On-line blockage cleaning method for SCR (selective catalytic reduction) denitration catalyst

A denitrification catalyst and denitrification technology, applied in chemical instruments and methods, catalyst regeneration/reactivation, physical/chemical process catalysts, etc., can solve problems such as increasing the burden on enterprises and cumbersome operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1 An SCR denitrification catalyst online plugging removal equipment

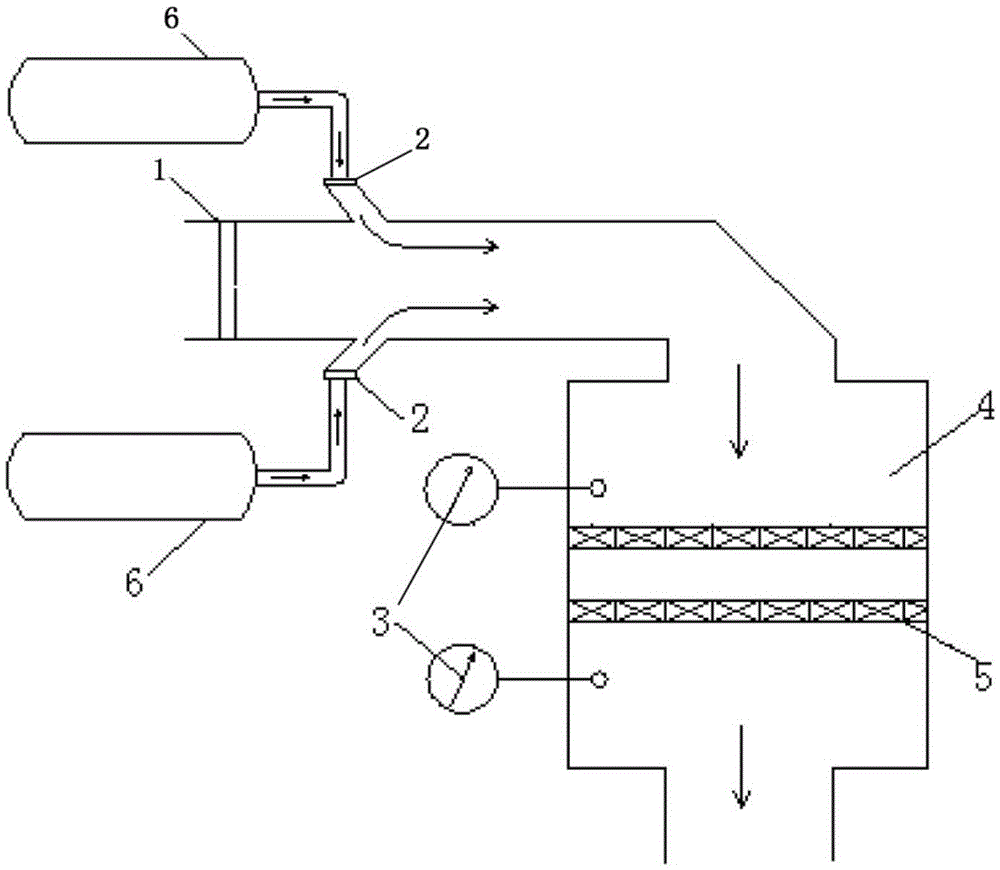

[0033] For the on-line declogging equipment with SCR denitration catalyst described in this embodiment, the structural diagram (longitudinal section) is shown in figure 1 , including a main valve 1, 3 vents 2 with valves (in figure 1 Only two vents are shown in the middle, and the third one is not shown), three compressed air tanks 6 , an SCR denitration reactor 4 with a built-in SCR denitration catalyst 5 , and two pressure detectors 3 . The main valve 1 is arranged at the entrance of the SCR denitrification reactor 4, and is connected with the SCR denitrification reactor 4 through a pipeline; the vent 2 with a valve is arranged between the main valve 1 and the SCR denitration reactor Between the catalysts 5; the vents 2 with valves are each independently configured with a compressed air tank 6, and the compressed air tanks 6 pass through the vents 2 with valves and the SCR denitrification...

Embodiment 2

[0034] Example 2 A method for online declogging of SCR denitrification catalyst

[0035]The SCR denitrification reactor of this embodiment is an out-of-stock reactor of a flue gas purification system in a thermal power plant, and the service life of the catalyst is 3 years. Utilize the equipment described in embodiment 1, carry out SCR denitrification catalyst on-line declogging, for convenience of description, described vent 3 with valve is called No. 1 vent respectively, No. 2 vent (not shown) from bottom to top ) and vent number 3. Including the following operations:

[0036] Close the main valve 1 at the entrance of the SCR reactor 4, open the compressed air tank connected to the No. 1 vent 2 and the valve of the No. 1 vent 2, close the valves of the No. 2 and No. 3 vents, and the compressed air is ventilated through No. 1 Port 2 enters SCR denitration reactor 4. Observe and record the pressure detector 3 reading every 2 minutes. In the process of unclogging, the inl...

Embodiment 3

[0041] Example 3 A method for online declogging of SCR denitrification catalyst

[0042] The SCR denitrification reactor of this embodiment is an out-of-stock reactor of a flue gas purification system in a thermal power plant, and the service life of the catalyst is 4.5 years. The structure of the SCR denitrification catalyst online declogging equipment utilized is the same as that of Embodiment 1. For ease of description, the vents 3 with valves are respectively called No. 1 vents and No. 2 vents (not shown) from bottom to top. ) and vent number 3. Including the following operations:

[0043] Close the main valve 1 at the entrance of the SCR reactor 4, open the compressed air tank 6 connected to the No. 1 vent 2 and the valve of No. 1 vent 2, close the valves of No. 2 and No. 3 vents, and the compressed air passes through No. The vent 2 enters the SCR denitration reactor 4 . Observe and record the pressure detector 3 reading every 2 minutes. In the process of unclogging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com