Molding sand clearing device for cylinder cover inner cavity

A cleaning device and cylinder head technology, which is applied in the field of cylinder head processing and manufacturing, can solve the problems of high product defect rate, noise pollution, low sand falling rate, etc., and achieve the goal of reducing defective product rate, ensuring health and reducing noise pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below by means of specific embodiments:

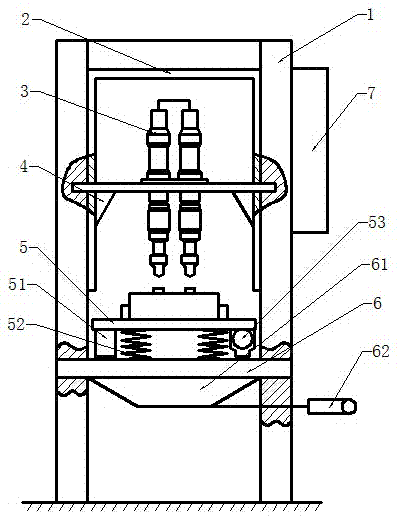

[0013] The reference signs in the drawings of the description include: frame 1, sponge sound-absorbing layer 2, impact hammer 3, support rod 4, vibration plate 5, balance weight 51, vibration spring 52, support plate 6, sand collecting bucket 61, gate plate 62. Control box 7.

[0014] The embodiment is basically as attached figure 1 Shown: a cylinder head cavity molding sand removal device, including a frame 1, a support mechanism, a hammer 3 and a silencer mechanism, the support mechanism includes a support plate 6, a mounting plate, and the support plate 6 is horizontally installed on the frame 1, the lower end of the support plate 6 is fixed with an inverted trapezoidal sand collecting bucket 61, and the lower end of the sand collecting bucket 61 is provided with a transverse flashboard 62. The upper end of the support plate 6 is fixed with a plurality of vibrating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com