Cu/ceramic material joint, method for manufacturing Cu/ceramic material joint, and substrate for power module

A manufacturing method and joint body technology, applied in the direction of ceramic layered products, chemical instruments and methods, applications, etc., can solve the problems of reduced joint rate, inability to provide reliable power module substrates, and degradation of ceramic substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

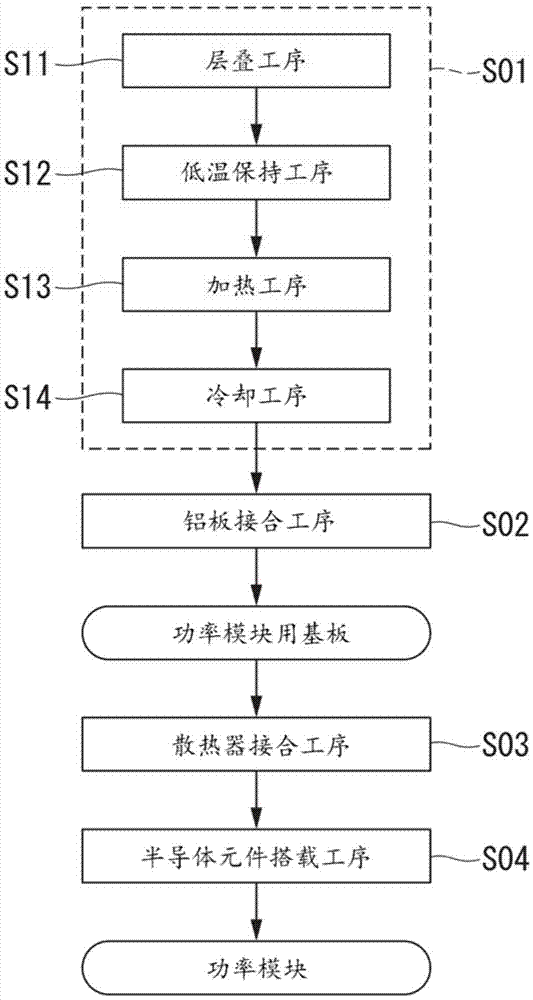

[0051] First, combine Figure 1 to Figure 5 A first embodiment of the present invention will be described.

[0052] The Cu-ceramic bonded body of the present embodiment includes a power module substrate 10 constituted by bonding a ceramic substrate 11 as a ceramic component and a copper plate 22 (circuit layer 12 ) as a copper component.

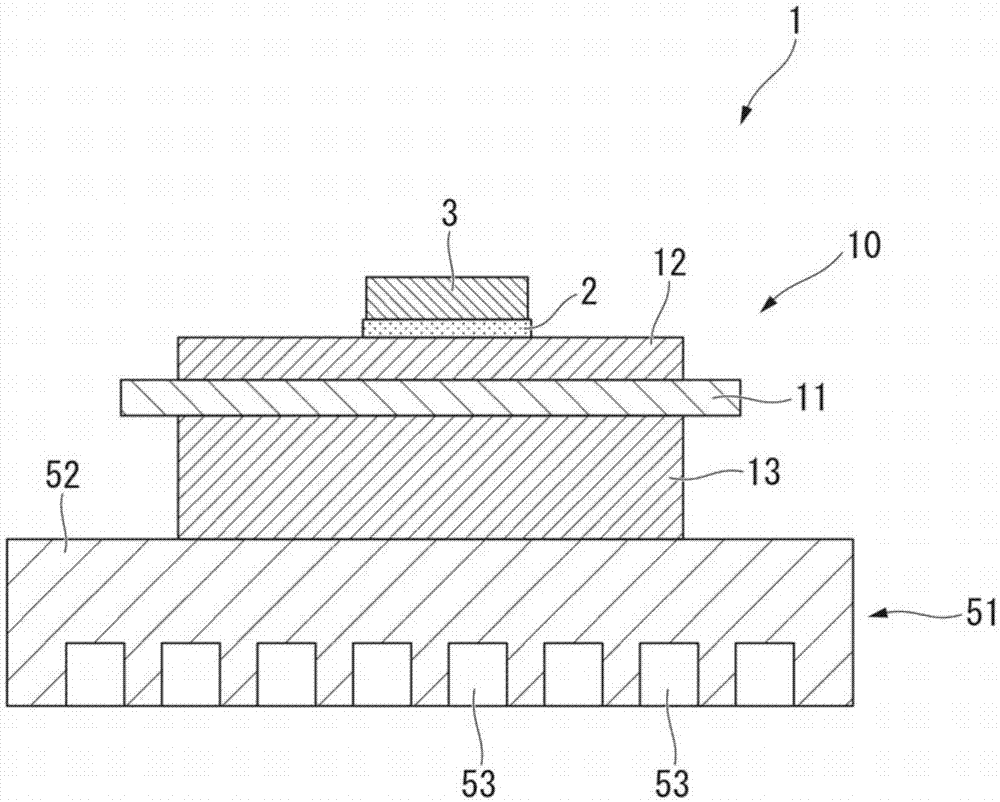

[0053] exist figure 1 The power module substrate 10 according to the first embodiment of the present invention and the power module 1 using the power module substrate 10 are shown in FIG.

