Deep refrigeration regulating valve with piston pressure self-sealing and positioning functions

A piston pressure, self-sealing technology, used in shaft seals, valve heating/cooling devices, lift valves, etc., can solve problems such as frequent replacement, short service life of cryogenic control valves, and instability of vertical pressure rods. , to achieve the effect of eliminating icing and bonding, reliable valve sealing, and improved safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

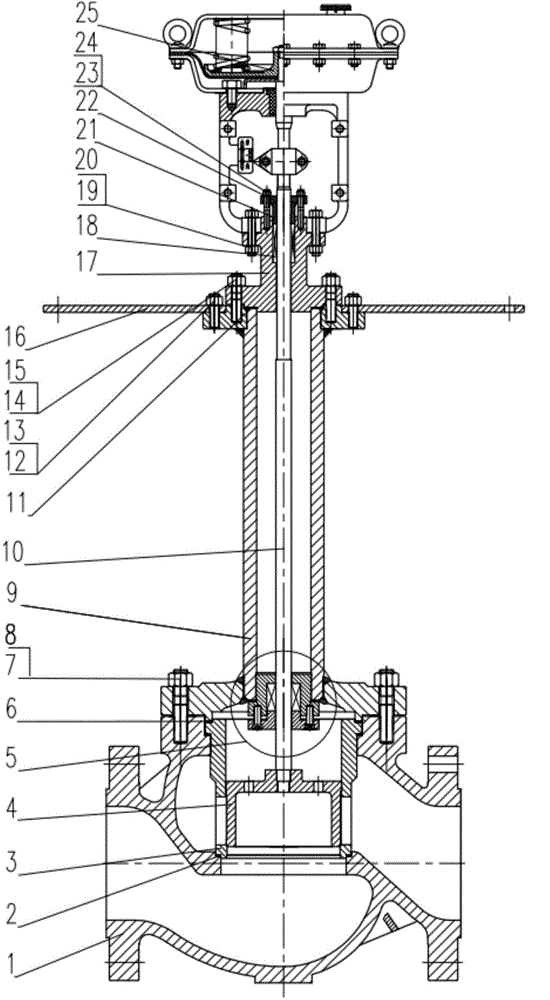

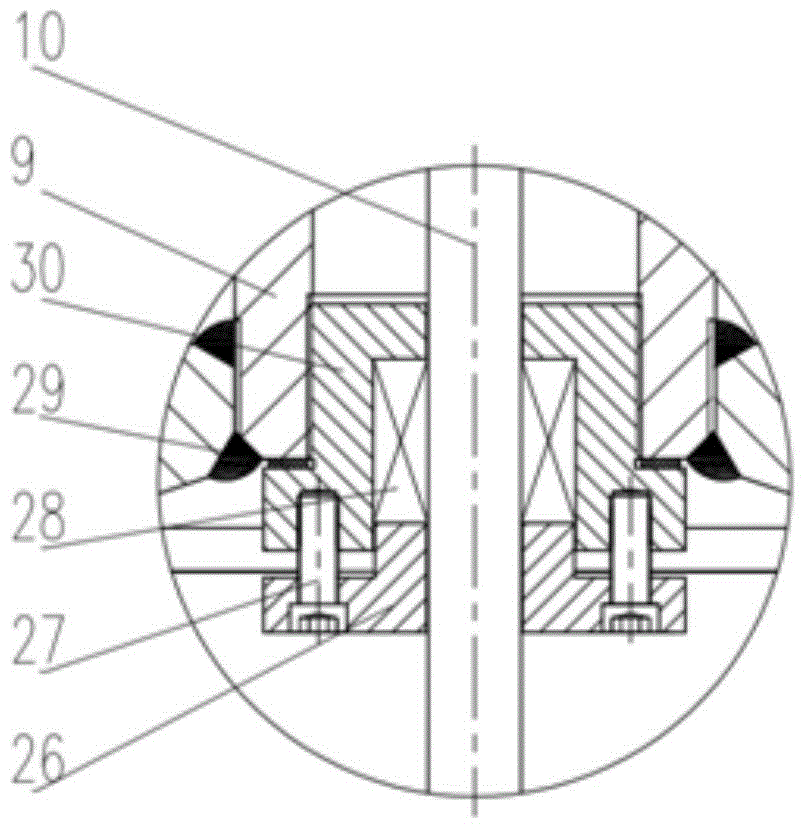

[0020] see figure 1 , a cryogenic control valve with piston pressure self-sealing and positioning. The valve body 1 is provided with a sleeve 3 and a metal wound gasket 2 therebetween. A valve plug 4 is arranged inside the sleeve, and the upper part of the valve plug is connected with the lower part of the valve stem 10 . The bottom of the extended bonnet 9 is provided with a piston pressure self-sealing and positioning assembly 5, which is connected with the internal thread at the lower end of the extended bonnet by its upper thread. The extended valve cover 9 arranged on the upper part of the valve body is fixed by bolts 7 and nuts 8 fasteners, and the sealing gasket 6 and the sleeve are compressed therebetween. An isolation drip pan 16 and an upper valve cover 17 are provided above the extended valve cover, which are respectively connected and fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com