Cooling device for travelling-wave tube amplifier

A traveling wave tube amplifier and cooling device technology, applied in the cooling method of transit time type electron tubes, discharge tubes, transit time type electron tubes, etc., can solve problems such as drop, difficult internal temperature, influence on operation stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing.

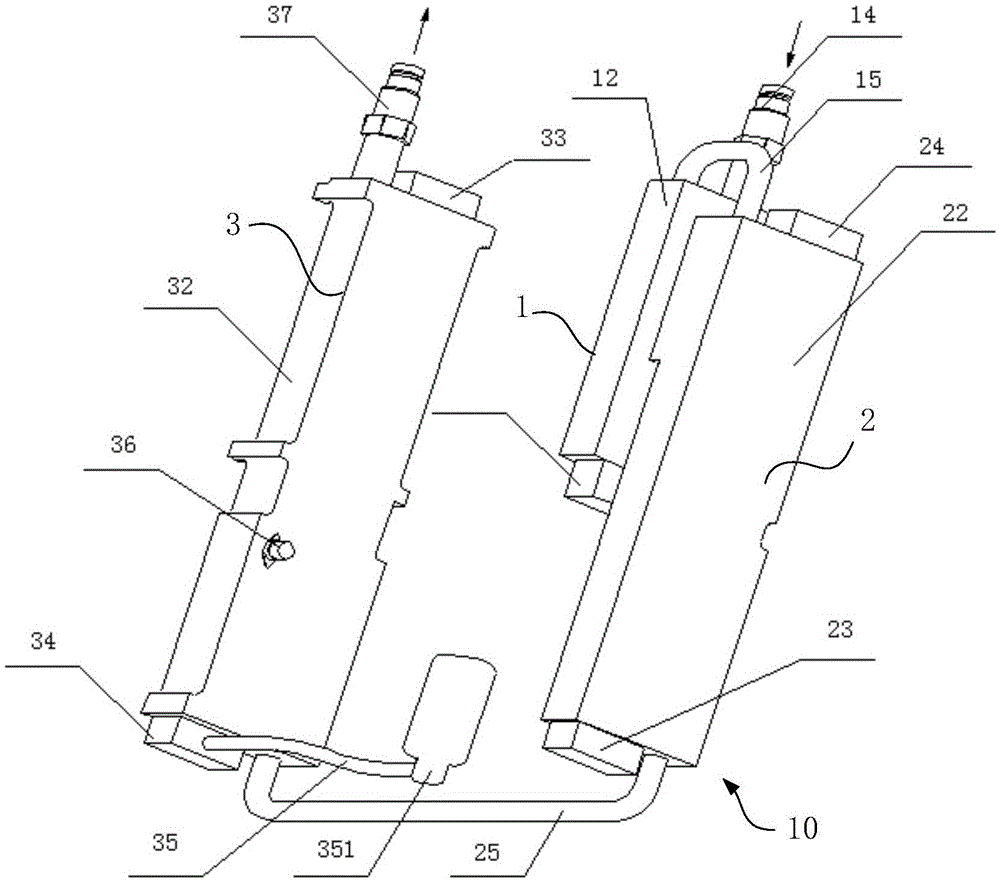

[0029] Such as figure 1 As shown, a cooling device 10 for a traveling wave tube amplifier includes a first cooling plate 1 , a second cooling plate 2 and a third cooling plate 3 . The first cooling plate 1, the second cooling plate 2, and the third cooling plate 3 are provided with flow channels, and the flow channels in the first cooling plate 1, the second cooling plate 2, and the third cooling plate 3 pass through external pipelines in sequence connected.

