Extractive distillation process

A technology of extraction and liquid extractant, applied in the field of extractive distillation, can solve problems such as ineffectiveness and difficulty in separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

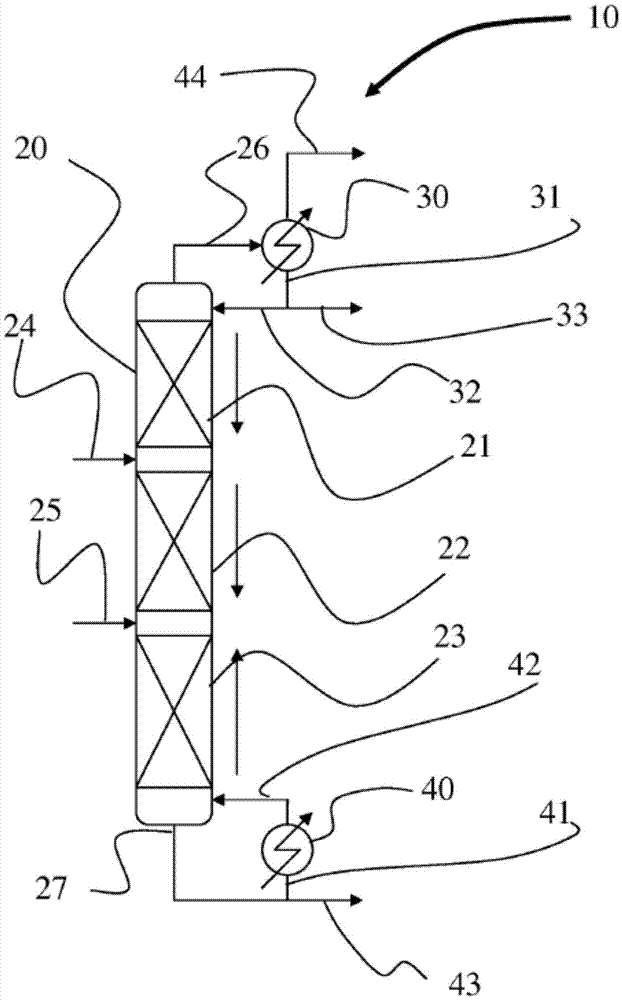

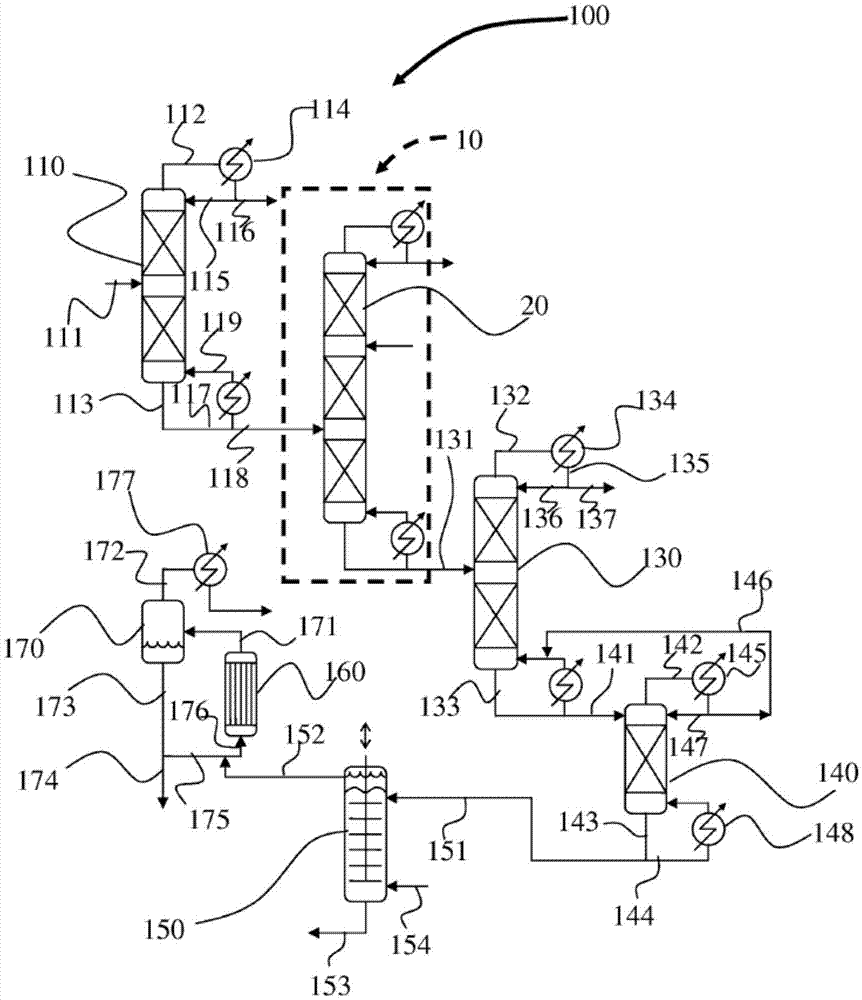

Method used

Image

Examples

Embodiment 1

[0074] In this example 1, several laboratory experiments were performed, including providing a mixture of extractant, DEB, EVB, and DVB; and boiling the mixture in a single-stage vapor-liquid equilibrium (VLE) under vacuum while still measuring at equilibrium The vapor and liquid composition in the state and determine the resulting relative volatility of the components in the mixture. These relative volatility were compared with the relative volatility obtained from similar experiments using a mixture of DEB, EVB, and DVB in the absence of the extractant to determine the degree of enhancement caused by the use of the extractant. The results of these experiments are described in Table I-VI below:

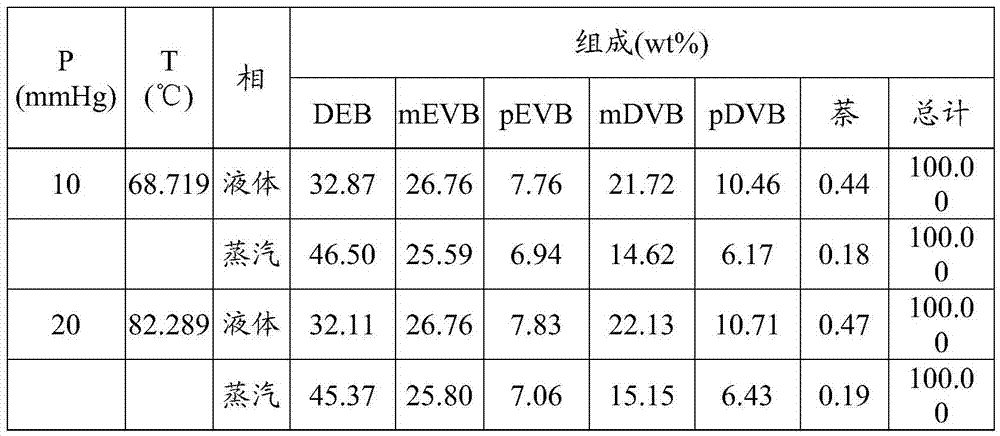

[0075] Table I-DEB / EVB / DVBVLE results-no extractant

[0076]

[0077] Table II-DEB / EVB / DVB relative volatility calculation results-no extractant

[0078]

[0079] Table III-Sulfolane 1.5 for 1DEB / EVB / DVBVLE results

[0080]

[0081]

[0082] Table IV-Calculation results of relative vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com