Ground Control Test Safety Valve

A ground control and safety valve technology, which is used in wellbore/well valve devices, wellbore/well components, earth-moving drilling, etc., can solve the problem of high labor intensity, large data deviation, and abnormal situations that cannot be dealt with in time and other problems, to achieve the effect of low labor intensity and small data deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

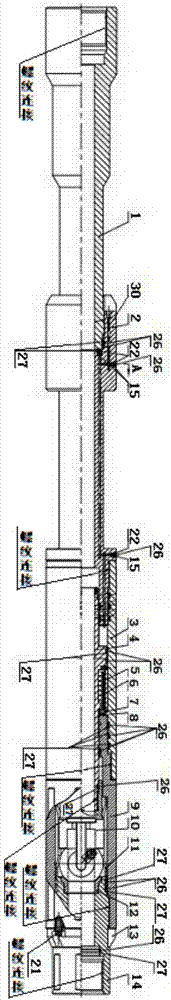

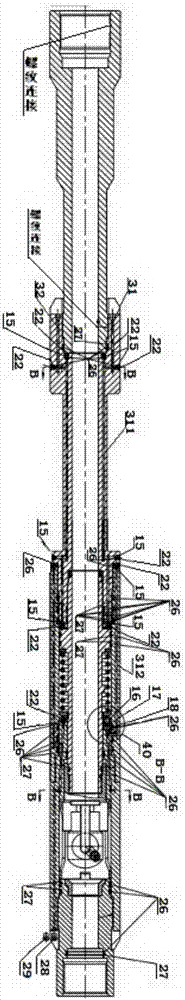

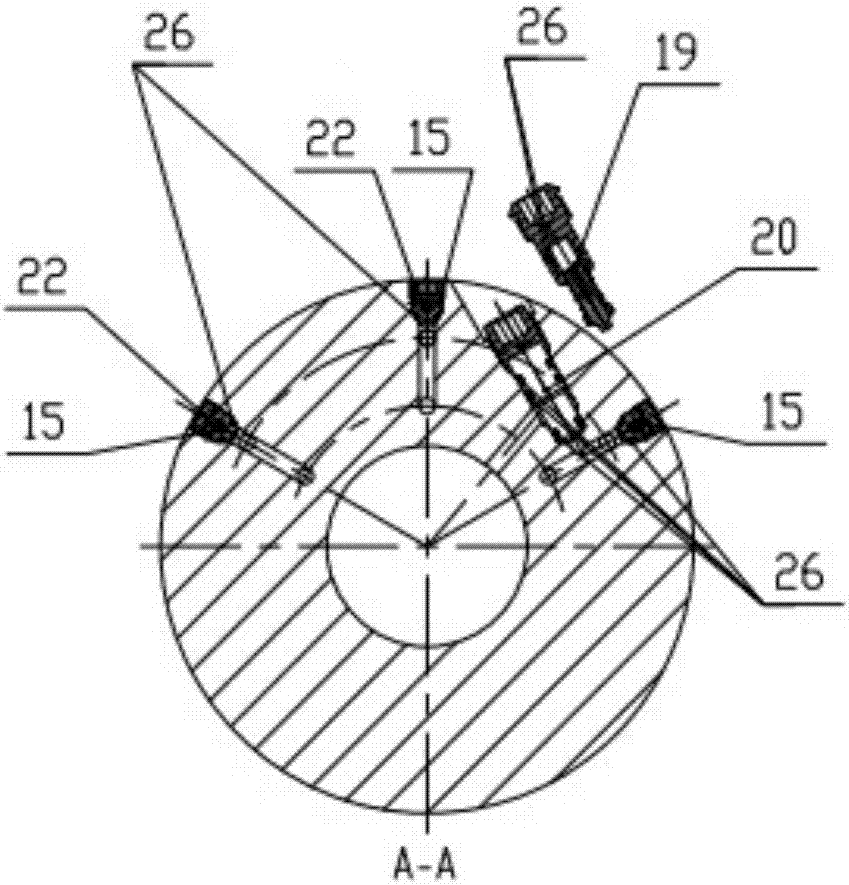

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0020] A ground control test safety valve with a structure such as figure 1 , figure 2 As shown, a cylindrical annular structure is adopted, including upper joint 1, duck neck outer cylinder 2, spring outer cylinder 3, piston mandrel 4, spring 6, check valve 40, ball valve outer cylinder 9, ball valve assembly 10, lower limit The ball seat 12 and the lower joint 14, the upper joint 1, the duck neck outer cylinder 2, the spring outer cylinder 3, the ball valve outer cylinder 9 and the lower joint 14 are sequentially fixedly connected to form a hollow shell, and the piston mandrel 4, The spring 6, the one-way valve 40, the ball valve assembly 10 and the lower limit ball seat 12 are sequentially arranged on the shell formed by the upper joint 1, the duck neck outer cylinder 2, the spring outer cylinder 3, the ball valve outer cylinder 9 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com