A precision pulley bracket welding assembly machine

A pulley bracket and assembly machine technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of difficult control of weld scar height and weld scar uniformity, hindering efficiency improvement and quality stability, and scrap processing of workpieces. Achieve the effect of good surface quality, high production efficiency and precise trajectory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

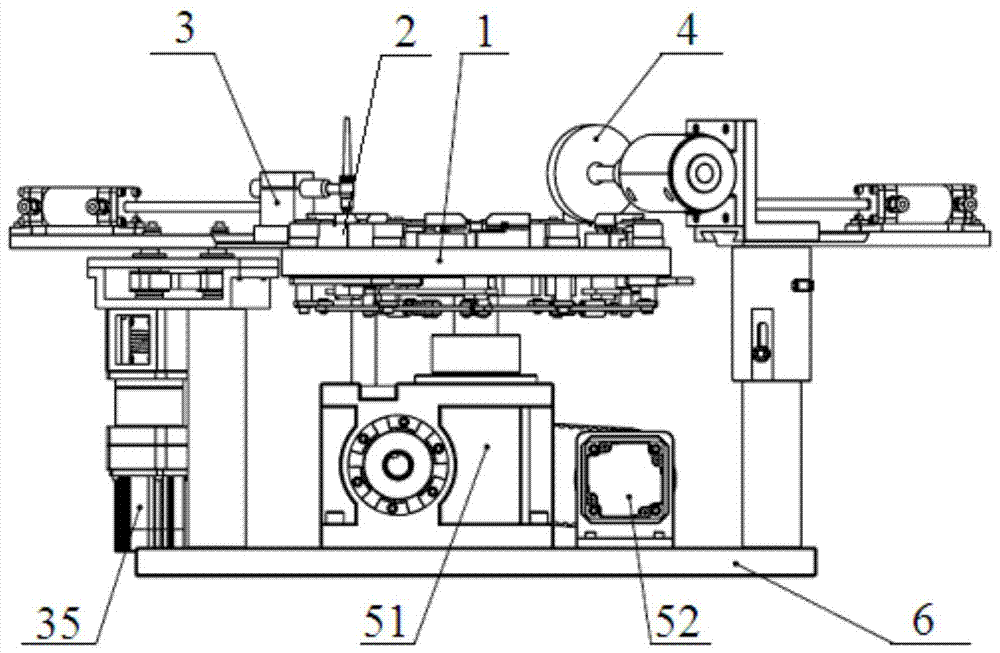

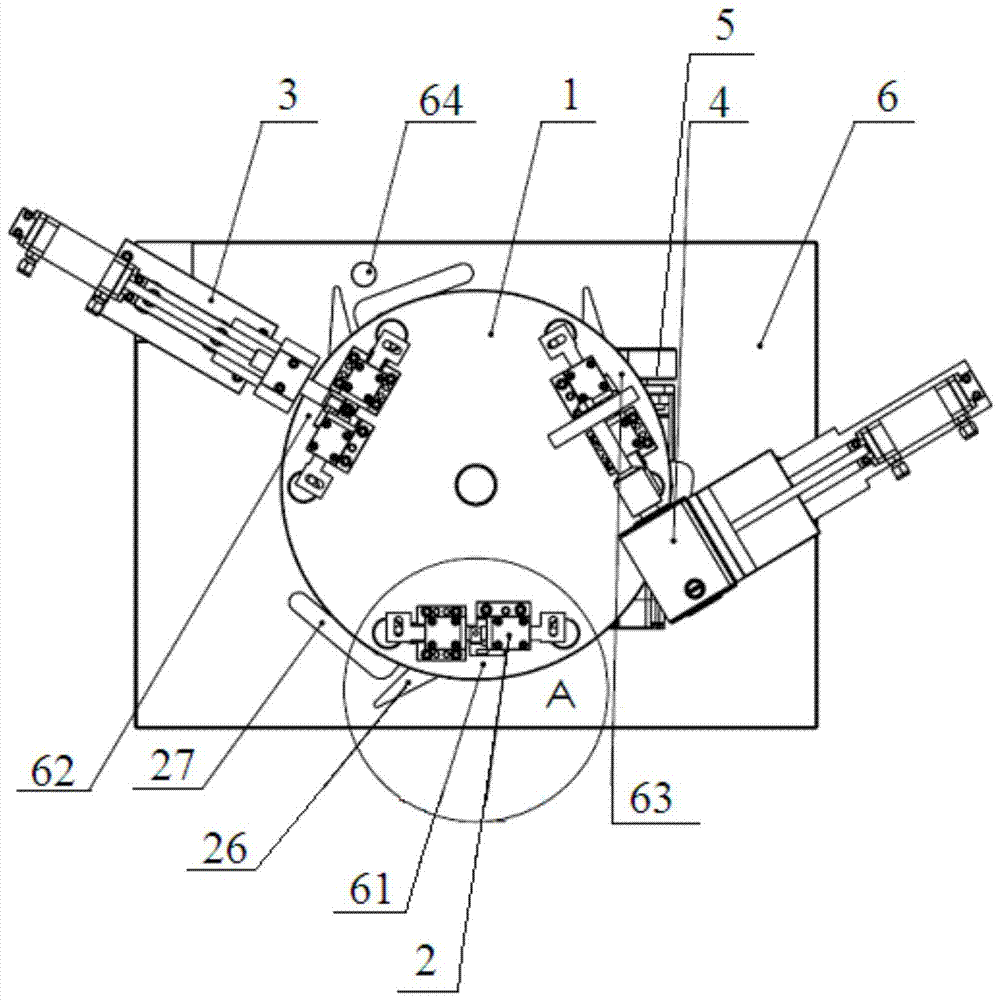

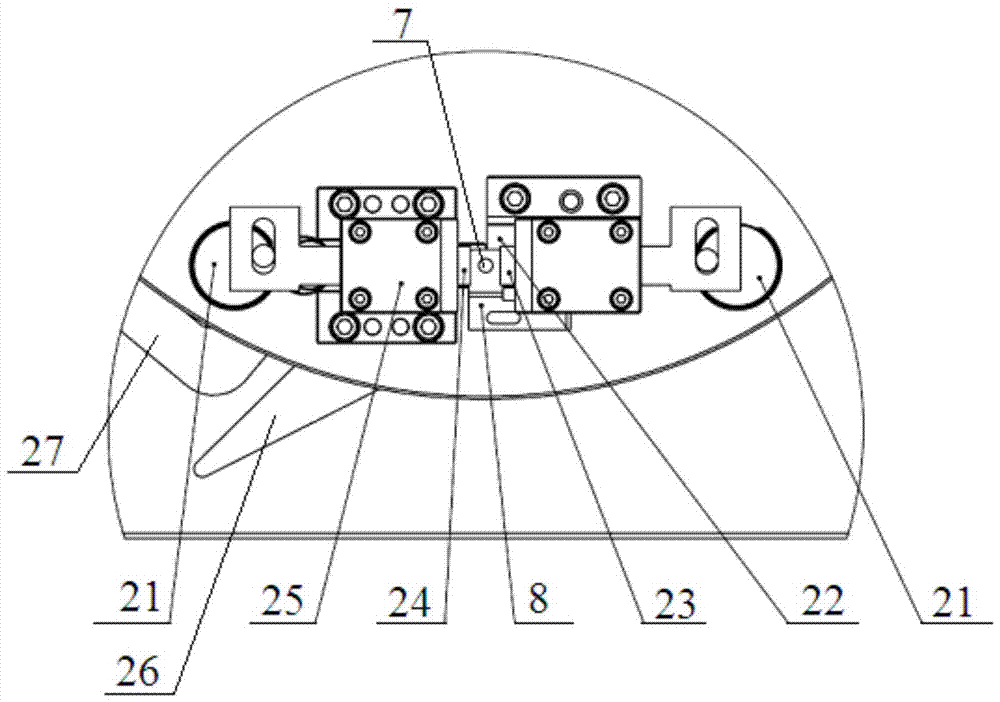

[0033] A precision pulley bracket welding assembly machine, such as figure 1 , figure 2 As shown, it includes a clamping table 1, a workpiece fixture assembly 2, an argon arc welding assembly 3, a grinding assembly 4, a workbench drive assembly 5 and a frame 6, and the frame 6 includes a loading and unloading station 61 and an argon arc welding station 62 and grinding station 63; the clamping workbench 1 is set on the frame 6, and simultaneously contacts with the loading and unloading station 61, the argon arc welding station 62 and the grinding station 63; the workbench drive assembly 5 includes a divider 51 and a splitter The divider servo motor 52, the divider servo motor 52 is fixed on the top of the frame 6, and the divider 51 is located below the clamping workbench 1, and is connected with the divider servo motor 52. The workpiece fixture assembly 2 is arranged on the clamping workbench 1, and is used to install and fix the pulley shaft 7 and the pulley bracket 8 to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com