A ceramic razor blade

A technology for razors and knives, applied in the field of ceramic razor knives, can solve the problems of reducing production costs, fragile ceramic knives, etc., and achieves the effects of high density, easy industrial production, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

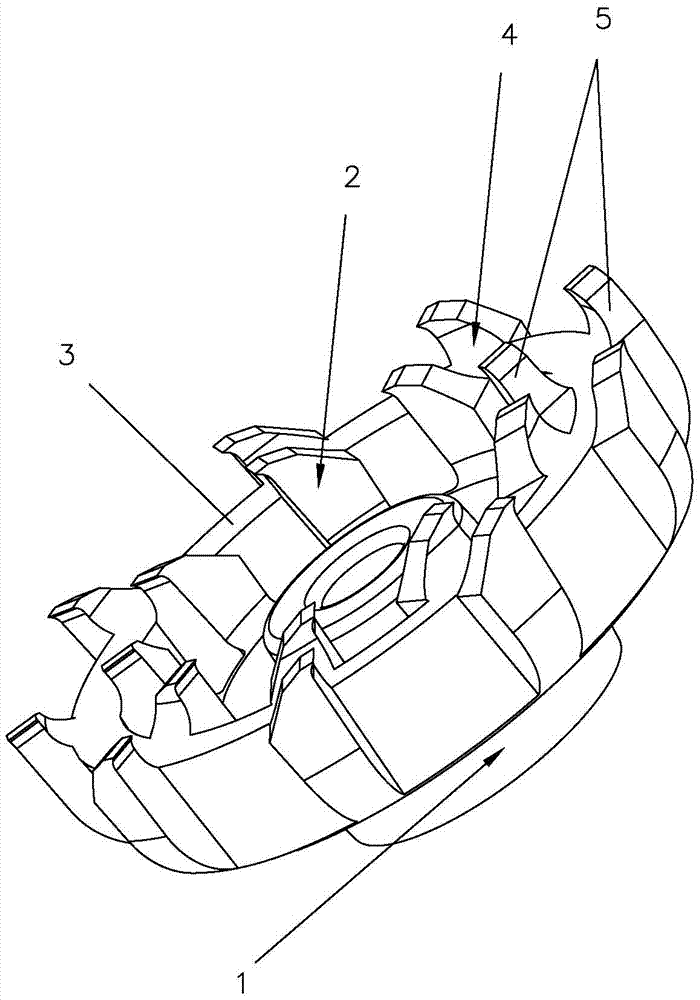

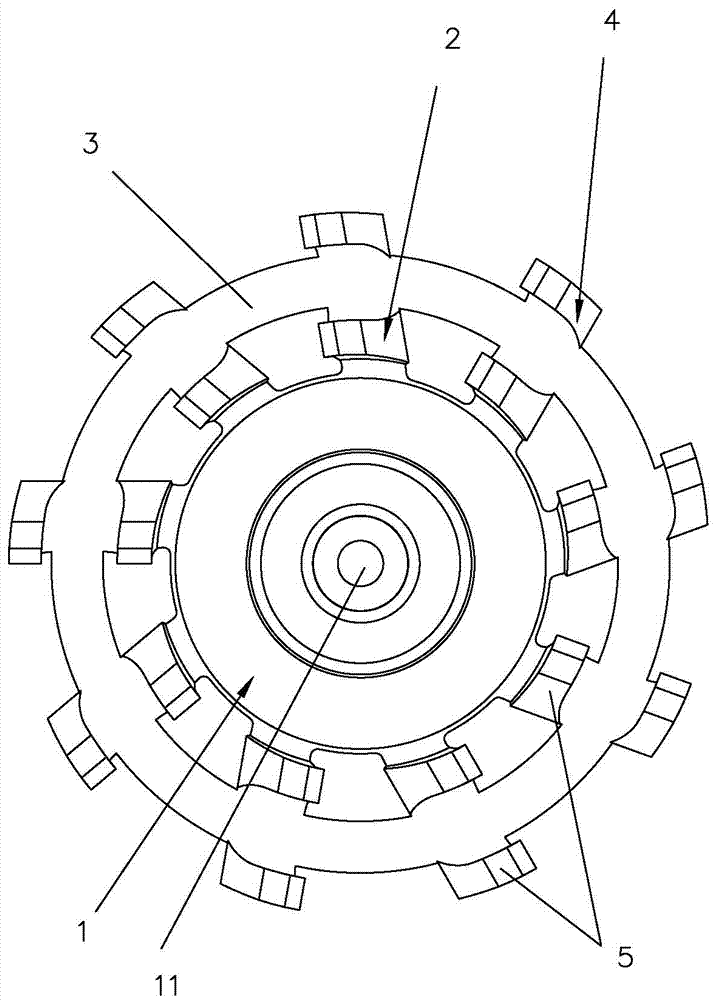

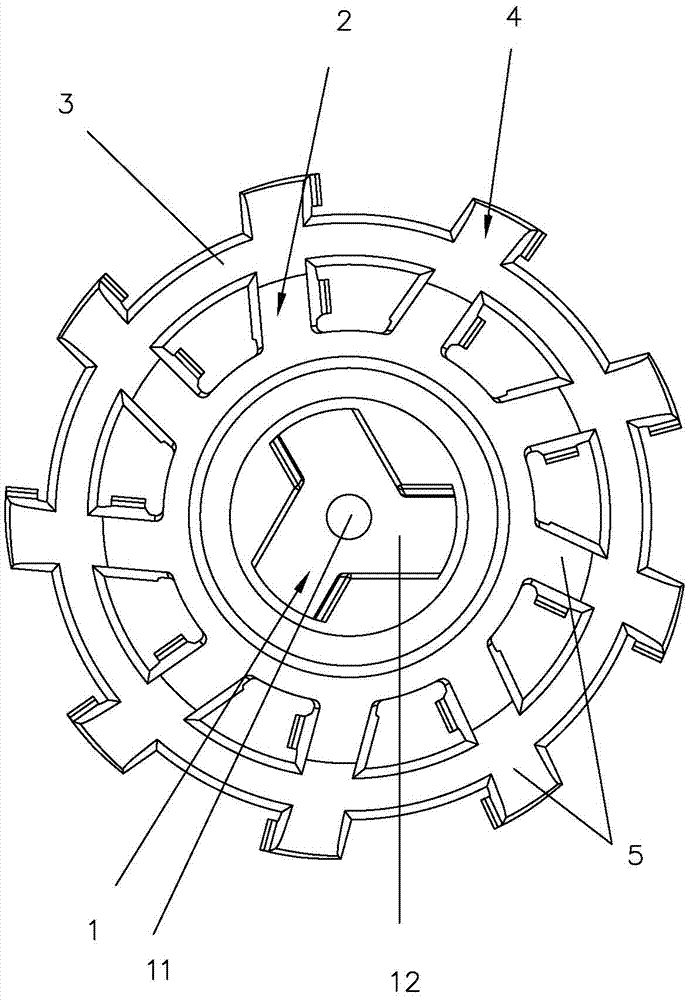

[0028] Such as Figure 1-3 As shown, a kind of ceramic razor tool of the present embodiment comprises a ring piece 3, an inner ring blade set 2, an outer ring blade set 4, a blade base 1, the inner ring blade set 2, the outer ring blade set 4 Consists of at least one blade 5 respectively, the bottom inside of the blade 5 of the outer ring blade set 4 is connected with the outer ring wall of the ring piece 3, the bottom outside of the blade 5 of the inner ring blade set 2 is connected with the ring piece 3, the inner ring wall of the inner ring blade set 2 is connected to the bottom inner side of the blade 5 of the inner ring blade set 2 and the blade base 1, and the top of the blade 5 is provided with a blade edge, and the blade 5 is made of ceramic material.

[0029] In this embodiment, the reliable connection between the blade 5 and the blade base 1 is realized through the reinforcement structure of the inner ring blade group 2-annular piece 3-outer ring blade group 4, which...

Embodiment 2

[0040] The structure of a ceramic shaver cutter in this embodiment is the same as that in Embodiment 1, so it is not redundant here.

[0041] The differences in this example are:

