Automatic tunnel waterproof material laying and hanging construction trolley

A technology of waterproof materials and construction trolleys, which is applied in tunnels, tunnel linings, shaft linings, etc., and can solve problems such as large uncertainties in human operations, hidden dangers in construction quality, and lack of guarantee for flatness and slack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

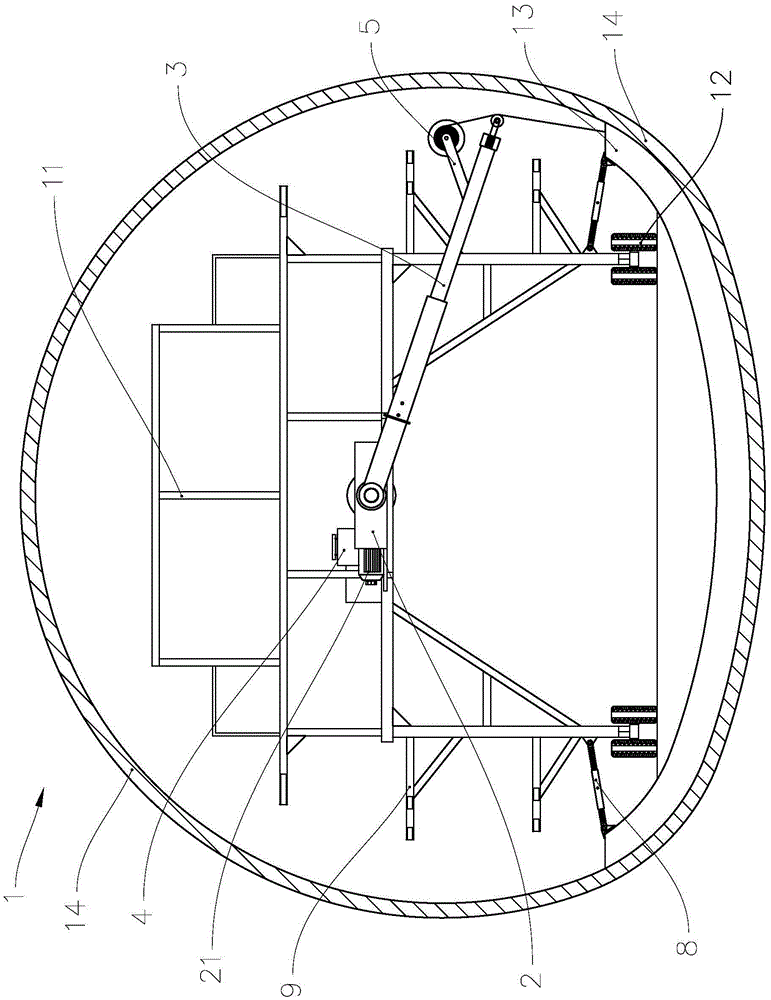

[0030] Example of automatic paving and hanging construction trolley for tunnel waterproof materials:

[0031] refer to figure 1 , figure 1 It is a reference diagram of the use status of the construction trolley for automatic laying and hanging of tunnel waterproof materials according to the present invention. The construction trolley 1 for automatic laying and hanging of tunnel waterproof materials includes a platform 11, tires 12, a driving system 2, an actuator 3, a main control console 4, a placement Mechanism 5, brake 6, driver's platform 7 and trolley fixed diagonal brace 8.

