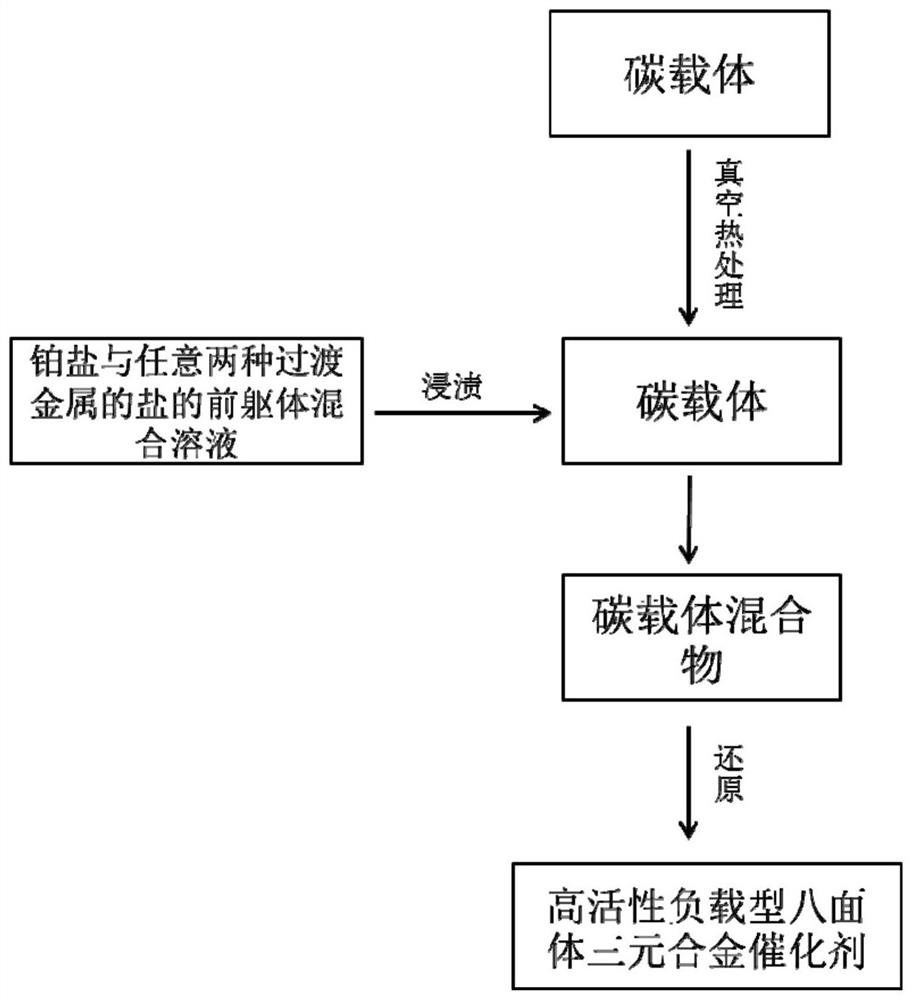

A kind of preparation method of highly active loaded octahedral ternary alloy catalyst

A ternary alloy, supported technology, applied in electrical components, structural parts, battery electrodes, etc., can solve the problem of low electrocatalyst activity, achieve the effect of convenient operation, improve catalyst activity, and reduce platinum content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

