Gas-liquid two-phase flow parameter measuring method based on double-differential pressure of Venturi tube

A technology of gas-liquid two-phase flow and Venturi tube, which is applied to the volume/mass flow generated by mechanical effects, and the fluid flow is detected by measuring the pressure difference. It can solve the problem that the differential pressure fluctuates greatly and cannot fully and accurately reflect the pipeline. Medium fluid distribution and flow characteristics, low prediction accuracy and other problems, to achieve the effect of multiple detection parameters, good real-time performance, and simple measurement devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

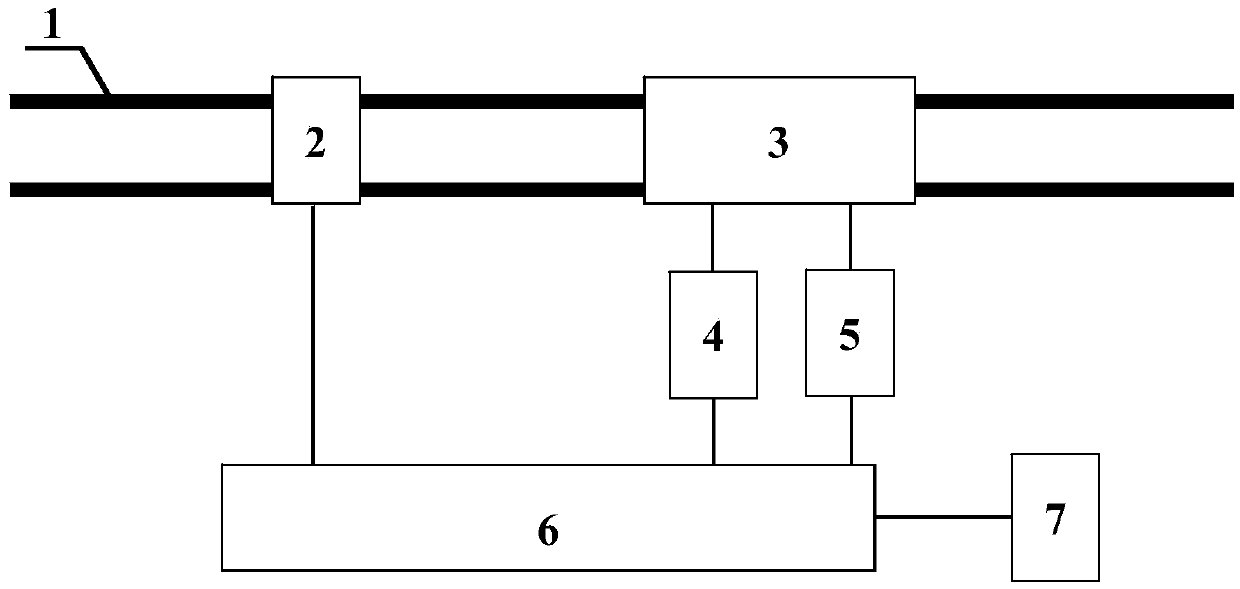

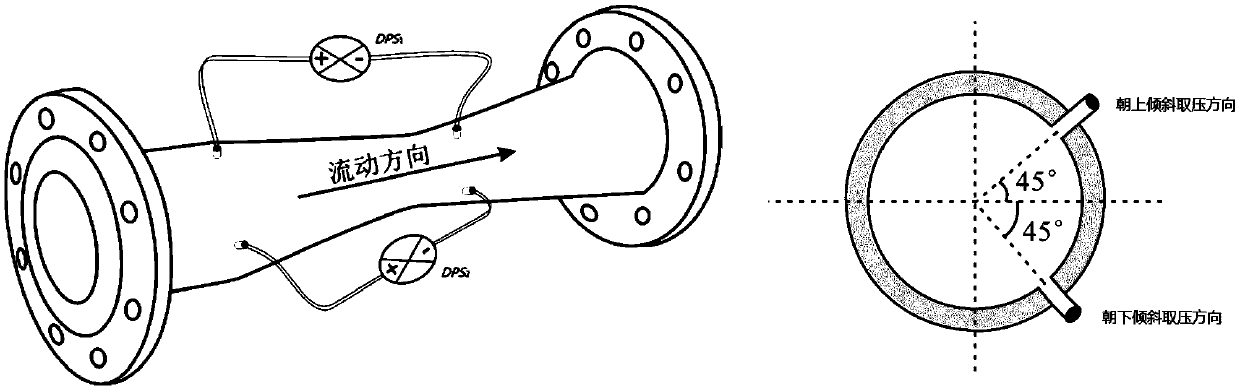

[0040] A gas-liquid two-phase flow measurement device based on dual differential pressure of Venturi tubes, including a metering pipeline (1), a pressure