Preparation method and application of alpha-MoC1-x loaded Pt-Cu bimetallic water gas shift catalyst

A technology for transforming catalysts and catalysts, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, and non-metallic elements. The effect of good stability and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

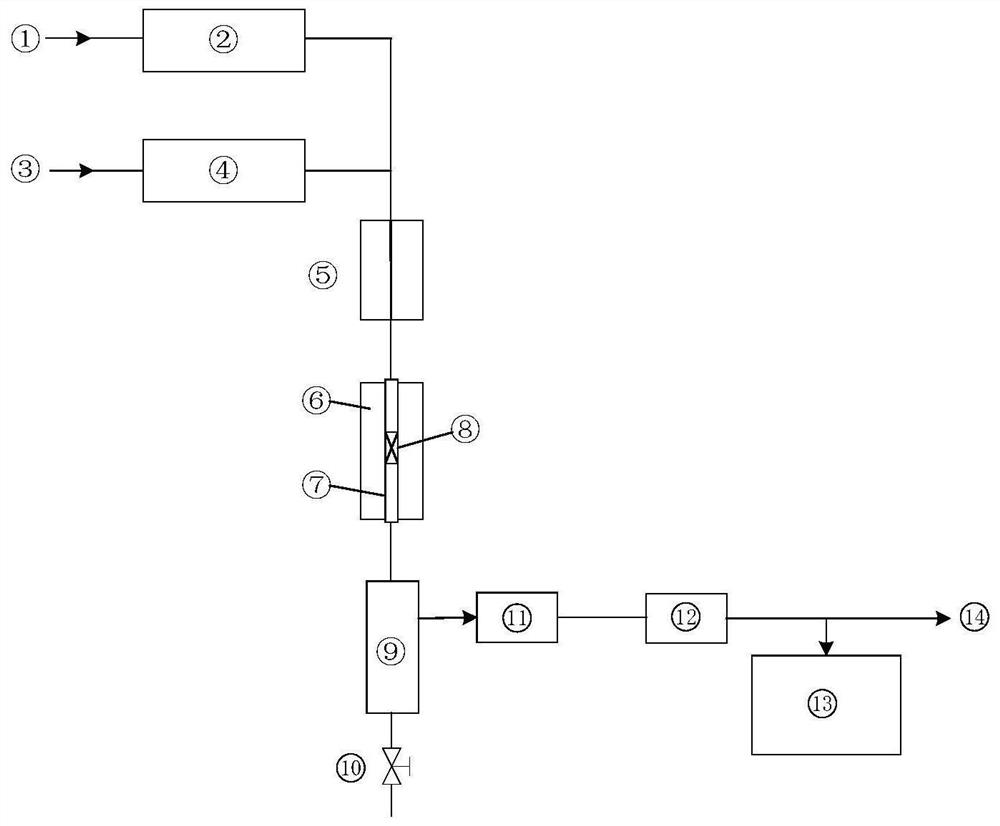

Method used

Image

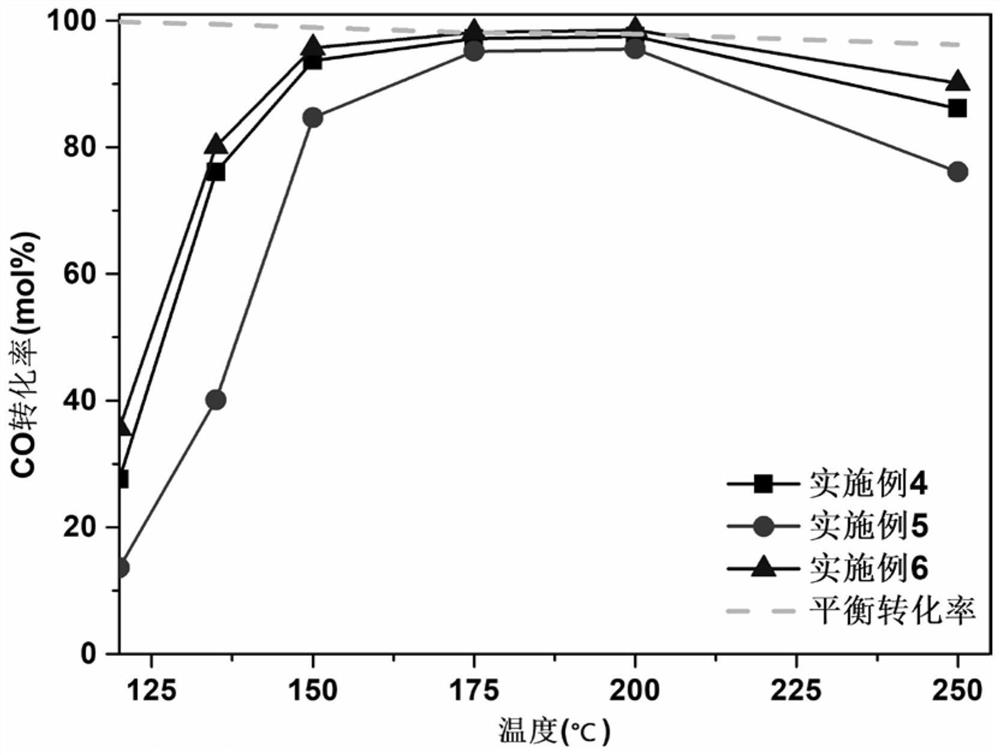

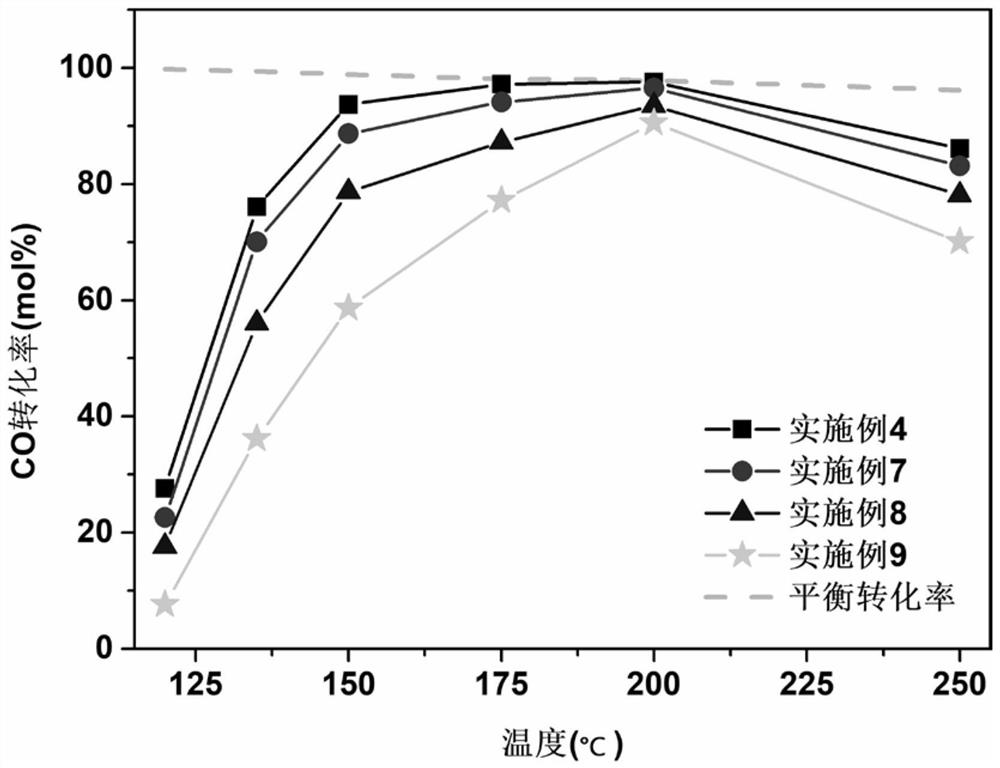

Examples

Embodiment 1

[0031] (1) 2.4718g ammonium molybdate was dissolved in 80mL deionized water to obtain an ammonium molybdate solution with a concentration of 0.025mol / L; then in the ammonium molybdate solution, dropwise the concentrated nitric acid of 65% mass concentration, nitric acid and molybdic acid The molar ratio of ammonium is 75:1, and then the acidified ammonium molybdate solution is transferred to a hydrothermal kettle for hydrothermal reaction at 180 °C for 24 h. After the hydrothermal reaction finishes, the hydrothermal kettle is lowered to room temperature, then the liquid in the hydrothermal kettle is transferred and filtered, and the obtained solids are washed with deionized water and dehydrated ethanol respectively and dried to obtain solid MoO 3 powder.

[0032] (2) with MoO obtained in step (1) 3 The solid powder is used as a carrier, and chloroplatinic acid with a platinum loading of 0.2 wt% and copper nitrate trihydrate with a copper loading of 5 wt% are respectively weig...

Embodiment 2

[0035] The process and conditions are the same as in Example 1, except that in step (2), the copper nitrate trihydrate is weighed according to the copper loading amount of 2.5wt%, and the obtained catalyst is recorded as 0.2Pt-2.5Cu / α-MoC 1-x .

Embodiment 3

[0037] The process and conditions are the same as in Example 1, except that in step (2), the copper nitrate trihydrate is weighed according to the copper loading amount of 7.5wt%, and the obtained catalyst is recorded as 0.2Pt-10Cu / α -MoC 1-x .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com