Method for decomposing triazine ring residues to recover methylhydrazine

A technology of triazine ring and methylhydrazine, which is applied in the field of recovery and utilization of by-products of pharmaceutical intermediates, can solve problems such as difficult to handle, large amount of by-products, and low product yield, and achieve the effect of low cost and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

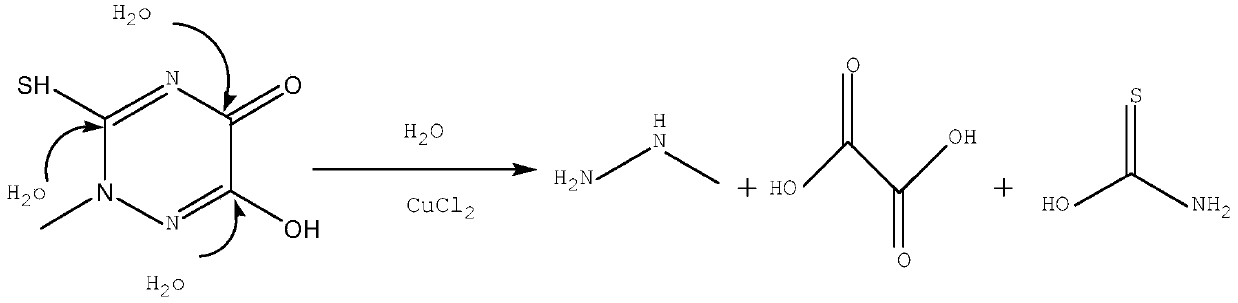

Method used

Image

Examples

Embodiment 1

[0020] Add 30g of triazine ring residue, 300g of water, and 2g of copper chloride to the reaction flask, start stirring, raise the temperature to 130°C and keep it warm for 2 hours, add 7.5g of caustic soda after extracting the distillate, and extract methylhydrazine after distillation of aqueous solution.

Embodiment 2

[0022] Add 30 g of triazine ring residue, 400 g of water, and 6 g of copper chloride to the reaction flask, start stirring, raise the temperature to 110° C. and keep it warm for 4 hours. aqueous solution.

Embodiment 3

[0024] Add 30 g of triazine ring residue, 900 g of water, and 1.5 g of copper sulfate to the reaction flask, start stirring, raise the temperature to 90° C. and keep it warm for 5 hours. aqueous solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com