Crane

A technology of cranes and counterweights, which is applied in the direction of cranes, etc., can solve the problems of complex conversion process and inability to move the position of counterweights, achieve huge economic benefits, improve equipment lifting capacity, and improve operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

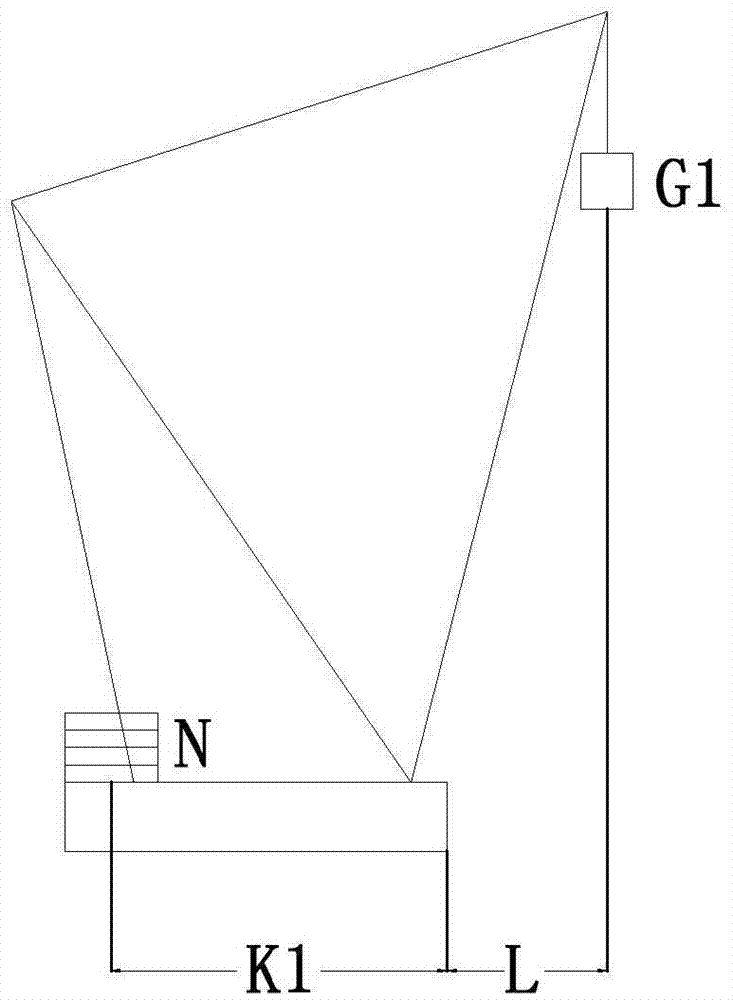

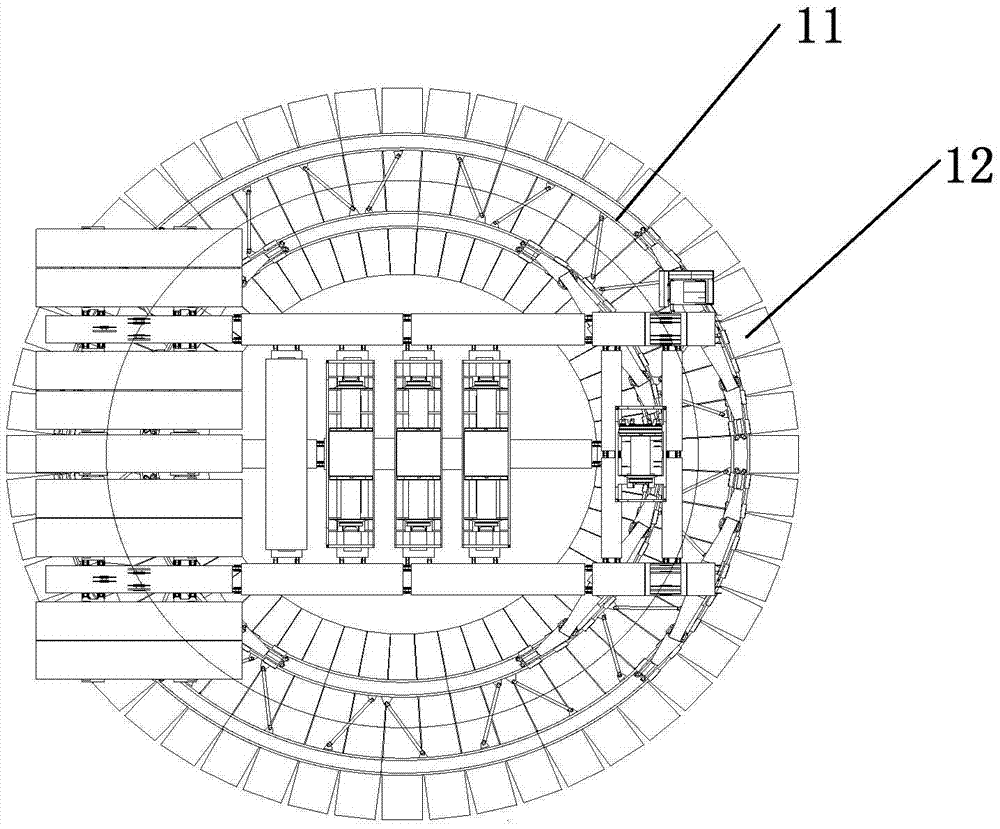

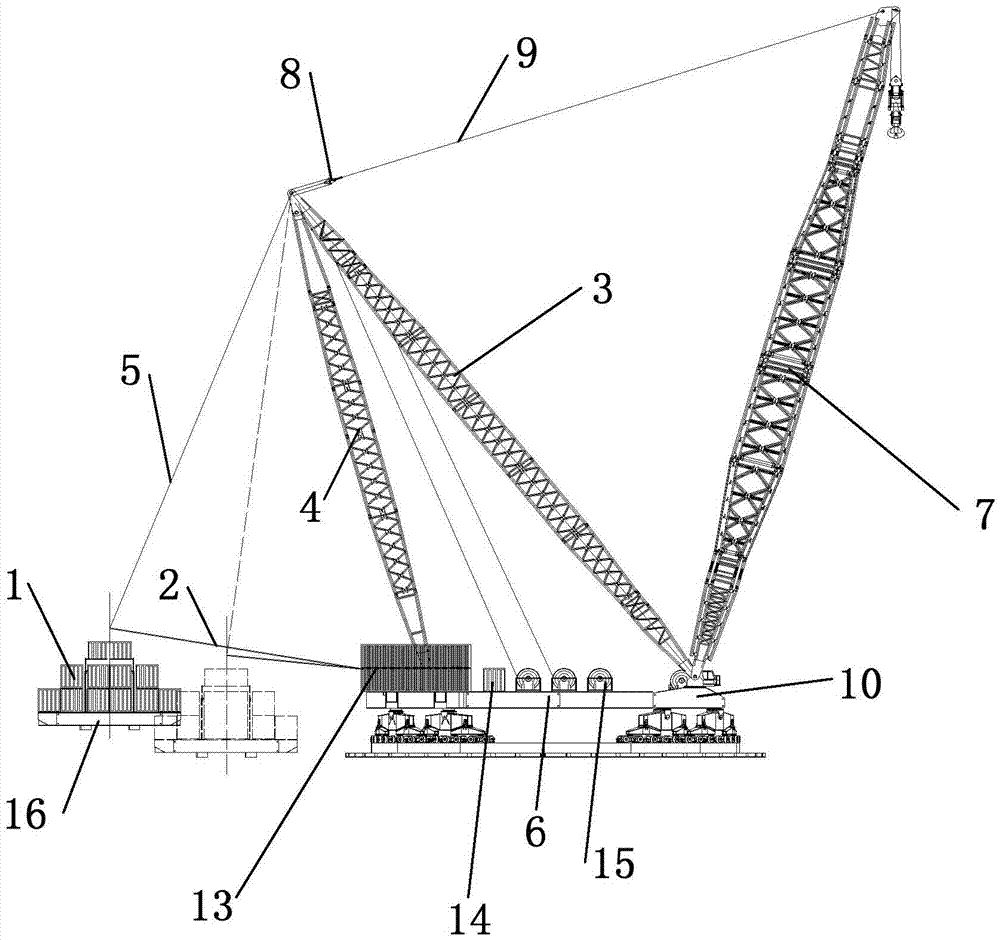

[0037] Combine below Figure 1 to Figure 5 The technical solution provided by the present invention is described in more detail.

[0038] Explanation of nouns or terms involved in this article.

[0039] A-type main boom: The main boom part at the front end of the lifting equipment is an "A"-type double truss arm structure.

[0040] Mast: The end is hinged with the platform, and the other end is connected with the A-type main boom mast and the counterweight through the pull plate (or pull rope, truss), which can change the working range of the boom and improve the lifting performance of the mast.

[0041] Mast bracket: one end is connected to the mast, and the other end is connected to the platform, which can provide tension for the mast or support the mast.

[0042] Luffing pulley block: The extension and contraction of the steel wire rope is controlled by the pulley block, and the pull plate pulls the A-type main arm to rotate along the lower hinge point to realize luffing....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com