Printing device for printing label on surface of industrial product

A technology for printing equipment and industrial products, applied in printing, typewriters, transfer materials, etc., can solve problems such as operation errors, time-consuming and laborious, space limitations, etc., and achieve the effect of simple structure, convenient use, and reduced space height.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

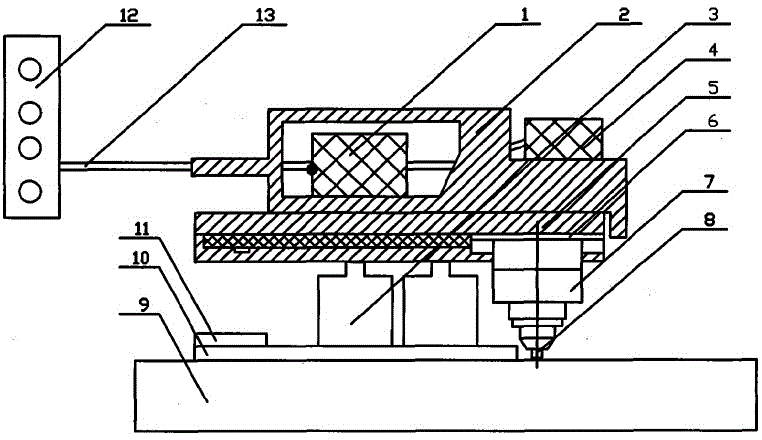

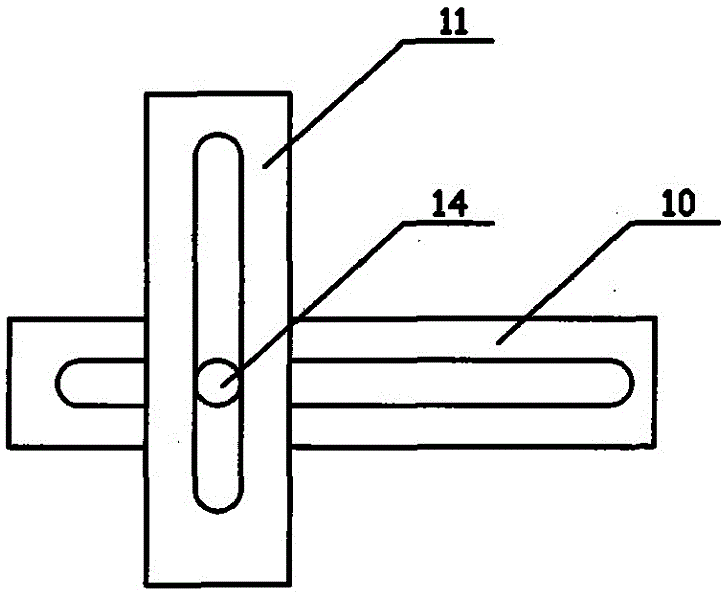

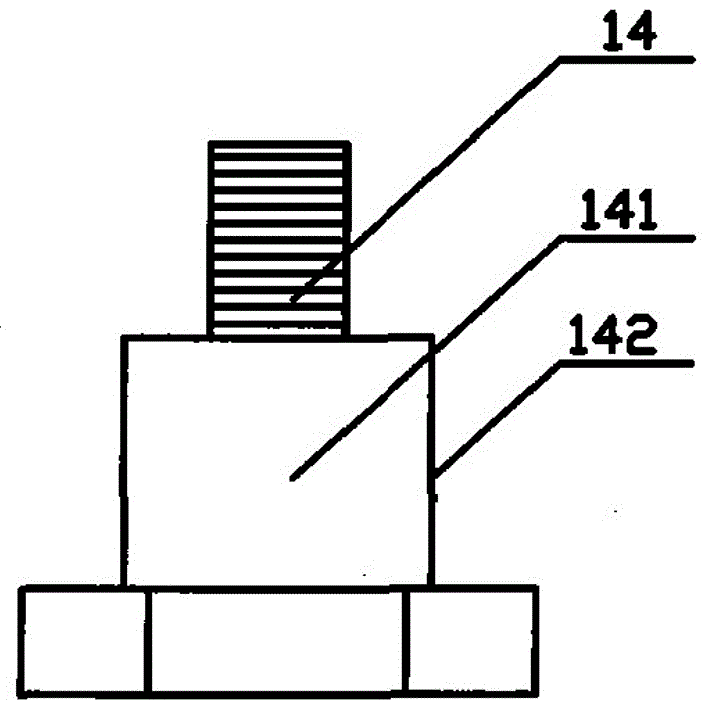

[0018] In order to further illustrate the present invention, further describe below in conjunction with accompanying drawing:

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, a printing device of the present invention that prints marks on the surface of industrial products includes a control system 12 and an execution system. The control system 12 includes a controller. The control system 12 is connected to the controller separately through a cable 13. The execution system includes Frame 2, set the workbench 5 that controls the movement of the needle base 1 according to the design trajectory of the plane X direction, the workbench 5 is slidably connected to the plane Y direction relative to the frame 2, and the marking printer also includes a fixed tooling, which is formed along the plane X The positioning strip-shaped orifice plate 10 moving in the Y direction, the positioning strip-shaped orifice plate 11 moving along the plane Y dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com