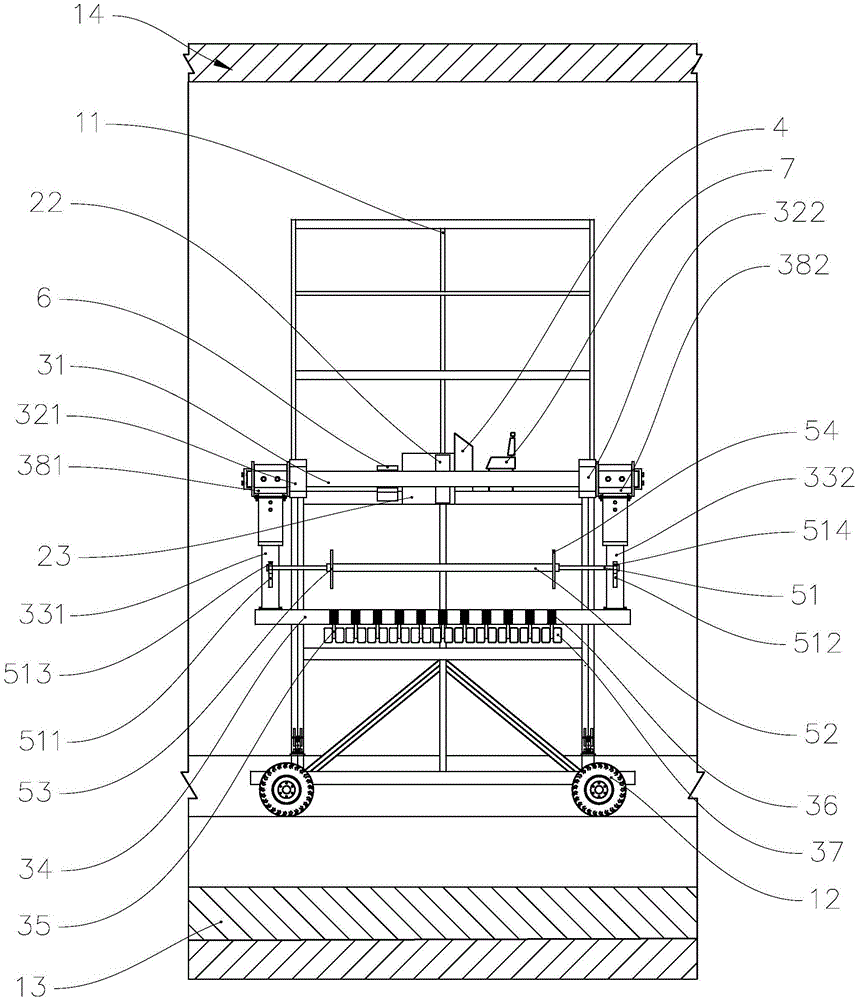

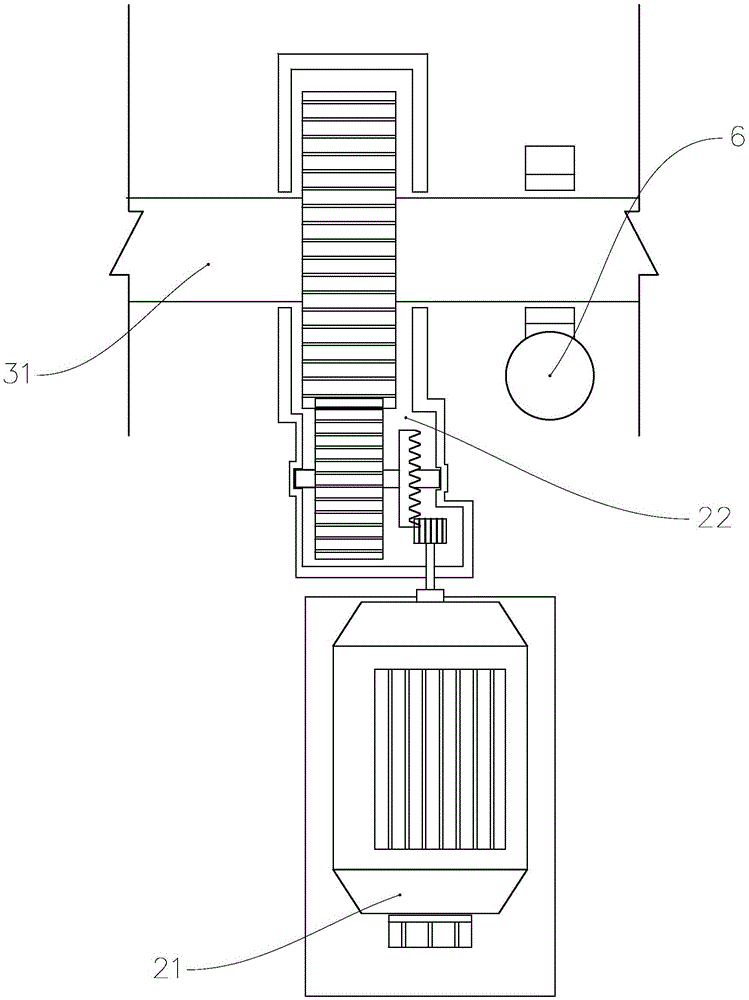

[0032] refer to figure 2 , image 3 and Figure 4 , figure 2 It is the left view of the automatic laying and hanging construction trolley for tunnel waterproof material of the present invention, image 3 It is a schematic diagram of the installation of the drive motor, reducer, rocker arm spindle and brake of the automatic paving and hanging construction trolley for tunnel waterproof materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com