Method for recycling recycled N,N'-dicyclohexylurea

A technology of dicyclohexylurea and cyclohexylamine, which is applied in chemical instruments and methods, preparation of amino compounds, preparation of organic compounds, etc., can solve the problems of high production cost, poor safety, low yield and the like, and achieves easy separation, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

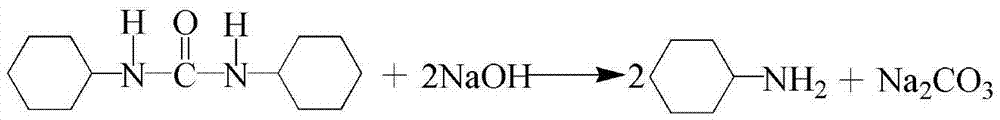

Method used

Image

Examples

Embodiment 1

[0018] Add 2000kg of N,N'-dicyclohexylurea and 800kg of sodium hydroxide to the reaction kettle, start stirring, raise the temperature to 230°C, and control the temperature at 230-240°C, and keep it warm for 6h. 1750kg of cyclohexylamine products were distilled, with a yield of 99.15% and a purity of 99.77%.

Embodiment 2

[0020] Add 2000kg of N,N'-dicyclohexylurea and 1000kg of sodium hydroxide to the reaction kettle, start stirring, raise the temperature to 270°C, and control the temperature at 270-280°C, and keep it warm for 5h. 1758kg of cyclohexylamine products were distilled, with a yield of 99.25% and a purity of 99.53%.

Embodiment 3

[0022] Add 2000kg of N,N'-dicyclohexylurea and 1200kg of sodium hydroxide to the reaction kettle, start stirring, raise the temperature to 340°C, and control the temperature at 340-350°C, and keep it warm for 3h. 1754kg of cyclohexylamine products were distilled, with a yield of 99.385% and a purity of 99.59%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com