Plate girder bridge reinforcing structure and construction method thereof

A technology for strengthening structures and construction methods, applied in the direction of bridge reinforcement, bridges, bridge materials, etc., can solve problems such as affecting the appearance of bridges, and achieve good reinforcement effects, simple structure, weight reduction and concrete consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

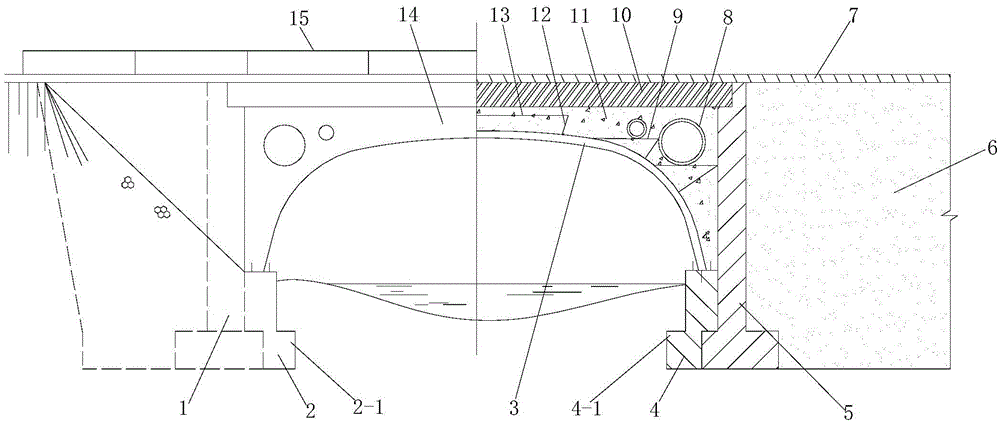

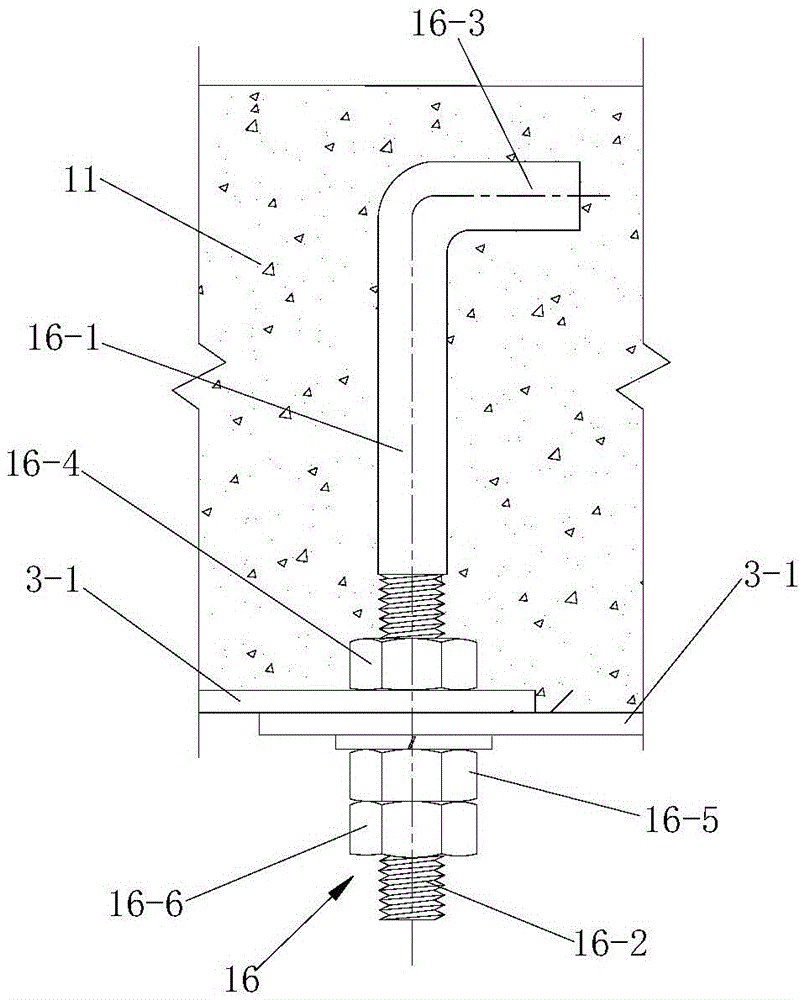

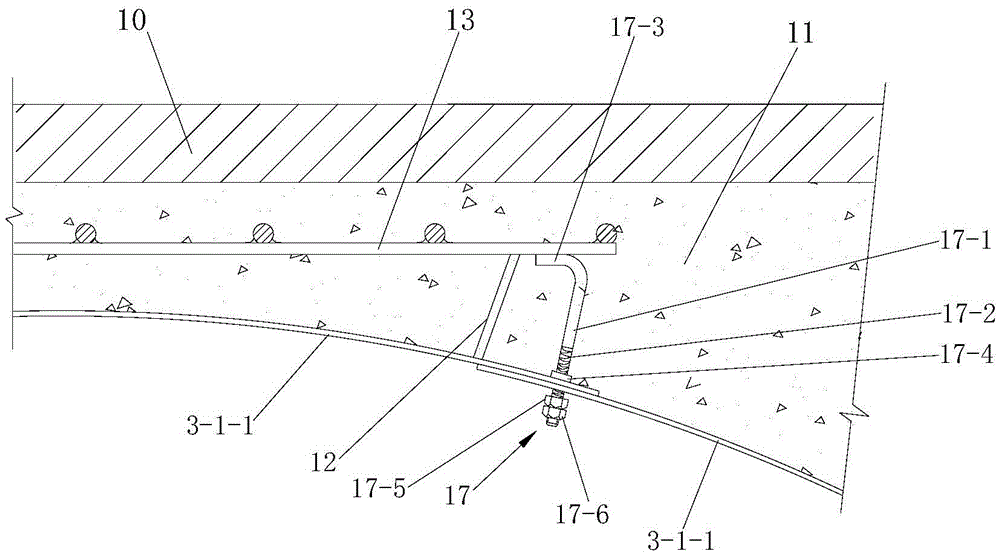

[0051] Such as figure 1 The reinforcement structure of a slab girder bridge shown includes a corrugated steel plate arch shell 3 arranged under the slab girder 10 of the slab girder bridge, a left reinforcement foundation 2 arranged on the left abutment 1 of the slab girder bridge, and a The right reinforcement foundation 4 on the right abutment 5 of the girder bridge, the left end of the corrugated steel plate arch shell 3 is fixedly connected with the left reinforcement foundation 2, and the right end of the corrugated steel plate arch shell 3 is connected with the right reinforcement foundation 4. Fixed connection, the upstream side and the downstream side of the plate girder bridge are provided with steel plate end walls 14, the upper edge of the steel plate end wall 14 is connected with the plate girder 10, and the lower edge of the steel plate end wall 14 is connected with the corrugated The steel plate arch shell 3 is connected, and the corrugated steel plate arch shell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com