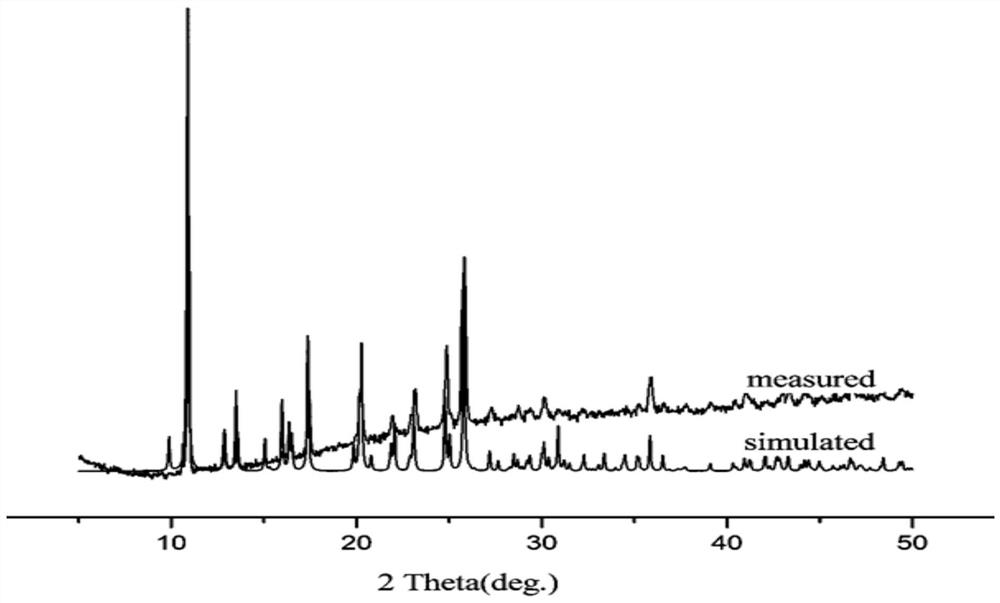

[0044] 1. 0.05mmol, 11.9mg of CoCl 2 ·6H 2 O and 0.03 mmol, 8.9 mg of 2-(p-N-imidazolyl)phenyl-1H-4,5-imidazoledicarboxylic acid ligand (p-IPhH3IDC) were dissolved in 2 mL of acetonitrile and 5 mL of water, mixed well and added concentrated HCl Adjust the pH to 2, and conduct a hydrothermal reaction at 150°C for 96 hours; after the reaction, the product obtained is centrifuged, washed three times with acetone, washed three times with water, and dried naturally at room temperature to obtain a black-green transparent cobalt-containing multi-nitrogen metal-organic framework Material. figure 1 Shown is the XRD pattern of the resulting product.

[0045] 2. After the material obtained in step 1 and the ethylene glycol solution of chloroplatinic acid are in a molar ratio of 1:0.02 ultrasonically dispersed, in N 2 Place it in a microwave synthesizer at 113°C under protection, and react with 10s / 10s intermittent microwave for 16min to make H 2 PtCl 6 Restored to simple Pt; in orde...

Embodiment 2

[0051] 1. 0.05mmol, 11.9mg of CoCl 2 ·6H 2 O and 0.03 mmol, 8.9 mg of 2-(p-N-imidazolyl) phenyl-1H-4,5-imidazole dicarboxylic acid ligand (p-IPhH3IDC,) were dissolved in 2 mL of acetonitrile and 5 mL of water, mixed well and added to HCl was adjusted to pH 4, and hydrothermal reaction was carried out at 150°C for 96 hours; after the reaction, the product obtained was centrifuged, washed three times with acetone, and washed three times with water, and dried naturally at room temperature to obtain a black-green transparent cobalt-containing multi-nitrogen metal organic compound. Framework material (Co-MNMOF).

[0052] 2. After the precursor Co-MNMOF material and the ethylene glycol solution of chloroplatinic acid are dispersed uniformly by ultrasonic at a molar ratio of 1:0.05, the N 2 Place it in a microwave synthesizer at 113°C under protection, and react with 10s / 10s intermittent microwave for 16min to make H 2 PtCl 6 Restored to simple Pt; in order to prevent the metal (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com