Flat double-face phase-change restraining heat conducting board structure and manufacturing method thereof

A technology of phase change suppression and manufacturing method, which is applied in the field of heat transfer, can solve problems such as limitations, and achieve the effects of fast heat conduction rate, expanded application occasions and range, and good temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

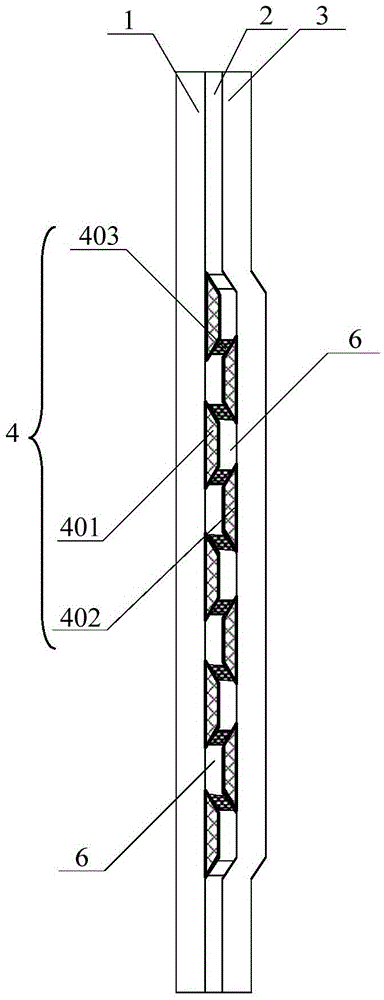

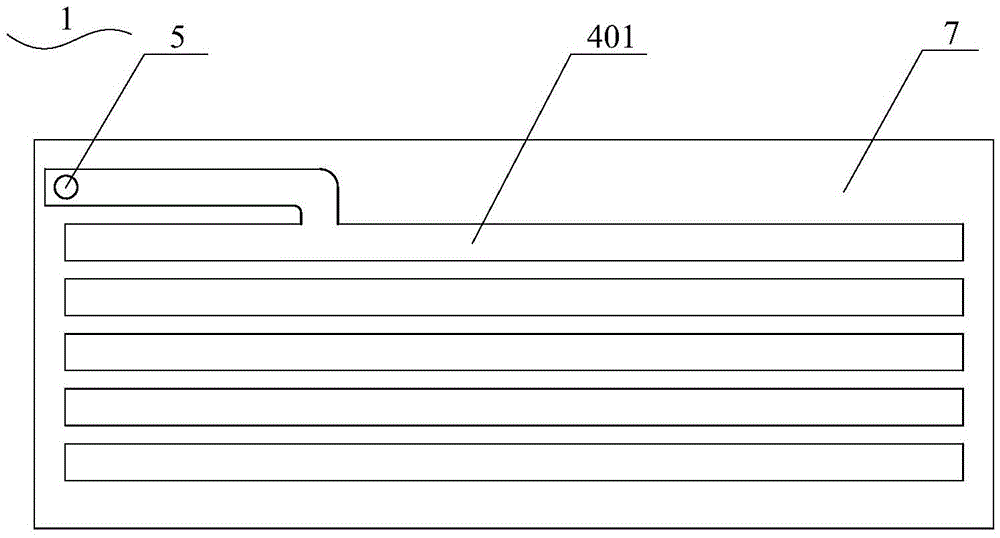

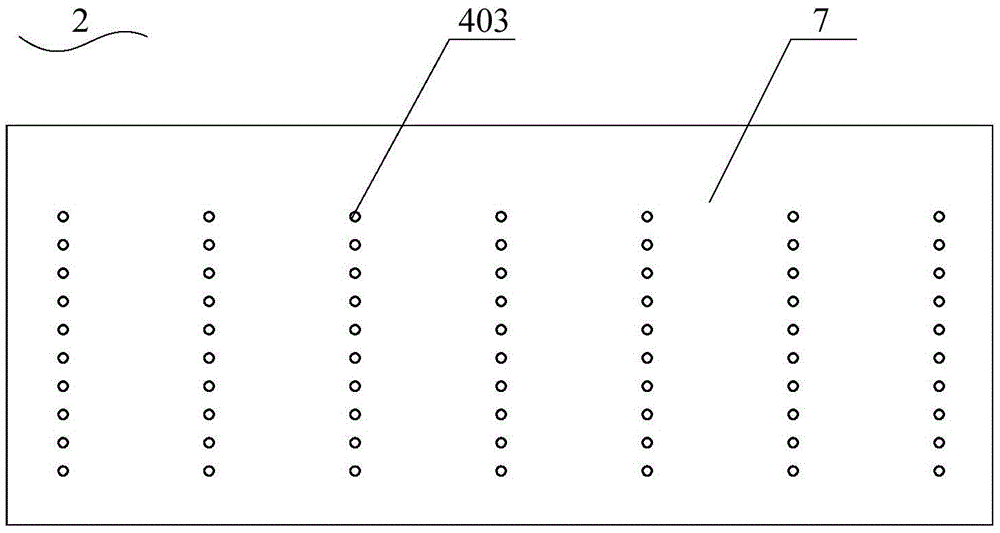

[0056] see Figure 1 to Figure 4 , the present invention provides a double-sided flat phase transition suppression heat transfer plate structure, the double-sided flat phase transition suppression heat transfer plate structure is a composite plate structure; the surface of the double-sided flat phase transition suppression heat transfer plate structure is Plane; the inside of the double-sided planar phase transition suppression heat transfer plate structure is formed with a thermal superconducting circuit 4 with a specific shape and interconnected, and the thermal superconducting circuit 4 is a closed circuit, and the thermal superconducting circuit 4 is Filled with heat transfer fluid (not shown). Both sides of the phase change suppression heat transfer plate structure are designed to be flat, which can easily realize a good combination with high-power devices and heat sink groups, and can greatly expand the application occasions and scope of the phase change suppression heat...

Embodiment 2

[0078] see Figure 5 , the present invention also provides a method for manufacturing a double-sided flat phase transition suppression heat transfer plate structure, the manufacturing method comprising:

[0079] S1: providing a total of three plates including a first plate, a second plate and a third plate, the third plate includes a raised area; smoothing and blowing clean one side of the first plate and the third plate, After forming the connecting through holes on the second sheet, roughen both sides and blow it clean; the first sheet, the second sheet and the third sheet are preferably cut and shaped by a shearing process and have the same thickness or different thicknesses. thickness of the plate;

[0080] S2: Using a graphite printing method to form interconnected graphite circuit patterns with a specific shape on the roughened surface of the first sheet corresponding to the raised area and the roughened surface of the second sheet respectively, located in the The grap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com