Die bonding method for flip LED chips

An LED chip, flip-chip technology, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as unfavorable heat transfer of LED chips, affecting LED light output, and chips prone to skew, achieving small thickness and increasing LED light output. The effect of high efficiency and heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings of the specification.

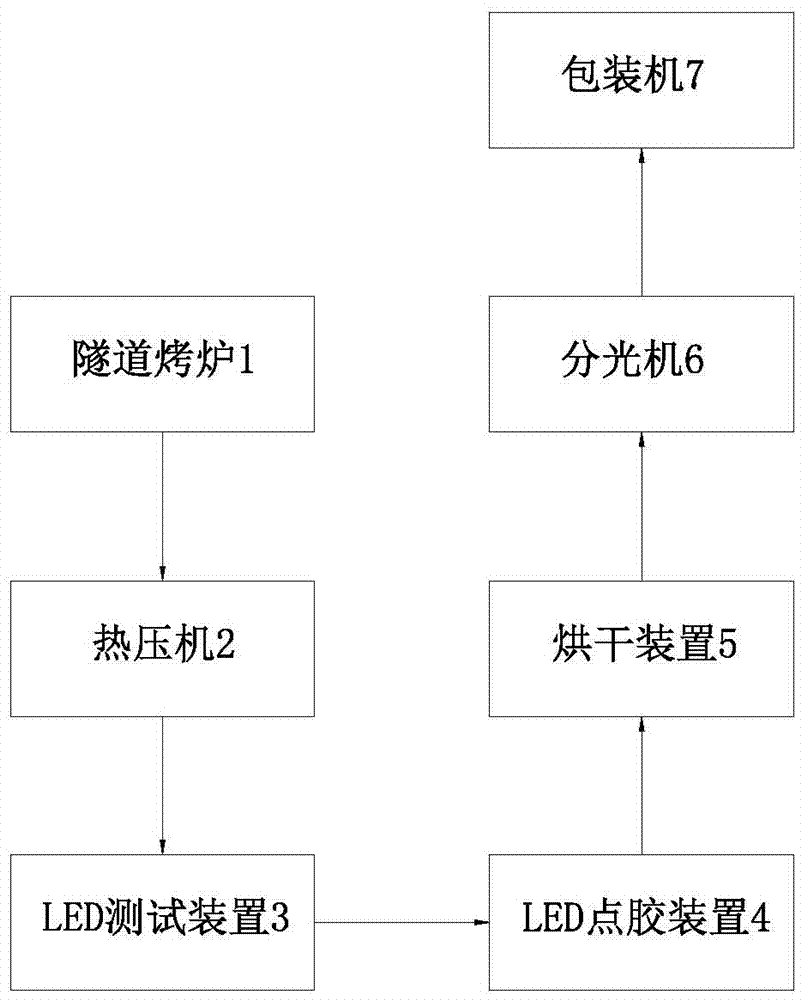

[0028] Such as figure 1 As shown, an LED crystal bonding equipment includes a tunnel oven 1, a hot press 2, an LED testing device 3, an LED dispensing device 4, a drying device 5, a spectroscope 6 and a packaging machine 7 in sequence according to the material conveying direction. Each equipment is docked through the conveyor track, which can realize automated production.

