Hypersonic speed super-combustion stamping engine real-time model and simulation method

A scramjet, hypersonic technology, applied in simulators, instruments, control/regulation systems, etc., can solve the problem of less research on real-time engine dynamic models, achieve good real-time performance, avoid iterative calculations, and simple calculations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

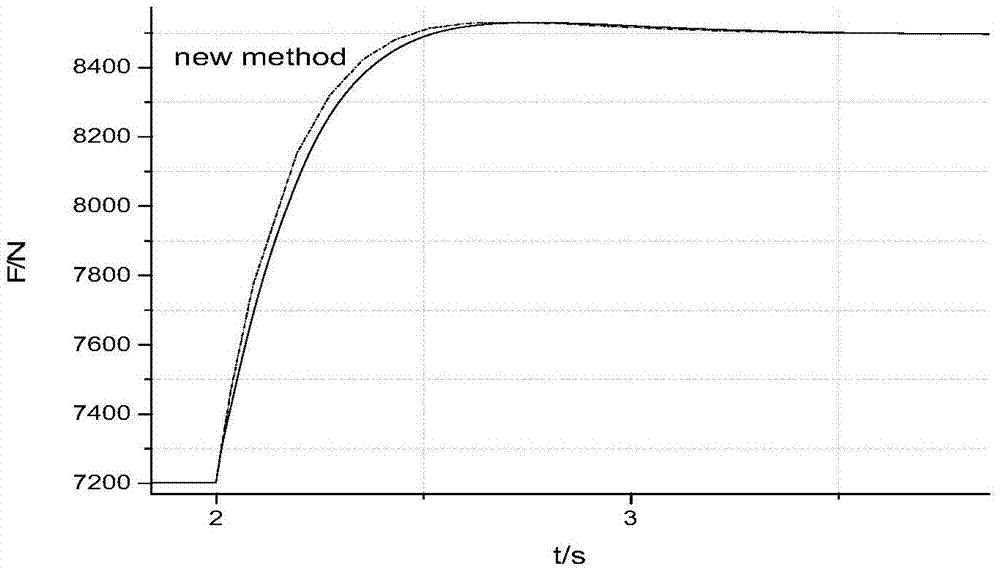

Examples

Embodiment Construction

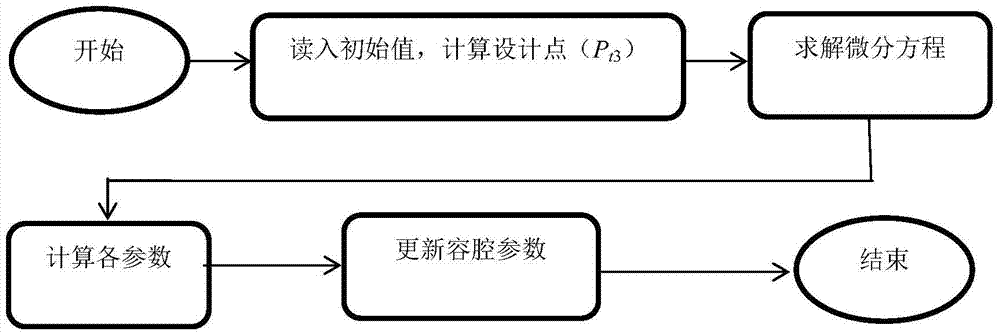

[0030] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

[0031] The object of the present invention is to propose a hypersonic scramjet real-time model that can accurately reflect the dynamic process of the hypersonic scramjet engine, is easy to solve, and has better real-time performance. A model suitable for real-time control should have the characteristics of extracting main features and reasonably simplifying them. The present invention makes the following simplifications in model construction:

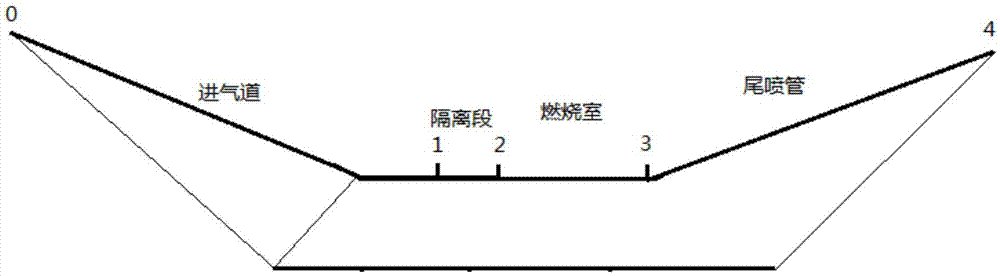

[0032] (1) The aircraft precursor and the scramjet inlet are coupled as one;

[0033] (2) The isolation section is regarded as a friction tube with equal cross-section;

[0034] (3) The combustion chamber only considers its volume effect;

[0035] (4) The tail nozzle of the scramjet is coupled with the rear body of the aircraft as a whole.

[0036] In this way, the complex three-dimensional flow problem of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com