[0042]The ceramic material in this embodiment is a zirconia ceramic material, comprising the following raw materials in mass fractions: 80 parts of nano-zirconia, 14 parts of alumina, 9 parts of aluminum borate whiskers, 6 parts of yttrium oxide, 3 parts of kaolin, 15 parts Titanium carbide.

[0043] It can be prepared by the following steps: (1) ball milling: ball milling and mixing nano zirconia, alumina, yttrium oxide, kaolin, and titanium carbide; (2) mixing: adding 550 parts by weight of water, 1.8 parts by weight of coupling agent, 1.5 parts by weight of 1 part of binder, 4 parts of dispersant and aluminum borate whiskers, stirred and mixed for 28 minutes, spray-dried to obtain granules; (3) hot pressing: extruding the granules, sending them into the calciner for two sinterings, and one sinte...

Embodiment 3

[0045] The structure of a ceramic shaver cutter in this embodiment is the same as that in Embodiment 1, so it is not redundant here.

[0046] The differences in this example are:

[0047] The ceramic material in this embodiment is a zirconia ceramic material, comprising the following raw materials in mass fractions: 86 parts of nano-zirconia, 16 parts of alumina, 10 parts of aluminum borate whiskers, 8 parts of yttrium oxide, 4 parts of kaolin, 20 parts Titanium carbide.

[0048] It can be prepared through the following steps: (1) ball milling: ball milling and mixing nano-zirconia, alumina, yttrium oxide, kaolin, and titanium carbide; (2) mixing: adding 500 parts by weight of water, 0.1 parts by weight of coupling agent, and 0.2 parts by weight of 1 part of binder, 3 parts of dispersant and aluminum borate whiskers, stirred and mixed for 20 minutes, spray-dried to obtain granules; (3) hot pressing: extrude the granules, send them into the calciner for two sintering, and once...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com