Hybrid fiber regenerated concrete, and preparation thereof

A technology of recycled concrete and hybrid fiber, which is applied in the field of building materials, can solve the problems of many edges and corners, poor working performance of recycled concrete, rough surface of recycled coarse aggregate, etc., and achieve the effect of solving environmental protection problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

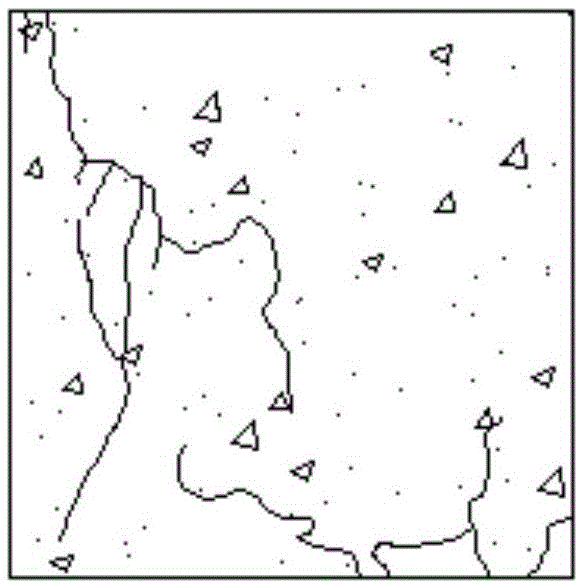

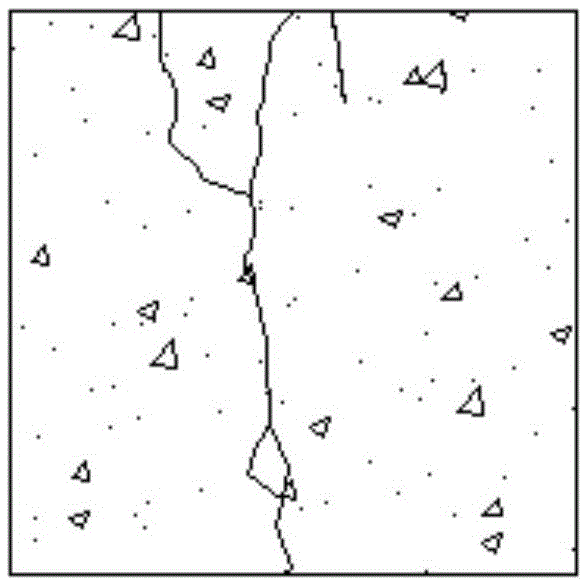

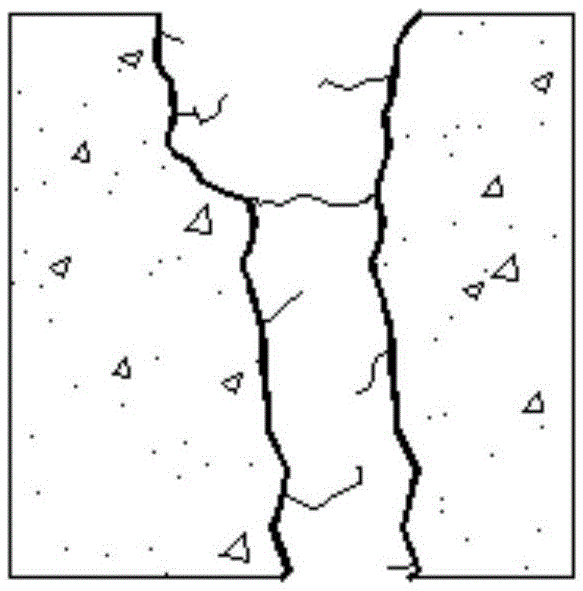

Image

Examples

Embodiment 1

[0027] A mixed fiber recycled concrete, containing per cubic meter of concrete: 0.5kg of alkali-resistant glass fiber, 0.5kg of polypropylene fiber, 400kg of cement, 100kg of fly ash, 175kg of water, 1000kg of recycled coarse aggregate and 750kg of sand.

[0028] The cement is ordinary Portland composite cement, the label is 32.5, and the configuration strength is C30.

[0029] The recycled coarse aggregate is obtained by screening the waste concrete taken from the construction site, and its particle size is 10-20mm.

[0030] The preparation method of the hybrid fiber recycled concrete comprises the following steps:

[0031] The first step is to prepare recycled coarse aggregate;

[0032] In the second step, mix the saturated surface-dry recycled aggregate with the required cement and fly ash for 1 minute, then add 50% of the required water and stir for another 1 minute;

[0033] In the third step, put the polypropylene fiber and alkali-resistant glass fiber into the remaini...

Embodiment 2

[0040] The amount of alkali-resistant glass fiber is 0.3kg, the amount of polypropylene fiber is 0.7kg, and the consumption of other components is consistent with that of Example 1.

Embodiment 3

[0042] The amount of alkali-resistant glass fiber is 0.7kg, the amount of polypropylene fiber is 0.3kg, and the consumption of the remaining components is consistent with that of Example 1.

[0043] The invention mixes a certain amount of mixed fibers (alkali-resistant glass fibers and polypropylene fibers) into the recycled concrete in a certain proportion. In hybrid fiber concrete: On the one hand, the glass fiber with high elastic modulus acts as a reinforcing material. When the tiny cracks in the concrete expand under the external load, the fiber bridges between the cracks and relieves the cracks. The stress concentration at the tip increases the crack propagation resistance and improves the crack resistance of concrete; on the other hand, the polypropylene fiber, which has a lower elastic modulus than concrete but a much larger elongation at break, can significantly improve the post-crack performance of concrete. Deformation ability, forming multi-site, multi-point cracki...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com