Semiconductor device and manufacturing method therefore, and electronic apparatus

A manufacturing method and technology of electronic devices, which are applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve the problem that the FCVD film cannot be transformed, and achieve the effect of improving the gap filling ability, promoting the transformation and improving the quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

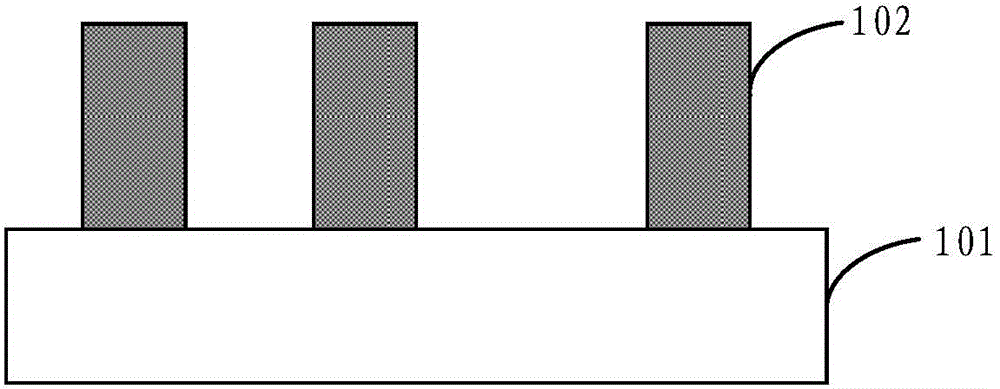

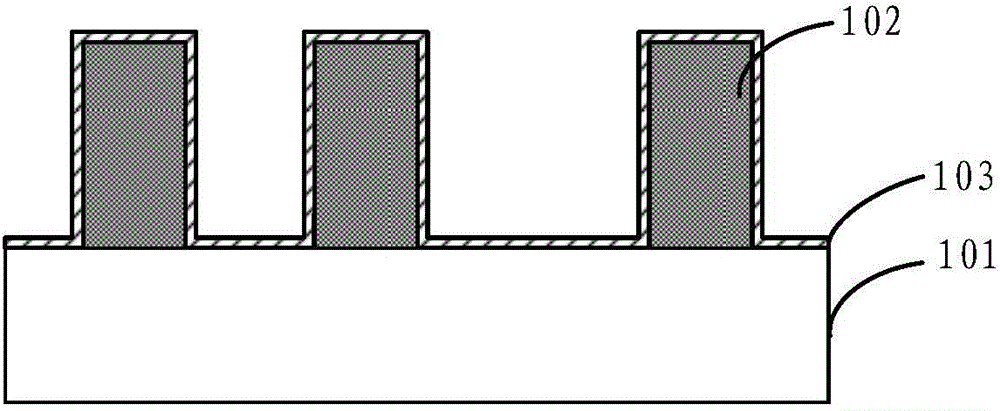

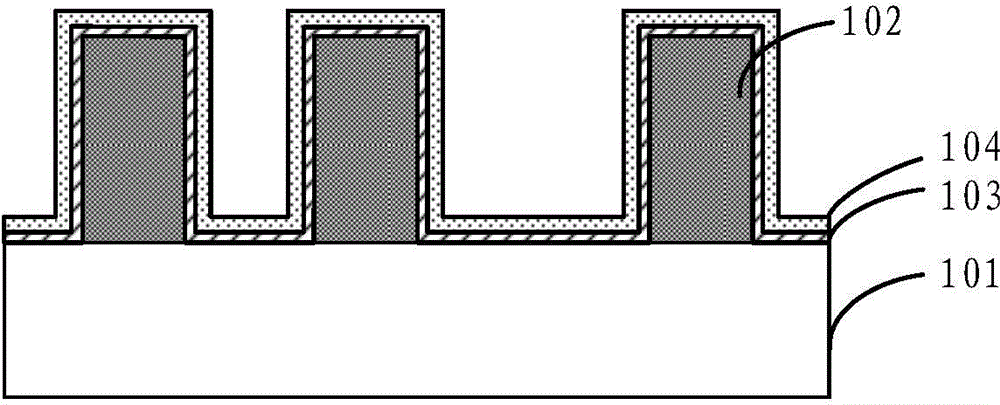

[0028] Below, refer to Figure 1a-Figure 1g and figure 2 The detailed steps of the manufacturing method of the semiconductor device proposed by the present invention will be described. Figures 1a-1g A schematic cross-sectional view of a semiconductor device obtained in key steps of a method for manufacturing a semiconductor device according to an embodiment of the present invention is shown.

[0029] First, refer to Figure 1a , a semiconductor substrate 101 is provided, and a gate structure 102 is formed on the semiconductor substrate 101 . The constituent material of the semiconductor substrate 101 may be at least one of the materials mentioned below: silicon, silicon-on-insulator (SOI), silicon-on-insulator (SSOI), silicon-germanium-on-insulator (S-SiGeOI ), silicon germanium on insulator (SiGeOI) and germanium on insulator (GeOI), etc. Isolation trenches, buried layers, and various well structures may be formed in the semiconductor substrate 101 , which are omitted i...

Embodiment 2

[0048] The present invention also provides a semiconductor device, which is manufactured by the method described in the above-mentioned embodiments. The semiconductor device adopts an oxygen-rich liner layer, which can promote the transformation of the flowable dielectric material, avoid leaving voids in the interlayer dielectric layer, and does not need to increase the high temperature thermal annealing process to improve the gap of the dielectric layer filling. Therefore, the semiconductor device provided by the present invention has higher gap-fill capability of the dielectric layer, better quality of the dielectric layer, and lower thermal budget.

Embodiment 3

[0050] The present invention also provides an electronic device including a semiconductor device. Wherein, the semiconductor device is the semiconductor device described in the second embodiment, or the semiconductor device obtained according to the manufacturing method described in the first embodiment.

[0051] The electronic device of this embodiment can be any electronic product or equipment such as mobile phone, tablet computer, notebook computer, netbook, game console, TV set, VCD, DVD, navigator, camera, video recorder, voice recorder, MP3, MP4, PSP, etc. , can also be any intermediate product including the semiconductor device. The electronic device according to the embodiment of the present invention has better performance due to the use of the above-mentioned semiconductor device.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com