High-glossiness anti-scraping rapidly-formed polyolefin material

A polyolefin and scratch-resistant technology, applied in the polymer field, can solve the problems of increased cost and long molding cycle, and achieve the effect of improving scratch resistance, improving surface hardness and shortening molding cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0047] After the above components are fully mixed in a high-speed mixer, they are extruded and granulated by a twin-screw extruder to obtain the product. The obtained products are subjected to relevant experimental tests, the tensile test is tested according to GB / T1040, the notched impact is tested according to GB / T1843, and the ball pressure temperature is tested according to GB / T5169.21. The test results are shown in the table below:

[0048]

[0049]

Embodiment 5-8

[0052] After the above components are fully mixed in a high-speed mixer, they are extruded and granulated by a twin-screw extruder to obtain the product. The obtained products are subjected to relevant experimental tests, the tensile test is tested according to GB / T1040, the notched impact is tested according to GB / T1843, and the ball pressure temperature is tested according to GB / T5169.21. The test results are shown in the table below:

[0053]

Embodiment 9-12

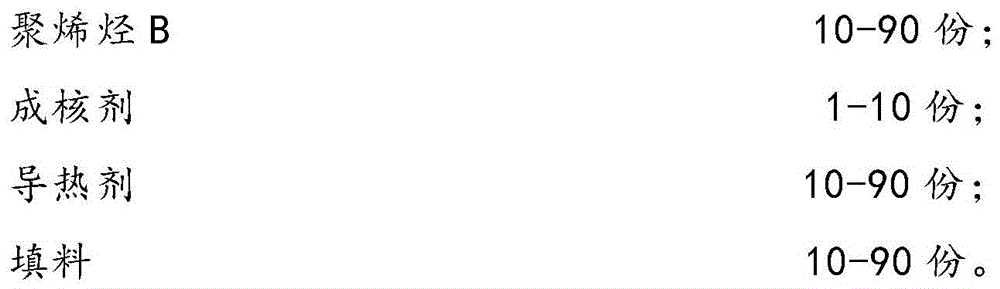

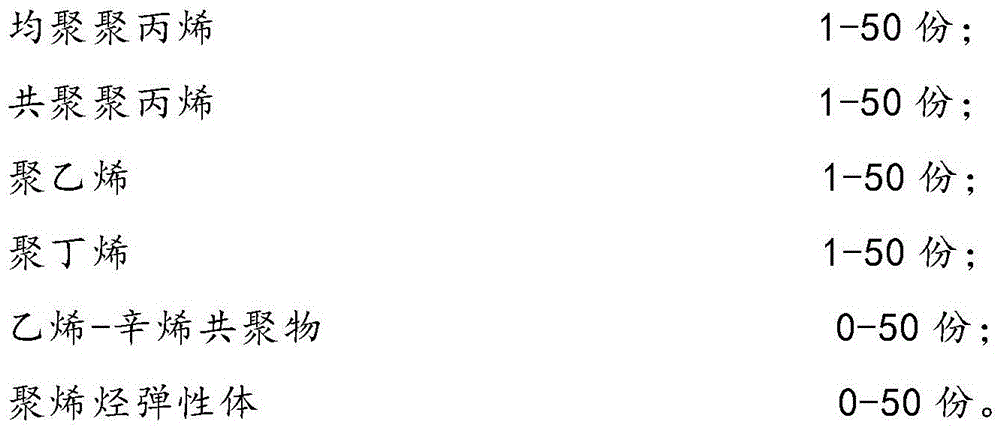

[0055]

[0056]

[0057] After the above components are fully mixed in a high-speed mixer, they are extruded and granulated by a twin-screw extruder to obtain the product. The obtained products are subjected to relevant experimental tests, the tensile test is tested according to GB / T1040, the notched impact is tested according to GB / T1843, and the ball pressure temperature is tested according to GB / T5169.21. The test results are shown in the table below:

[0058] project

[0059] It can be seen from the above examples that when the amount of masterbatch is greater than or equal to 50%, the molding cycle can be shortened by more than 20%. It also contains a heat conducting agent, which can accelerate heat loss and shorten cooling time. Due to the synergistic effect of the two, the molding cycle is shortened. Since the material itself does not require high thermal conductivity, the amount of thermally conductive filler does not need to be added. The Rockwell h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com