Film-coated metal sheet metal enclosure system and its construction method

A metal thin plate and film covering technology, which is applied to the roof covering layer, the roof using flat/curved panels, roofing, etc., can solve the problems of roof water leakage, roof damage, nail hole deformation, etc., to ensure construction quality, The construction method is simple and the effect of eliminating the hidden danger of water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

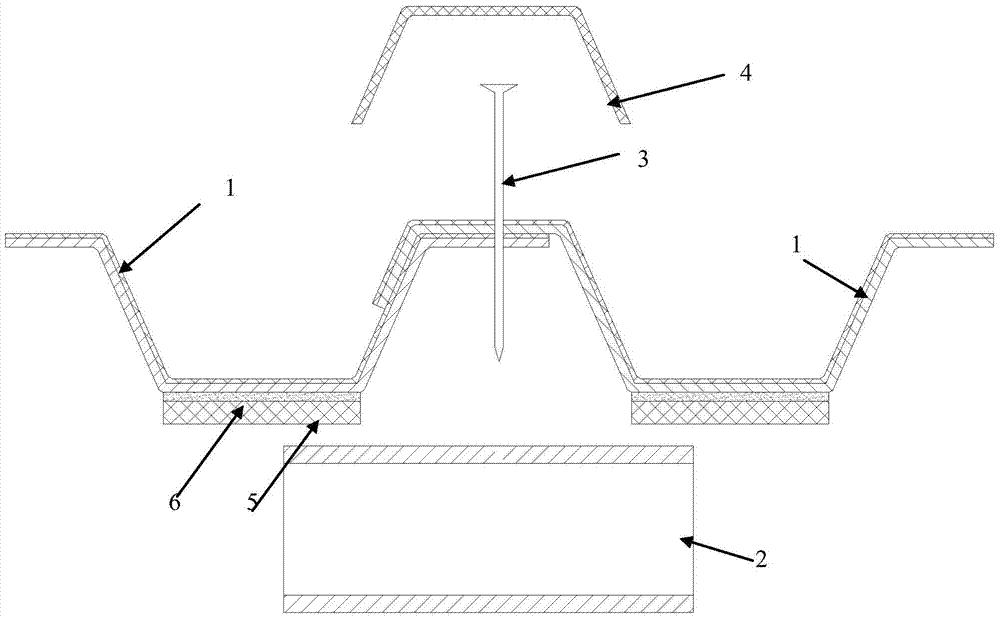

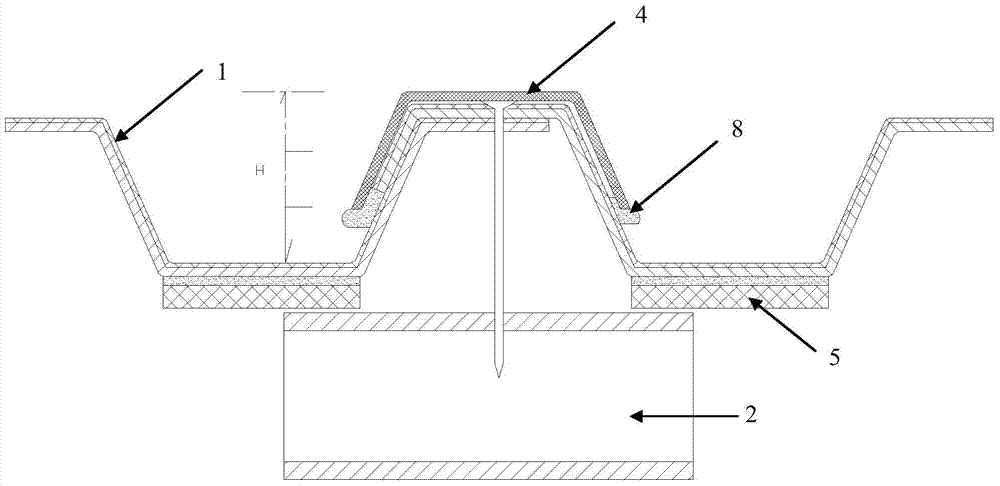

[0044] Such as figure 1 and figure 2 As shown, the metal enclosure system of the present invention includes at least two overlapping film-coated metal sheets 1, and the two film-coated metal sheets are overlapped at the edge; A support structure 2 is provided; a fixing nail 3 is nailed through the overlap of two layers of coated metal sheets so that the two layers of coated metal sheets are nailed to the support structure 2; a welding film is covered on the overlap of the two layers of coated metal sheets 4. The two sides of the welding film are welded on the two layers of film-coated metal sheets near the seam to form a welding seam 8 .

[0045] The above-mentioned welding refers to welding the welding film and the coating on the two-layer coated metal sheet, and ultrasonic welding commonly used in plastic welding can be used.

[0046] A foam heat insulation and noise reduction layer 5 is provided on the inner surface of the trough of the metal profiled sheet 1 . Wherein,...

Embodiment 2

[0059] The construction method of the film-coated metal sheet of the present invention, the described construction method is:

[0060] Lap two laminated metal sheet edges over a purlin or support structure;

[0061] Nails or screws are used to penetrate the two layers of film-coated metal sheets so that the two layers of film-coated metal sheets are nailed to the purlins or supporting structures;

[0062] Cover the lap joints with a welding film identical or similar to that of the coated sheet metal;

[0063] The sides of the welded film are welded to the film on the two laminated metal sheets.

[0064] Above-mentioned thin plate can be profiled thin plate, as figure 1 figure 2 The metal sheet shown is a profiled sheet, which has crests and troughs; the crests of the two coated metal sheets are overlapped, and the nails or screws are nailed through the two layers of coated metal sheets to make the two layers The crests of the film-coated metal sheets are nailed to the pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com