Double-tank ultrasonic cleaner based on bidirectional ultrasonic radiation recombination transducer

A composite transducer and two-way radiation technology, which is applied in the field of ultrasonic cleaning, can solve problems such as low radiation power and radiation efficiency, sound energy waste, impedance mismatch, etc., achieve high radiation power and radiation efficiency, and improve radiation efficiency and power , improve the sound matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

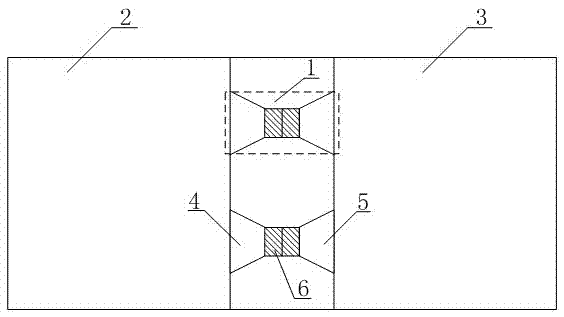

[0020] Such as figure 1 As shown, the present invention is a schematic structural diagram of a dual-slot ultrasonic cleaner based on a bidirectional ultrasonic radiation composite transducer, including a cleaning tank, wherein it also includes a bidirectional radiation transducer 1, and the cleaning tank includes a first cleaning tank 2 and a second cleaning tank. Two cleaning tanks 3, the two-way radiation transducer 1 includes a piezoelectric wafer 6, a front radiation metal cone block 4 and a rear radiation metal cone block 5; the radiation surface of the front radiation metal cone block 4, and the radiation surface of the rear radiation metal cone block 5 Bond with the first cleaning tank 2 and the second cleaning tank 3 respectively.

[0021] Wherein, the first cleaning tank 2 and the second cleaning tank 3 are rectangular tanks, and the first cleaning tank 2 and the second cleaning tank are all made of stainless steel; the radiation surface of the front radiation metal c...

Embodiment 2

[0023] On the basis of Example 1, the radiation power of the first cleaning tank 2 and the second cleaning tank 3 can be the same, and the front radiation metal cone block 4 and the rear radiation metal cone block 5 are all made of light metal materials such as aluminum alloy materials. Radius R of the small end of the conical horn of the bidirectional radiation transducer 1 1 = 19.5 mm, large end radius R 2 =27.5 mm, the thickness of each piezoelectric ceramic ring is L 01 = L 02 =5 mm, the inner and outer radii are R 01 = 7.5 mm, R 02 =19 mm. When the resonant frequency is 20 kHz, the length of the front and rear metal horns can be L 1 = L 2 =50 mm; when the resonant frequency is 30 kHz, the length of the front and rear metal horns can be L 1 = L 2 =32.5 mm; when the resonant frequency is 40 kHz, the length of the front and rear metal horns can be L 1 = L 2 =23.5mm.

Embodiment 3

[0025] On the basis of Example 1, the radiation power of the first cleaning tank 2 and the second cleaning tank 3 can be different, and the front radiation metal cone block 4 and the rear radiation metal cone block 5 are made of aluminum alloy material and stainless steel material respectively. Radius R of the small end of the conical horn of the bidirectional radiation transducer 1 1 = 19.5 mm, large end radius R 2 =27.5 mm, the thickness of each piezoelectric ceramic ring is L 01 = L 02 =5 mm, the inner and outer radii are R 01 = 7.5 mm, R 02 =19 mm. When the resonant frequency is 20 kHz, the lengths of the front and rear metal horns can be L respectively 1 = 50 mm, L 2 =43.5 mm; when the resonant frequency is 30 kHz, the lengths of the front and rear metal horns can be L 1 = 32.5 mm, L 2 =26 mm; when the resonant frequency is 40 kHz, the lengths of the front and rear metal horns can be L respectively 1 = 23.5 mm, L 2 =17 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com