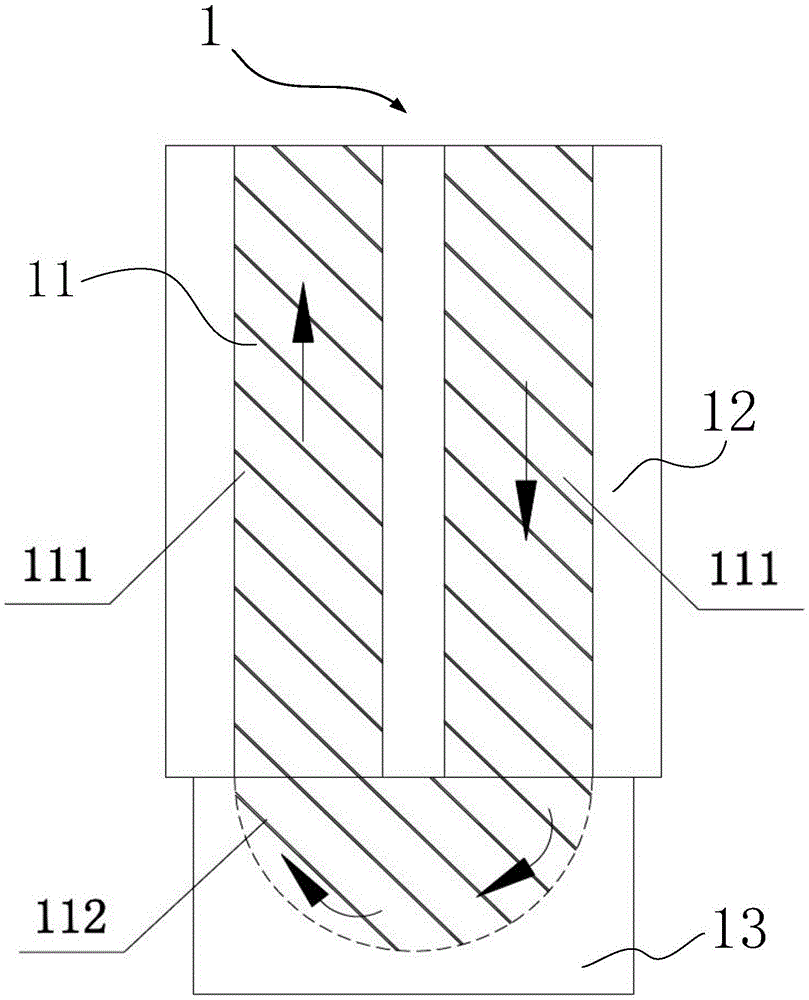

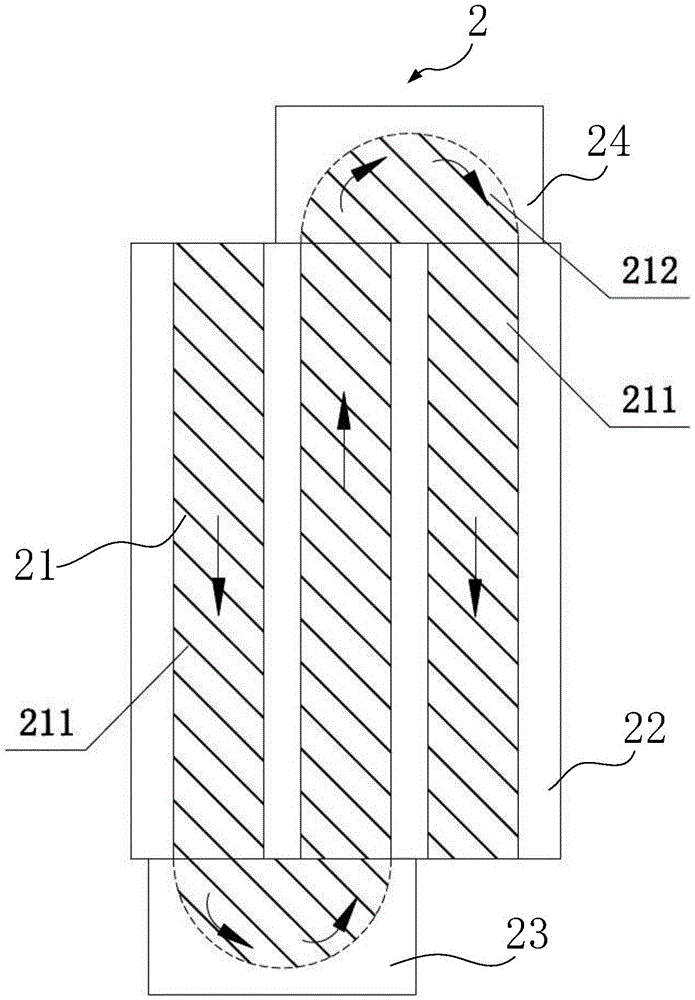

[0030] Such as figure 2 As shown, the first cooling plate 1 includes a first body 12 and a first deflector block 13 . The first body 12 is a roughly plate-shaped structure. The first deflector block 13 has a substantially straight hexahedron structure. The outer contour of the first deflector block is a roughly cubic structure. The first guide block 13 is disposed at one end of the first body 12 . The first co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com