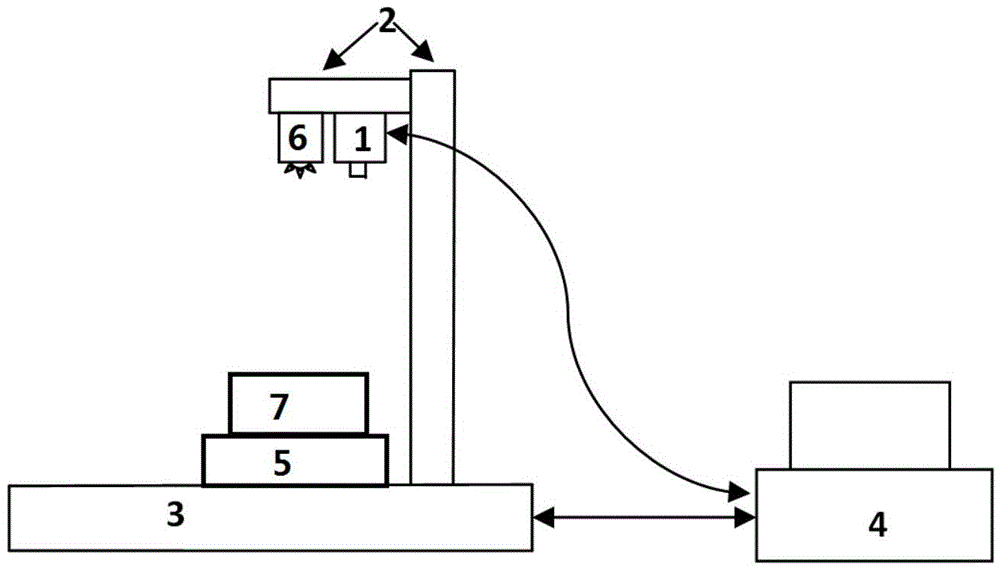

Experimental apparatus and method for detecting crazes and defects of organic glass

A technology of plexiglass and experimental equipment, which is applied in the direction of measuring equipment, material analysis through optical means, instruments, etc., can solve the problems of plexiglass damage, high requirements for the experience level of testing personnel, and heavy workload of microscope observation, etc., to achieve Intuitive effect of reduced workload, craze and defect distribution and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) Spray black and white paint spots on the surface of the speckle marker 5;

[0028] 2) digital image correlation method software and MATLAB software are installed in computer 4;

[0029] 3) Aim the CCD camera 1 at the surface of the speckle marker 5, adjust the position and focal length of the CCD camera 1, so that the surface of the speckle marker 5 forms a clear image in the middle of the field of view of the CCD camera 1, and display it in the computer 4 Calibrate how many pixels each millimeter on the surface of the speckle marker 5 corresponds to in the entire image, and take a picture;

[0030] 4) Place the plexiglass test piece 7 on the speckle marker 5;

[0031] 5) Control the CCD camera 1 to take another picture at the same position;

[0032] 6) Calculate the speckle field change before and after placing the plexiglass test piece 7 with the digital image correlation method software in the computer 4, and then obtain the light deflection angle generated befo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com