Temperature rise prediction method for long downgrade driving brake for lorry

A prediction method and brake technology, applied in the direction of temperature control using electric methods, auxiliary controllers with auxiliary heating devices, etc., can solve problems such as brake failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

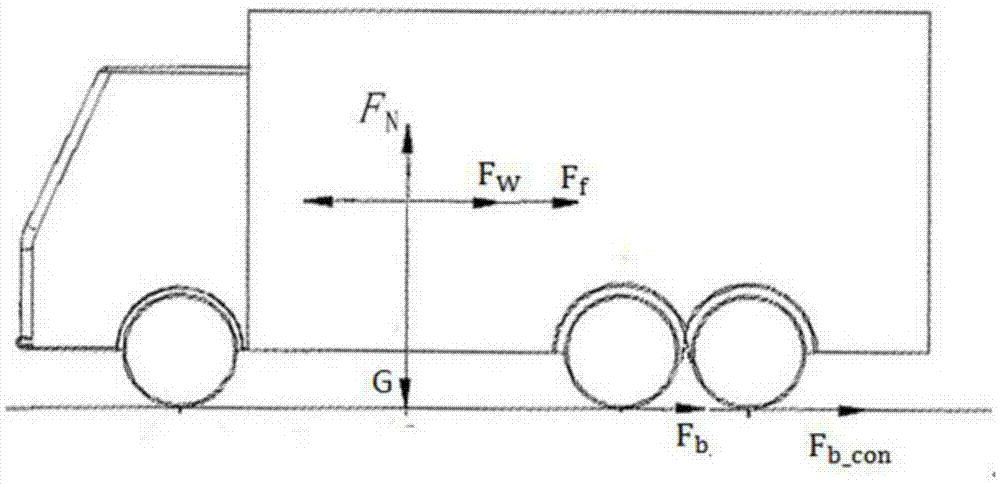

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0101] The object of this embodiment is Dongfeng Tianlong DFL4251A9 tractor, CSQ9401GYY tank type semi-trailer 3rd shaft brake. During the entire braking process, the transmission is placed in neutral and only the service brake is applied. Selected initial conditions: the ambient temperature of the brake drum is 23°C, and the steady vehicle speed is 44.23km / h. Record the brake drum temperature, and then compare the established brake heating model with the test results. The data of the brake heating test results and model simulation results are shown in Table 3.

[0102] Table 3 Comparison of the results of the third axis test and model simulation results of the first ramp test of the brake temperature rise

[0103]

[0104]

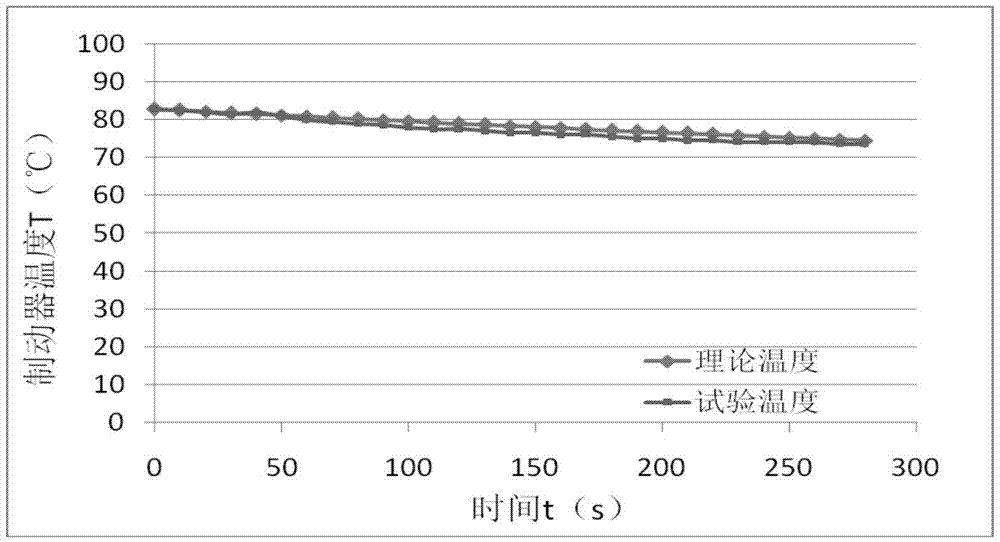

[0105] The whole test process lasted 311.13s. During the test, the brake temperature rose from 22.93°C to 44.07°C. The model simulation results showed that the brake temperature rose to 42.98°C, with a relative error of 2.48%. The test data is sa...

