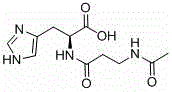

Preparing method for N-acetyl-L-carnosine

A technology of acetyl and carnosine, applied in the field of preparation of N-acetyl-L-carnosine, can solve the problems of complex process, troublesome processing, low yield and the like, and achieve the effects of high HPLC purity, short synthesis route and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Preparation of N-acetyl-β-alanine (I)

[0037] In a 250mL reaction flask, add 180mL of chloroform, 30g of β-alanine (0.337mol), 37.8g of acetic anhydride (0.371mol), raise the temperature to 60°C, and react for 5 hours. The sampled ninhydrin does not develop color, and the temperature is lowered to 4°C , stirred for 1 hour, suction filtered to obtain a solid, and dried to obtain 42 g of product (I), the yield was 95.4%, and the HPLC purity was ≥99.3%.

Embodiment 2

[0039] Preparation of N-acetyl-β-alanine (I)

[0040] In a 500mL reaction flask, add 360mL of dichloromethane, 60g of β-alanine (0.674mol), 48.5g of acetic acid (0.808mol), raise the temperature to 45°C, and react for 3 hours. The sampled ninhydrin does not develop color, and the temperature is lowered to 4 ℃, stirred for 1 hour, filtered to obtain a solid, and dried to obtain 82.5 g of product (I), with a yield of 93.4% and an HPLC purity of ≥99.3%.

Embodiment 3

[0042] Preparation of N-acetyl-β-alanine (I)

[0043] In a 1000mL reaction flask, add 360mL toluene, 120g β-alanine (1.348mol), 111.2g acetyl chloride (1.417mol), heat up to 50°C, react for 5 hours, sample ninhydrin does not develop color, cool down to -3 °C, stirred for 1 hour, filtered with suction to obtain a solid, and dried to obtain 169.0 g of product (I), with a yield of 95.7% and an HPLC purity of ≥99.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com