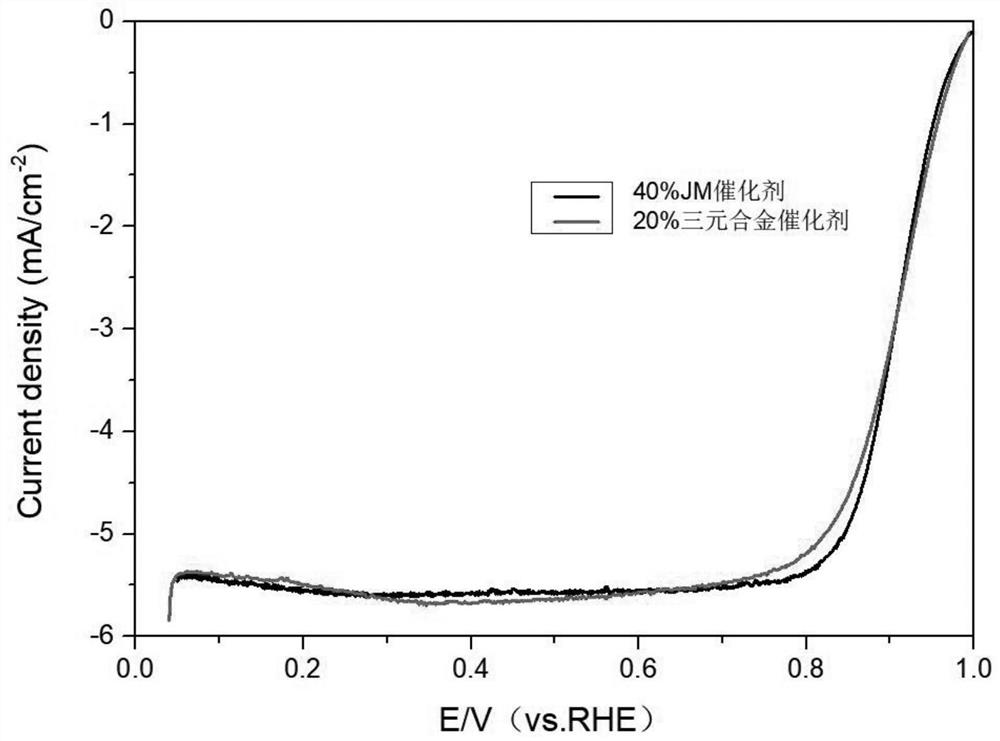

[0019] A method for preparing a highly active supported octahedral ternary alloy catalyst. The preparation method is as follows: S1. The carbon carrier is heated by a vacuum oven, and the vacuum degree of the vacuum oven is -0.1MPa. The heating method is as follows: first heat up, then heat up, the temperature of the heat preservation is 80 ℃ ~ 200 ℃, the time of the heat preservation is 6h ~ 15h; S2, using ultrasound to 1mmol of platinum salt (Pt(CH 3 COO) 2 ), 0.5mmol nickel salt (Ni(CH 3 COO) 2 ), 0.5mmol copper salt (Cu(CH 3 COO) 2 ) Dissolve in 40ml of organic solvent (chloroform) until all the solid matter is dissolved to obtain the precursor mixture solution; S3, under the conditions of a pressure of 0.03MPa and a temperature of 80°C, drop the precursor mixture solution obtained in step S2 dropwise Into the 0.8g carbon support (carbon nanotubes) obtained in step S1, fully impregnated to obtain a carbon support mixture; S4, continue to pass high-purity nitrogen to the carbo...

Embodiment 2

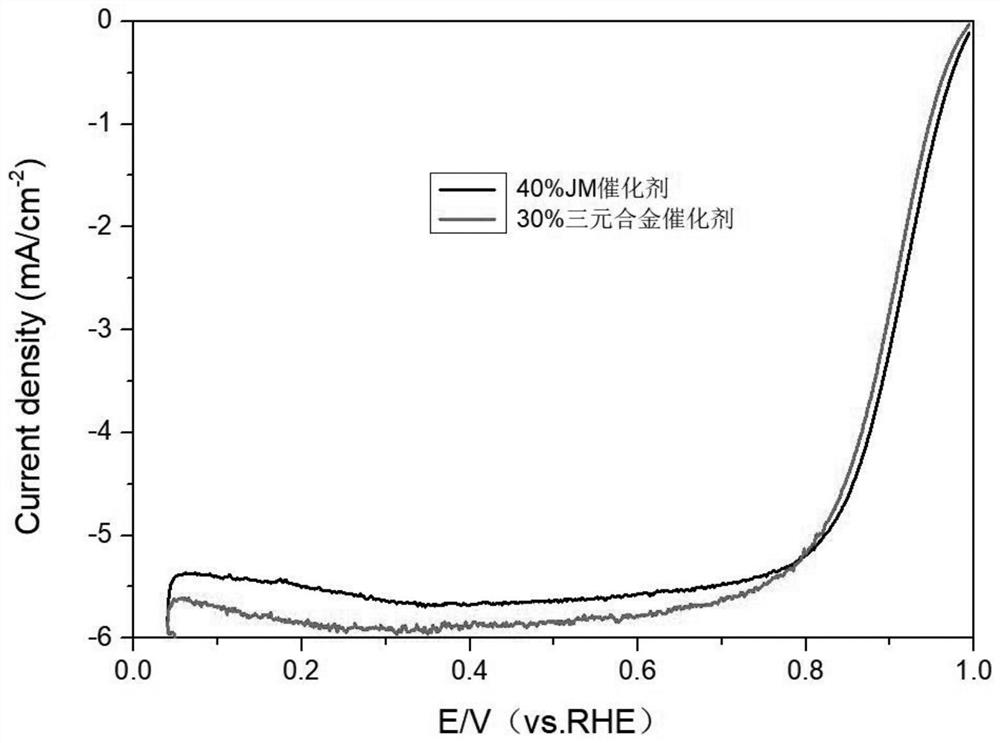

[0022] A method for preparing a highly active supported octahedral ternary alloy catalyst. The preparation method is as follows: S1. The carbon carrier is heated by a vacuum oven, and the vacuum degree of the vacuum oven is -0.1MPa. The heating method is as follows: first heat up, then heat up, the temperature of the heat preservation is 80 ℃ ~ 200 ℃, the time of the heat preservation is 6h ~ 15h; S2, the use of ultrasonic wave 2.5mmol platinum salt (H 2 PtCl 6 ·6H 2 O), 1.5mmol cobalt salt (CoCl 2 ·6H 2 O), 1.5mmol copper salt (Cu(CH 3 COO) 2 ) Dissolve in 30ml of organic solvent (acetone) until the solid matter is completely dissolved to obtain the precursor mixed solution; S3, under the conditions of a pressure of 0.06MPa and a temperature of 90°C, drop the precursor solution obtained in step S2 dropwise Pour into the 0.7g carbon carrier (XC-72R) obtained in step S1, and fully impregnate it to obtain a carbon carrier mixture; S4, continuously pass high-purity nitrogen to the c...

Embodiment 3

[0025] A method for preparing a highly active supported octahedral ternary alloy catalyst. The preparation method is as follows: S1. The carbon carrier is heated by a vacuum oven, and the vacuum degree of the vacuum oven is -0.1MPa. The heating method is: first heat up, then heat up, the temperature of the heat preservation is 80 ℃ ~ 200 ℃, the time of the heat preservation is 6h ~ 15h; S2, using ultrasonic waves to 3mmol of platinum salt (K 2 PtCl 6 ), 1.5mmol cobalt salt (Co(CH 3 COO) 2 ), 1.5mmol copper salt (Cu(NO 3 ) 2 ) Is dissolved in an organic solvent (a mixed solution of 20ml of acetone and 30ml of ethanol) until the solid matter is completely dissolved to obtain a precursor mixed solution; S3, under the conditions of a pressure of 0.08MPa and a temperature of 90°C, the precursor obtained in step S2 The liquid mixture solution was dripped dropwise into the 1.0g carbon carrier obtained in step S1, and fully impregnated to obtain a carbon carrier mixture; S4, the carbon c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com