[0054] The power module 1 includes: a power module substrate 10, on one side of the power module substrate 10 ( figure 1 The semiconductor element 3 bonded via the solder layer 2 is disposed on the other side of the power module substrate 10 ( figure 1 The lower side of the middle) radiator 51.

[0055] Among them, the solder layer 2 is, for example, a Sn-Ag-based, Sn-In-based, or Sn-Ag-Cu-based solder material.

[0056] The substrate 10 for a power ...

no. 2 approach

[0096] Second, combine Figure 6 to Figure 10 A second embodiment of the present invention will be described.

[0097] The Cu-ceramic bonded body of the present embodiment includes a power module substrate 110 constituted by joining a ceramic substrate 111 as a ceramic member and a copper plate 122 (circuit layer 112 ) and copper plate 123 (metal layer 113 ) as copper members.

[0098] Figure 6 2 shows a power module substrate 110 according to a second embodiment of the present invention and a power module 101 using the power module substrate 110 .

[0099] The power module 101 includes a power module substrate 110, and on one side of the power module substrate 110 ( Figure 6 The semiconductor element 103 bonded via the first solder layer 102 is disposed on the other side of the power module substrate 110 ( Figure 6 The lower side of the middle) radiator 151.

[0100] The power module substrate 110 includes a ceramic substrate 111, and is disposed on one surface of the ...

no. 3 approach

[0135] Second, combine Figure 11 to Figure 15 A third embodiment of the present invention will be described.

[0136] In the Cu-ceramic bonded body of the present embodiment, if Figure 11 As shown, a power module substrate 210 is provided, and the power module substrate 210 is constituted by bonding a ceramic substrate 211 as a ceramic component and a copper plate 222 (circuit layer 212 ) as a copper component.

[0137] The ceramic substrate 211 is made of high insulating Al 2 o 3 (alumina) configuration, and its structure is the same as that of the second embodiment.

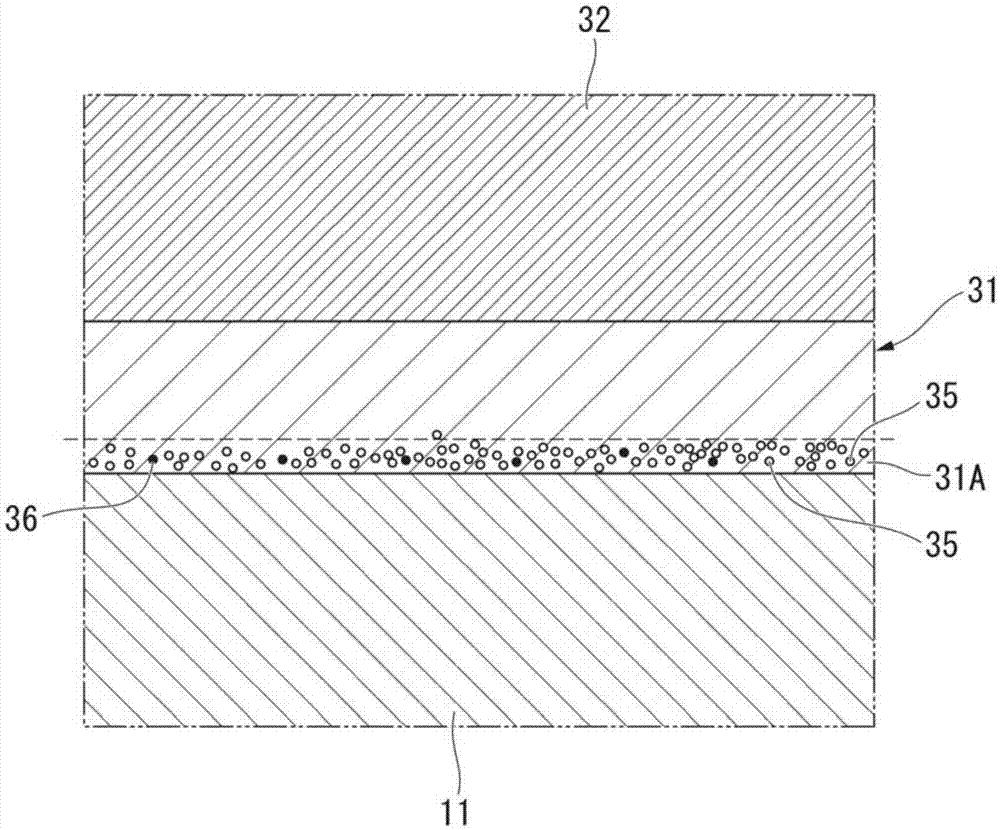

[0138] Such as Figure 14 As shown, the circuit layer 212 is formed by bonding a copper plate 222 made of copper or a copper alloy to one surface of the ceramic substrate 211, and its structure is the same as that of the second embodiment.

[0139] Among them, such as Figure 14 As shown, the ceramic substrate 211 and the circuit layer 212 (copper plate 222 ) are bonded using Ag—Ti based solder paste 224 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com