Modular H bridge cascade multi-level power electronic transformer control system

A cascading multi-level, power electronics technology, applied to electrical components, AC power input conversion to AC power output, AC power input conversion to DC power output, etc., can solve the problem of automatic mutual balance of three-phase power , can not meet the problems of fault ride-through control, unsatisfactory dynamic response performance, etc., and achieve the effect of good dynamic response performance, reduced adjustment time and overshoot, and reduced complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0032] The present invention is specifically introduced below in conjunction with accompanying drawing:

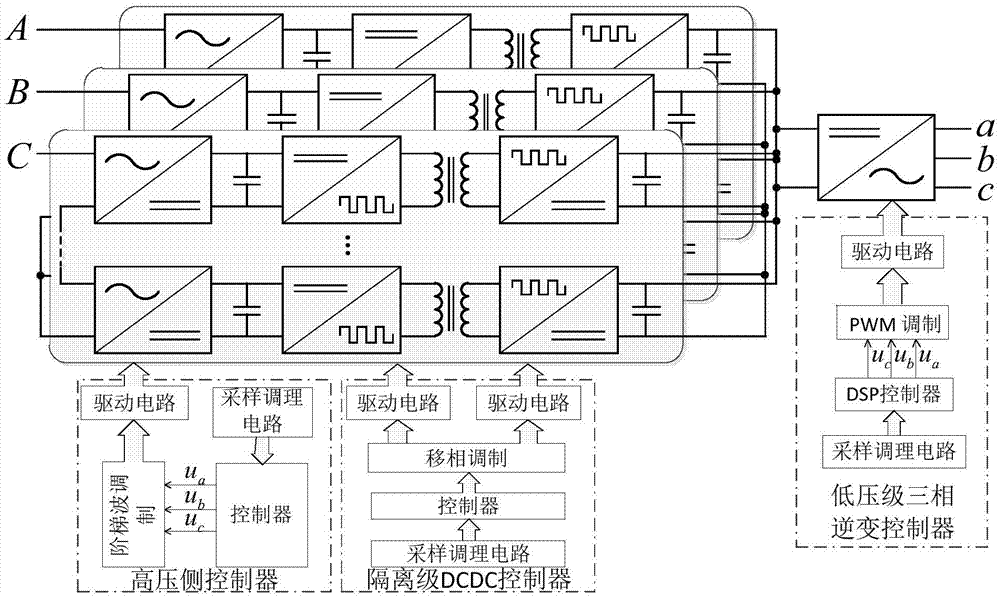

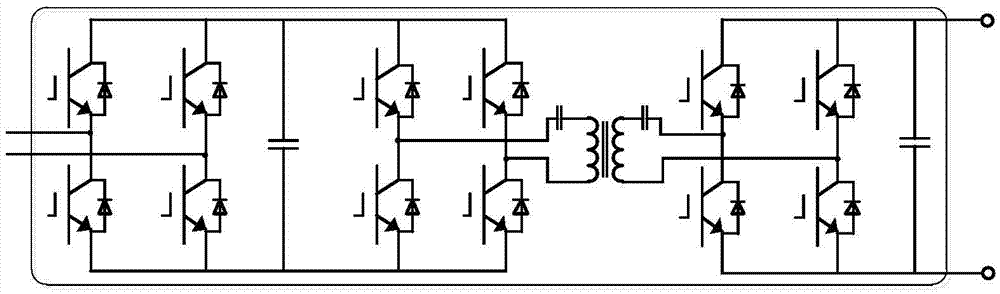

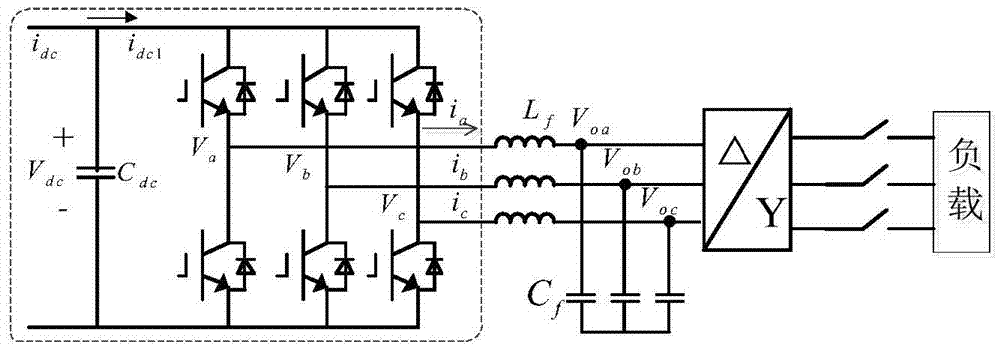

[0033] like figure 1 As shown, the modularized H-bridge cascaded multi-level power electronic transformer control system provided in this example, its system structure includes: a high-voltage stage rectifier circuit unit composed of multiple single-phase H-bridge rectifiers cascaded connected to the three-phase input grid 1. An isolation-level conversion circuit unit composed of multiple high-frequency DC / DC isolation converters connected in parallel to the number of single-phase H-bridge rectifiers. The hardware topology diagram of a single high-voltage rectifier circuit and isolation-level conversion circuit is as follows figure 2 As shown, the low-voltage inverter circuit unit connected to the output terminal of the isolation stage conversion circuit unit, its hardware topology diagram is as follows image 3 As shown, and the high-voltage side controller, the isolati...

example 2

[0058] In order to verify the performance of the high-voltage stage rectifier circuit unit in the control system provided by the present invention, in this example, the input of phase A voltage and phase B voltage is stable, and the voltage of phase C drops by 50% in 0.2s. The system is controlled, wherein, the A-phase reference voltage value waveform and the actual output capacitor voltage waveforms of each single-phase H-bridge rectifier in the A-phase are respectively as follows Figure 7 ~ Figure 8 Shown:

[0059] see Figure 7 , the reference voltage value of phase A is 10kV before 0.2s, and 12kV after 0.2s, it can be seen from the waveform that the DC voltage of each phase can track the reference value well;

[0060] see Figure 8 , the actual value of each single-phase H-bridge rectifier in phase A is about 630V before 0.2s, and about 800V after 0.2s. It can be seen that each single-phase H-bridge rectifier has better balance.

example 3

[0062] In order to verify the performance of the isolation level conversion circuit unit in the control system provided by the present invention, the system controls the system under the condition that the isolation level conversion output is set at 800V, and the bus voltage waveform at the output end of the high frequency DC / DC isolation converter like Figure 9 Shown: The bus voltage at the output end of the high-frequency DC / DC isolation converter stabilizes at 700V before 0.2s, and at 800V after 0.2s. It can be seen that the bus voltage at the output end can quickly track the reference value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com