A kind of preparation method of inorganic coating

An inorganic coating, coating technology, applied in the field of materials, can solve the problems of corrosion resistance and thermal expansion performance to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

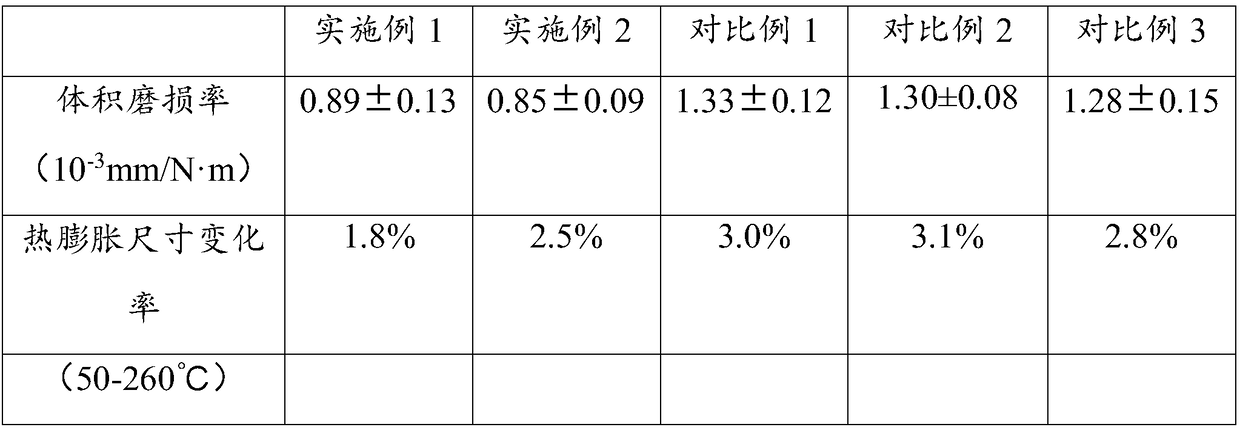

Examples

Embodiment 1

[0029] Preparation of Mo-ZrC-Mn-Ti composite powder:

[0030] Weigh the raw materials according to the following proportions: the volume content of ZrC powder is 30%, and the particle size is 10-90 μm; the volume content of Mo powder is 20%, and the particle size is 10-120 μm; the volume content of Mn powder is 10 %, the particle size is 10-100 μm; the volume content of Ti powder is 40%, and the particle size is 20-100 μm; mechanically mix in the rotary vibrating ball mill, the rotation speed of the ball mill tank is set to 150rpm (rotation per minute), the ball The material ratio (mass ratio) is 2:1. After ball milling for 3 hours, take off the ball mill jar, and the composite powder is sieved through 80 mesh, and set aside.

[0031] Prepare the coating:

[0032] 1) Pretreatment of the stainless steel substrate: place the stainless steel disc substrate (Ф60mm×8mm) treated by sandblasting (sandblasting pressure is about 0.2MPa) in an anhydrous ethanol solution for 5 minutes,...

Embodiment 2

[0035] Preparation of Mo-ZrC-Mn-Ti composite powder:

[0036] Weigh the raw materials according to the following proportions: the volume content of ZrC powder is 32%, and the particle size is 10-90 μm; the volume content of Mo powder is 25%, and the particle size is 10-120 μm; the volume content of Mn powder is 11 %, the particle size is 10-100 μm; the volume content of Ti powder is 32%, and the particle size is 20-100 μm; mechanically mix in the rotary vibrating ball mill, the rotation speed of the ball mill tank is set to 150rpm (rotation per minute), the ball The material ratio (mass ratio) is 2:1. After ball milling for 3 hours, take off the ball mill jar, and the composite powder is sieved through 80 mesh, and set aside.

[0037] Prepare the coating:

[0038] 1) Pretreatment of the stainless steel substrate: place the stainless steel disc substrate (Ф60mm×8mm) treated by sandblasting (sandblasting pressure is about 0.2MPa) in an anhydrous ethanol solution for 5 minutes,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com