Lyocell knitted-fabric-like fabric and processing method thereof

A processing method and imitating knitting technology, applied in textiles, fabrics, textiles and papermaking, etc., can solve the problems of increased weaving defects of fabrics, reduced weaving efficiency, increased process difficulty, etc., and achieve the effect of dimensional stability and not easy to curl.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

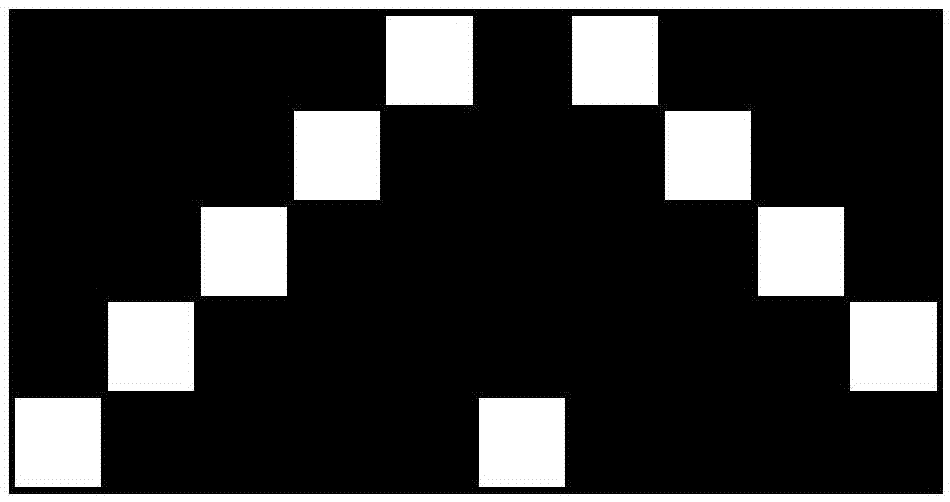

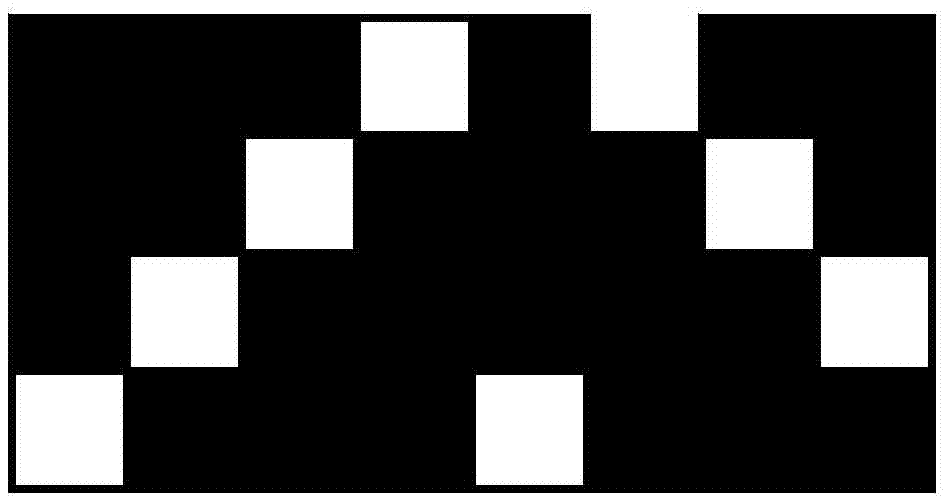

Image

Examples

Embodiment 1

[0026] Specifications: 106' / Tencel 32s*Cotton 21s / 133*60, the warp is made of Tencel ring-spun yarn, and the Tencel fibers are processed to make the cloth surface fine and tiny fluff. The weft yarn is ring-spun cotton yarn with a twist coefficient of 340, and the fabric weave is 4 / 1 warp surface mountain-shaped twill weave.

[0027] Its production method includes the following steps: warp warping → sizing → wearing brown reed → wearing warp stopper → weaving → gray fabric singeing - cold stacking - whitening tentering - sanding - printing - steam washing - loose washing - Soft hold - pre-shrunk.

[0028] Sizing process: 50kg of phosphate starch, 75kg of CD-DF868 high-performance starch, 5kg of propylene and 3kg of wax flakes.

[0029] The singeing process adopts one front and one reverse, the speed of the vehicle is 120m / min, the fire is extinguished by rolling enzyme, the amylase is 6g / L, the cloth is dropped by the car, and the pile is 6h.

[0030] The cold stack process a...

Embodiment 2

[0036] Specifications: 106' / Tencel 21s*cotton 16s / 108*50, the warp is made of Tencel ring-spun yarn, and the Tencel fibers are processed to make the cloth surface fine and tiny fluff. The weft yarn is ring-spun cotton yarn with a twist coefficient of 340, and the fabric weave is a 3 / 1 warp surface mountain-shaped twill weave.

[0037] Its production method includes the following steps: warp warping → sizing → wearing brown reed → wearing warp stopper → weaving → gray fabric singeing - cold stacking - whitening tentering - sanding - printing - steam washing - loose washing - Soft hold - pre-shrunk.

[0038] Sizing process: 50kg of phosphate starch, 75kg of CD-DF868 high-performance starch, 5kg of propylene and 3kg of wax flakes.

[0039] The singeing process adopts one front and one reverse, the speed of the vehicle is 120m / min, the fire is extinguished by rolling enzyme, the amylase is 6g / L, the cloth is dropped by the car, and the pile is 6h.

[0040] The cold stack process...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Warp strength | aaaaa | aaaaa |

| Weft strength | aaaaa | aaaaa |

| Warp strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com