Optimal control system and method for three-dimensional bio-printing aquogel supports

A technology of three-dimensional biological and optimal control, which is applied in the field of biomedical engineering and can solve problems such as insufficient precision control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be further explained below in conjunction with the drawings:

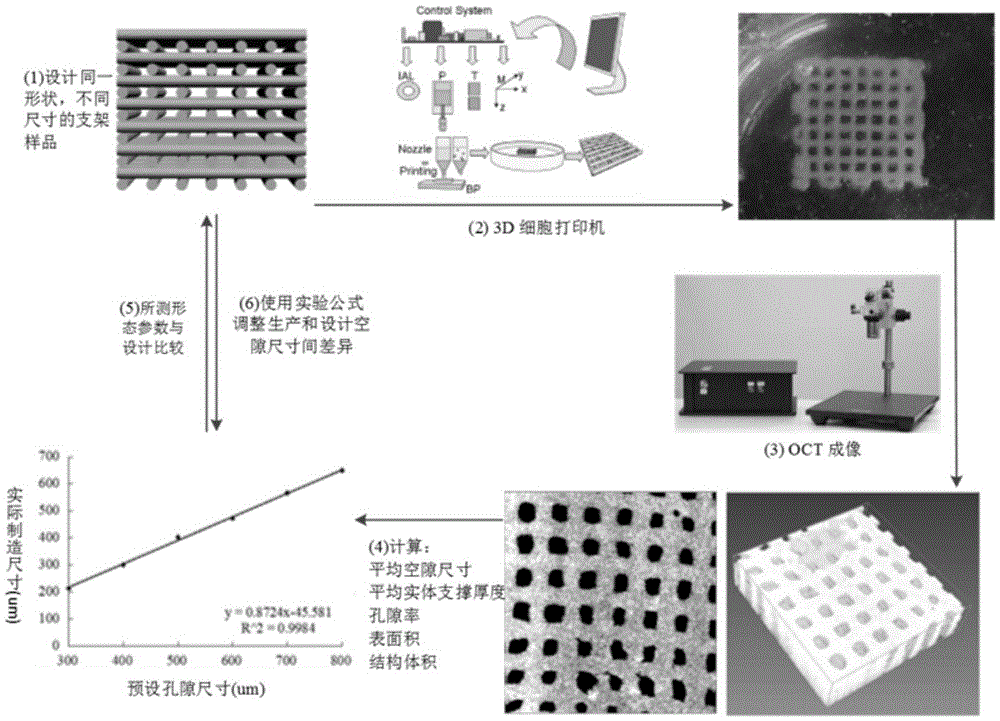

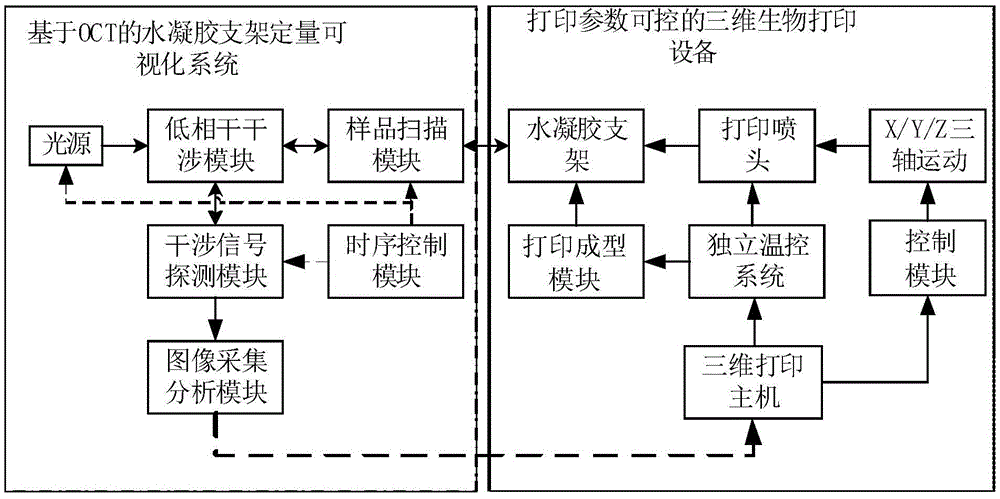

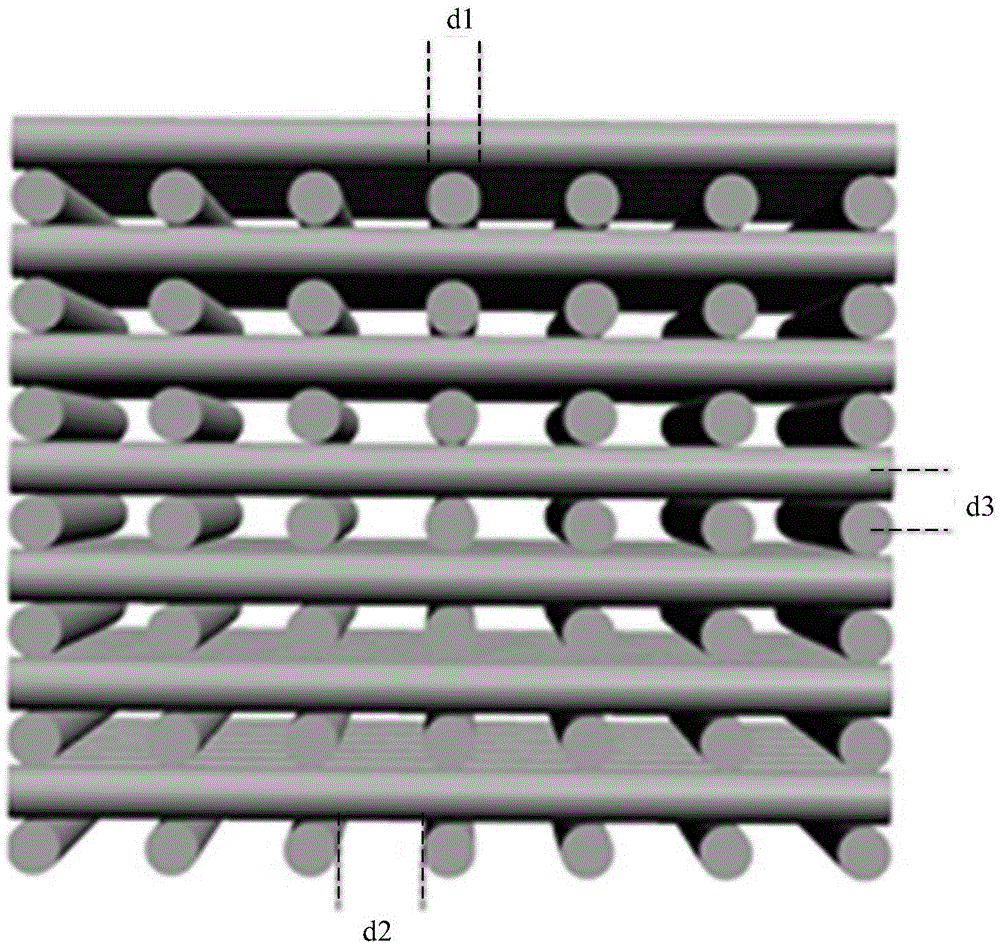

[0068] The present invention provides a precise control flow chart of the OCT-based three-dimensional bioprinting hydrogel scaffold, such as figure 1 As shown, the geometric structure of the stent to be printed is designed based on computer-aided design technology, and the hydrogel stent is manufactured using three-dimensional bioprinting equipment. The OCT system is used to quantitatively characterize the morphological parameters of the actual hydrogel stent; the deviation between design and manufacturing is compared and analyzed The correlation between the deviation and the design value, summarize the experience function; according to the experience function feedback to guide the design and printing of the hydrogel scaffold, repeat the above steps until the hydrogel scaffold consistent with the design is printed. figure 2 The block diagram of the optimized control system of the 3D b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com