Cladding method for inner wall of pipeline

A pipeline and cladding technology, applied in the coating, metal material coating process, etc., can solve the problems of natural gas and crude oil leakage, unsatisfactory effect, economic loss, etc., achieve high yield, avoid sharp temperature rise, improve quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

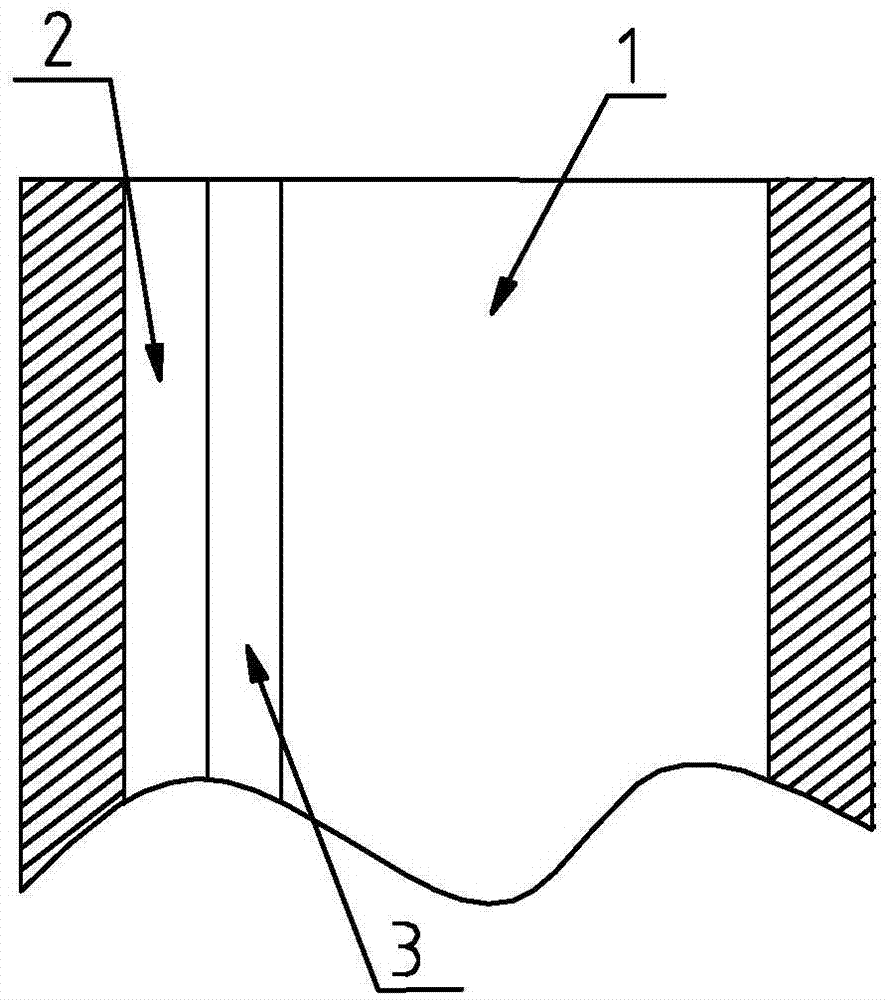

[0044] A method for cladding the inner wall of a pipeline, comprising the following steps:

[0045] (1) Pretreat the inner wall of the pipeline 1 to be processed, remove burrs and rust on the inner wall surface, and expose the metallic luster;

[0046] (2) The pipeline 1 to be processed is fixed on the tooling, the laser head is placed inside the pipeline 1 to be processed, and the laser head feeds in the direction of the main axis of the pipeline 1 to be processed, and the laser head is provided with a smoke removal The device and powder feeding device can absorb the smoke generated during the cladding process in time;

[0047] (3) Adopt synchronous powder feeding mode, the laser head moves from one end of the pipeline to be processed 1 to the other end along the main axis direction of the pipeline to be processed 1, and completes a feed movement;

[0048] (4) The laser head resets along the main axis direction of the pipeline 1 to be processed, and performs the next feed mo...

Embodiment 2

[0060] The same part of this embodiment and Embodiment 1 will not be described again, the difference is:

[0061] The alloy powder includes the following formula components: C: 0.9-1.2 parts, W: 4.0-4.2 parts, Ni: 1.0-3.0 parts, Co: 60.8-66.6 parts, Fe: 0.3-1.0 parts, Cr: 26.1-28.5 parts Parts, Si: 1.1-1.3 parts.

[0062] The length of the pipeline 1 to be processed is 3m, the cross section of the pipeline 1 to be processed is a square, and the cladding method is as follows:

[0063] (1) During a feed movement of the laser head along the main axis direction of the pipeline to be processed 1, the laser head is clad from one end of the inner wall of the pipeline to be processed 1 to the other end to obtain the Nth cladding strip 2, Its unilateral thickness is 1.6mm;

[0064] (2) The laser head is reset along the main axis direction of the pipeline 1 to be processed, and cladding the side of the Nth cladding strip 2 from one end of the pipeline 1 to be processed to the other en...

Embodiment 3

[0071] The same part of this embodiment and Embodiment 1 will not be described again, the difference is:

[0072] The alloy powder includes the following formula components: C: 1.2 parts, W: 4.2 parts, Ni: 3.0 parts, Co: 66.6 parts, Fe: 1.0 parts, Cr: 28.5 parts, Si: 1.3 parts.

[0073] The length of the pipeline 1 to be processed is 2.5m, and the cross section of the pipeline 1 to be processed is a regular hexagon, and the cladding method is as follows:

[0074] (1) During a feed movement of the laser head along the main axis direction of the pipeline to be processed 1, the laser head is clad from one end of the inner wall of the pipeline to be processed 1 to the other end to obtain the Nth cladding strip 2, Its unilateral thickness is 2mm;

[0075] (2) The laser head is reset along the main axis direction of the pipeline 1 to be processed, and cladding the side of the Nth cladding strip 2 from one end of the pipeline 1 to be processed to the other end, forming the N+th 1 c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com