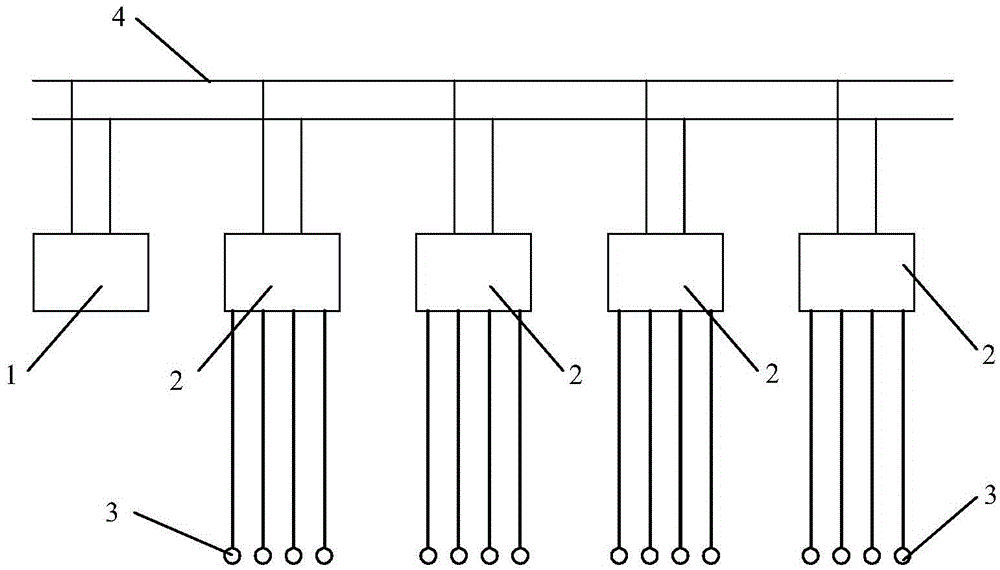

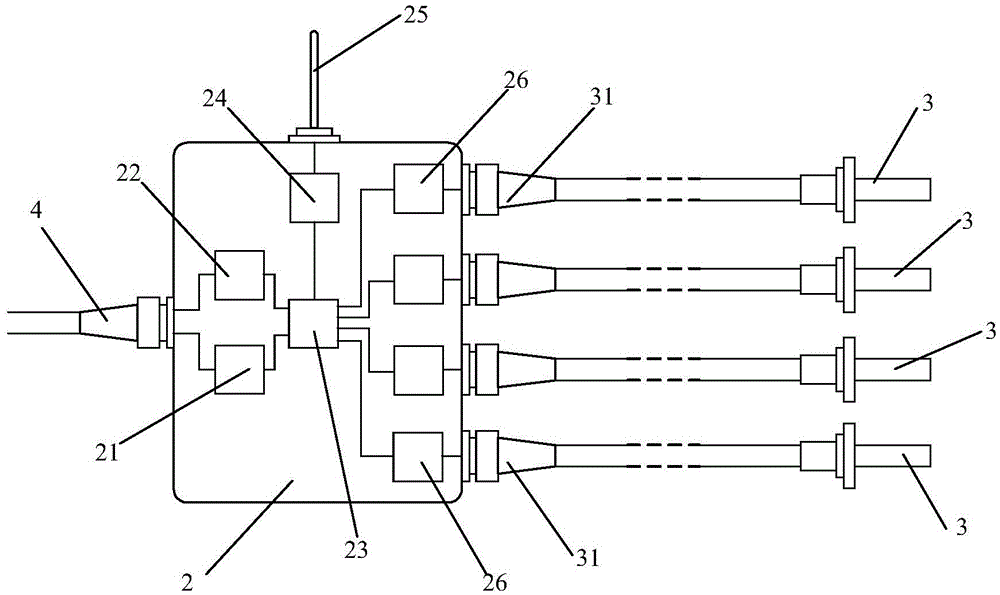

Train axle temperature monitoring system based on fluorescence fiber temperature measurement

A fluorescent optical fiber and monitoring system technology, applied in the field of temperature detection system of train axles, can solve the problems of poor anti-electromagnetic interference, cracking, false alarms, etc., and achieve good anti-electromagnetic interference performance, reliable connection and communication, and accurate temperature measurement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0016] Nowadays, fiber optic temperature sensors with many principles have been developed, but due to reasons such as cost, accuracy, and reliability, fiber grating type, fluorescent type, and Raman type are currently widely used. Among them, the fiber grating sensor embeds the fiber grating in the measured part. When the temperature changes, the period and refractive index of the grating change, resulting in a change in the peak reflection wavelength; the advantages of the fiber grating sensor are high temperature measurement accuracy and simple wiring. All sensors can be connected in series, and only 1 or 2 connectors are connected, which greatly reduces the wiring cost. The disadvantage is that the demodulator is very expensive, but the overall cost of the system can be reduced by connecting a large number of sensors in series and parallel. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com