Embodiment 2

[0107] The objects of this embodiment are the same as those in Embodiment 1. Selected initial conditions: the ambient temperature of the brake drum is 55°C, and the steady vehicle speed is 44.39km / h. Record the brake drum temperature, and then compare the established brake heating model with the test results. The data of the brake heating test results and model simulation results are shown in Table 4.

[0108] Table 4 Comparison of the third axis test results and model simulation results of the second ramp test brake temperature

[0109]

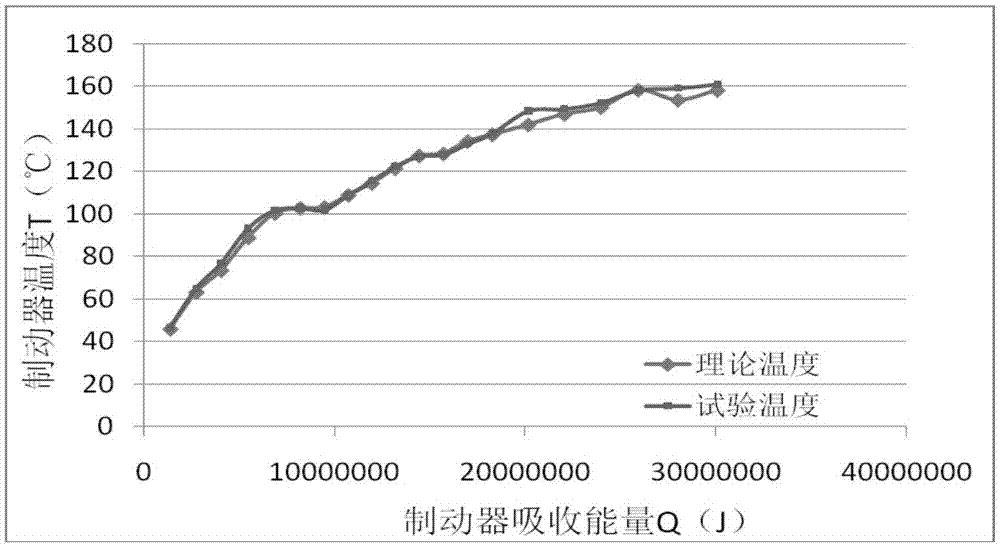

[0110] The whole test process lasted 340s. During the test, the brake temperature rose from 56.73°C to 83.20°C. The model simulation results showed that the brake temperature rose to 84.77°C, with a relative error of -1.89%. The test data is sampled every 10s, and the test results are compared with the model simulation results. The maximum relative error is 4.52%. The results are as follows Figure 5 shown.

Embodiment 3

[0112] The objects of this embodiment are the same as those in Embodiment 1. Selected initial conditions: Continuous ramp tests on five sections of road with different slopes, among which, the first section has a slope of 2.90%, a stable speed of 47.88km / h, and a driving distance of 307.90m; the second section has a slope of 4.50% , the stable vehicle speed is 47.76km / h, and the driving distance is 508.64m; the third section has a slope of 2.58%, the stable vehicle speed is 47.42km / h, and the driving distance is 505.68m; the fourth section has a slope of 2.72%, and the stable vehicle speed is 45.17km / h , the driving distance is 381.58m; the slope of the fifth section is 2.02%, the stable speed is 38.19km / h, and the driving distance is 574.00m. The data of the brake heating test results and model simulation results are shown in Table 5.

[0113] Table 5 The comparison between the test results of the third axis and the simulation results of the model for long downhill slopes wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com