Macroporous cement concrete capable of adsorbing carbon oxide and preparation method of macroporous cement concrete

A technology for absorbing carbon dioxide and cement concrete, applied in cement production, etc., to reduce noise, improve road performance, and accelerate curing and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment provides a kind of macroporous cement concrete capable of absorbing carbon dioxide, which is made of the following raw materials in parts by weight: cement: 100 parts, coarse aggregate: 385 parts, stone powder or gravel: 15.5 parts, geopolymerization Material binder: 5 parts, water reducing agent: 4.6 parts, water: 29.5 parts;

[0030] The cement is ordinary Portland cement with 42.5MPa;

[0031] Coarse aggregate is 6-22mm single-grain gradation.

[0032] Stone powder or gravel is a mixture of Fushan stone, pyroxene and Qinghe stone in a mass ratio of 2:2:1

[0033] Preparation:

[0034] Mix the stone powder or gravel, 10% formula design weight of water and sodium bicarbonate for 30s according to the proportion, so that the sodium bicarbonate can fully reflect the silica on the surface of fushan stone and / or pyroxene, and reduce the effect of silica on adsorption and solidification the effect of carbon dioxide;

[0035] Then add coarse aggregate, Qin...

Embodiment 2

[0041] This embodiment provides a kind of macroporous cement concrete capable of absorbing carbon dioxide, which is made of the following raw materials in parts by weight: cement: 100 parts, coarse aggregate: 314 parts, stone powder or gravel: 5 parts, geopolymerization Material binder: 4.6 parts, water reducer: 4.6 parts, water: 29.5 parts;

[0042] The cement is ordinary Portland cement with 42.5MPa;

[0043] Coarse aggregate is 6-22mm single-grain gradation.

[0044] Stone powder or gravel is a mixture of Fushan stone and Qinghe stone in a mass ratio of 2:1.

[0045] The preparation method of this embodiment is basically the same as that of Example 1.

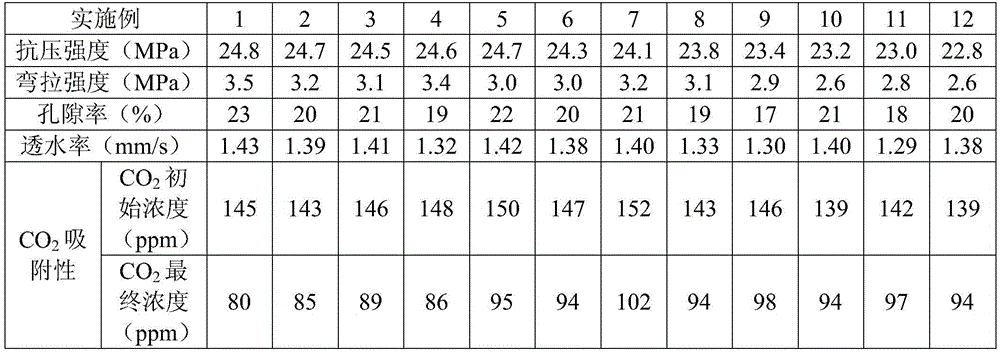

[0046] The performance test method of this embodiment is the same as that of Example 1, and the performance test results are shown in Table 1.

Embodiment 3

[0048] This embodiment provides a kind of macroporous cement concrete capable of absorbing carbon dioxide, which is made of the following raw materials in parts by weight: cement: 100 parts, coarse aggregate: 368 parts, stone powder or gravel: 5 parts, geopolymerization Material binder: 4.6 parts, water reducer: 4.6 parts, water: 29.5 parts;

[0049] The cement is ordinary Portland cement with 42.5MPa;

[0050] Coarse aggregate is 6-22mm single-grain gradation.

[0051]Stone powder or gravel is a mixture of pyroxene and Qinghe stone in a mass ratio of 2:1.

[0052] The preparation method of this embodiment is basically the same as that of Example 1.

[0053] The performance test method of this embodiment is the same as that of Example 1, and the performance test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com