sensor (2), a Venturi tube (3), a differential pressure sensor (4), a differential pressure sensor (5), A / D conversion card (6), computer (7), pressure sensor (2), Venturi tube (3), differential pressure sensor (4) and differential pressure sensor (5) are sequentially arranged on the metering pipeline (1) It is connected with Venturi tube (3), A / D conversion card (6) is connected with pressure sensor (2), differential pressure sensor (4), differential pressure sensor (5), and computer (7) is connected with A / D conversion card ( 6) connected.

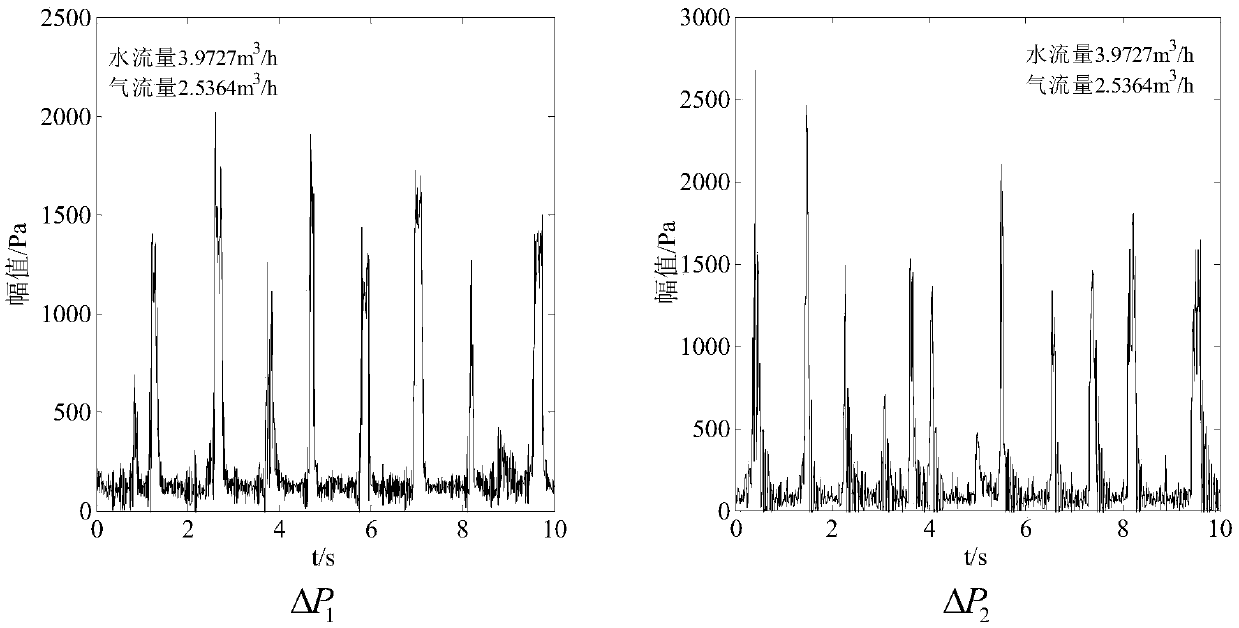

[0041] In this embodiment, the test pipe section with an inner diameter of 40 mm has a water mass flow rate of 1.02 to 4.22 Kg / s, an air mass flow rate of 0.003 to 0.021 Kg / s, a void ratio of 0.12 to 0.75, and a gas-liquid mixture with a dryness of 0.00114 to 0.0197. The method of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com