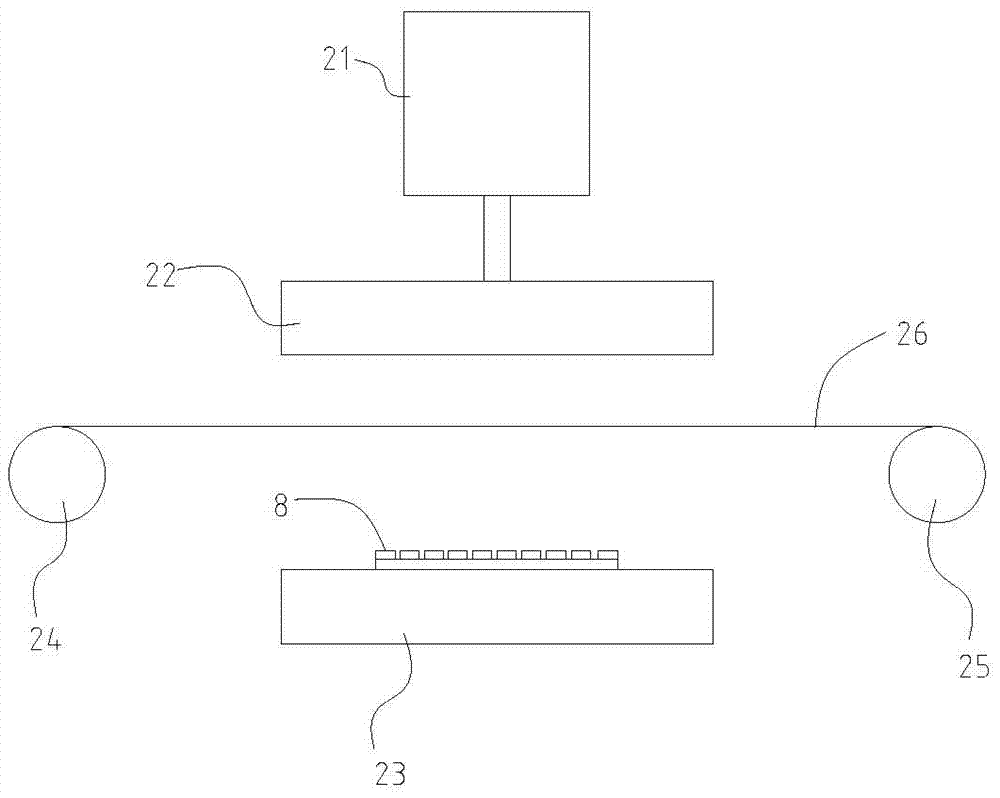

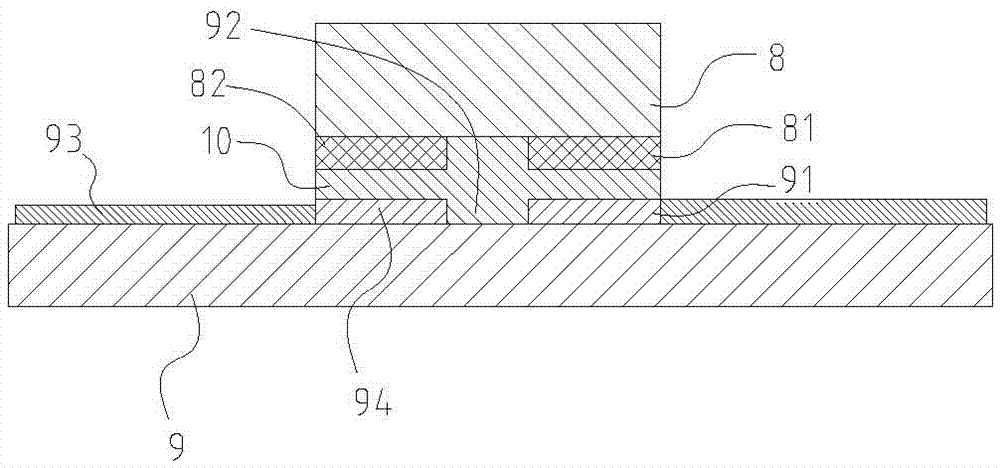

[0029] The principle of automated production: use conventional production equipment to realize glue dispensing and placement of flip-chip LED chips 8. After completing a unit of product, directly send it to tunnel oven 1, after 5 minutes of high temperature baking at 120 ℃, and then The product is sent to the hot press 2, the sensor detects the product and sends it to the hot pressing position of the hot press 2, and the hot press 2 heats the product; after completion, the product is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com